Many designers have long accepted leaks as inherent to hydraulic systems, even though advances in technology should have eliminated hydraulic leakage a long time ago. Hydraulics suffers a similar identity crisis when it comes to noise. Noise certainly cannot be eliminated, but a number of products and techniques exist to at least bring noise down to an acceptable level. The problem is that noise reduction is a complex subject, and investing a great deal of time, effort, and money may produce only modest improvements.

Sources of noise

A hydraulic system's greatest contributor to noise is the power unit, Figure 1. Noise not only emanates directly from the electric motor and pump, but also is caused by pressure fluctuations in the hydraulic fluid and by components — either resulting from these pressure fluctuations or from physical vibration. Transmitting vibration of the pump-motor assembly to the reservoir can transform this physical vibration into sound - in the same way a loudspeaker transforms electromagnetic vibrations into sound.

Electric motor noise comes from bearings, the rotor and stator assembly (the characteristic hum), and, especially, the fan. A standard electric motor contains a fan with blades designed to provide cooling whether the motor shaft rotates clockwise or counter-clockwise. A fan designed for rotation in only one direction will generate less noise, so the expense of this option may be warranted if the application demands quiet operation.

Pump noise stems from rolling and sliding of bearings and pumping elements (vanes, pistons, rotors, gears, etc.), plus pressure fluctuations that result from the cyclical nature of the pumping process. Metal housings, whether part of the hydraulic pump or an electric motor, do little to prevent noise from being transmitted to the surrounding environment. Moreover, because the pump generally is coupled to an electric motor (and the coupling itself is a source of noise), noise control often involves treating the pump-motor combination as a unit. This design technique has produced power units where the pump-motor combination is submersed in oil or where the entire power unit is submerged in the reservoir. This technique uses liquid to dampen sound waves by acting as a buffer between the pump-motor housing and the surrounding atmosphere.

Valve noise has occurred in cabs of construction and other mobile equipment for years. Often, a high-frequency, random noise occurs when fluid, traveling at high velocity through the valve, undergoes a rapid and severe drop in pressure. This causes air dissolved in the fluid to form bubbles which, when they collapse, generate noise. Other types of noise — such as chattering, squealing, or buzzing — is generated when poppet-type valves do not seat properly.

Fortunately, most of these problems can be eliminated through better system design or by incorporating cushioning features into valves. A current trend replaces direct-operated valves with joystick-controlled remote electrohydraulic valves. This process of removing the hydraulics from the equipment cab offers other advantages beyond providing a quieter workplace environment.

Fluid conductors (tubing, hose, fittings), often are overlooked as noise sources. However, pressure pulsations in plumbing can distribute noise over a large area. Pressure pulsations can shake hose and tubing, causing rattling and eventual leakage.

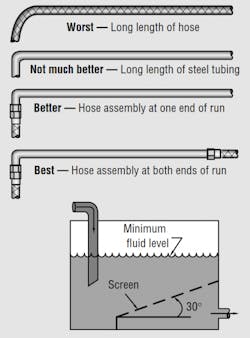

Although reducing fluid-borne noise can be complicated, many manufacturers suggest rules of thumb to help reduce noise. For example, terminating a long run of metal tubing with a section of hose at each end helps isolate noise sources, Figure 2. One might be tempted to simplify the design by instead specifying a single section of hose. Hose, however, is very sensitive to pressure pulsations, so in long sections it can be a greater source of noise than metal tubing or pipe.

Securing tubing to framework with resilient clamps eliminates rattling and banging noise. However, care should be taken not to confine tubing too tightly, because lines may need to undergo thermal expansion. On the other hand, allowing a tube to fit too loosely could cause wear as the tube constantly rubs against a metal clamp surface. Likewise, resilient grommets should be used when a hose or tube passes through a hole in framework, covers, etc.

Actuators, especially hydraulic motors, also generate noise. Hydraulic motors sometimes are considered to generate noise equivalent to that of pumps. However, hydraulic motors often operate at relatively slow speeds, so motors generally operate much quieter than pumps do.

Prevention and cure

The power unit generally holds potential for the greatest reduction in noise for a given amount of time, effort, and expense exerted. As mentioned, an optional cooling fan may reduce noise from the motor. Also, using a motor that operates at 1,200 instead of the usual 1,800 rpm may reduce noise. However, expect a 1,200-rpm motor to be larger, heavier, and more expensive.

Pump noise may be reduced by running a large pump at a lower than normal speed (which can also increase pump life) or specifying four or five small pumps for a power unit instead of the usual one or two large pumps. Size and the type of pump (piston, vane, gear, etc.), number of pumping cycles per rotation, system pressure, and, especially, pump speed all influence noise. Check with the manufacturer for assistance in determining what parameters will best suit your application.

In addition to specifying quiet pumps and motors, you can also reduce noise by:

• using vibration-damping mounts to mount the pump and the motor to a subframe,

• mounting the subframe to the power unit frame using vibration-damping mounts,

• installing a flexible coupling between the motor and pump (and aligning it properly before startup),

• using hose sections between tubing and components that are mounted to framework, and

• as a last resort, treating noise as a symptom rather than at its cause may be the only recourse for some applications. Installing sound-damping materials around the motor-pump or power unit not only adds expense and complexity to the system, but complicates maintenance and may hinder air circulation for cooling. Acoustic filters, which use internal reflections and resonant frequencies to cancel out noise, may also be effective. However, they must be tailored to the application and tend to be expensive.

Not allowing air to dissolve in hydraulic fluid goes a long way toward preventing cavitation, both in the pump and in downstream components. Cavitation usually causes noise when air bubbles suddenly collapse as fluid becomes pressurized in the pump. Air can be removed most effectively when fluid is in the reservoir. Given enough time, air will separate from the fluid, so the path from the return line to the pump inlet should be as long and with as little turbulence as possible. In addition, incorporating a fine-mesh screen promotes removal of air. Furthermore, tests have shown that positioning a 60-mesh screen 30° from horizontal may remove as much as 90% of entrained air, Figure 2.

Another method of quieting the power unit is to reduce pressure pulsations. Accumulators often are specified for this purpose, but their effectiveness is limited because they dampen pressure pulsations within a range of frequencies for a given size and precharge pressure. Moreover, accumulator calculations are complicated, and several accumulators may be required to dampen the full range of pulsation frequencies experienced by a system.

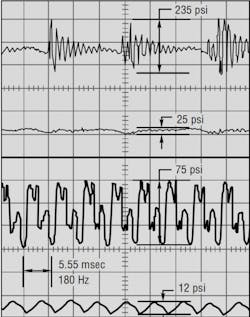

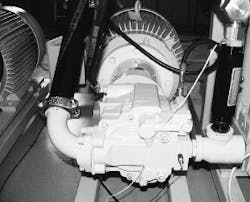

An alternative is to mount an in-line surge suppressor to dampen pulsations over a wide range of frequencies, Figure 3. One such suppressor consists of a housing containing an annular area that holds a pressurized charge of nitrogen, a cylindrical membrane, and a perforated tube, Figure 4. Under normal operation, fluid simply passes through the suppressor by entering one end of the tube and exiting the other. However, if pressure increases - from pump pulsation, for example - the fluid passes radially outward through the tube perforations, overcomes the nitrogen charge pressure, and expands the diaphragm outward. Allowing pressure fluctuations to act against the pressurized nitrogen cushions the vibration, so output pressure is much smoother - and, therefore, pump operation is quieter. Moreover, sizing is simple, because the suppressor is selected according to the size of the pump discharge line.

Finding out more

However you decide to make the hydraulic systems you design run quieter, component manufacturers prove an invaluable resource. Not only can they provide specifications on components, but they may also have useful literature containing more information on noise control of hydraulic systems. Engineering service laboratories who specialize in design and testing of hydraulic systems may also provide solutions. Whether affiliated with major component manufacturers or engineering laboratories, application engineers possess a wealth of knowledge that may include solutions to noise problems very similar to those experienced by your applications.

But resources don't end there. Dozens of books, technical reports, and papers exist to help you learn more about controlling noise in hydraulic systems. Calling on these resources may not make you an expert on the subject, but you'll certainly be more able to decide which solutions are most practical for your applications.

Keeping pneumatics quiet

Exhaust mufflers have taken on greater importance with the recent enactment of OSHA (Occupational Safety and Health Administration) Standard 1910.1000. In part, the standard mandates that noise may not exceed 90 dBA during an 8-hr day of a 40-hr week. In addition,compressed air exhaust may not exceed 4.32 ppm of oil mist contamination in any 8-hr work shift of a 40-hr work week. In addition, OSHA regulations spell out specific noise and emissions limits and time periods in which these limits are allowed. For example, exhaust noise from a pneumatic system as high as 115 dBA is acceptable. However, workers may only be exposed to this noise for 15 min within an 8-hr shift. So if workers will be near the exhaust of a pneumatic system for an entire 8-hr shift, noise to only 90 dBA is allowed.

For decades, air exhaust mufflers have been used to reduce noise and emissions of compressed air exhausts. Now, however, specific guidelines exist. Internal geometry to reduce air velocity and baffles for audio damping take care of noise; filtration takes care of the oil. But not just any filter-muffler will do.

A standard filter-muffler has a porous element to trap any solids that may have been entrained in the com-pressed air stream. Porous elements, however, are not designed to trap va-pors or liquids, such as oil. So unless the pneumatic system uses an oil-free air compressor and no lubricators, exhaust air should be routed through a coalescing muffler.

A coalescing muffler operates on the same principles as a coalescing filter. As air flows through the coalescing element, oil particles are captured by three different mechanisms: direct interception, inertial impaction, and diffusion. In direct interception, oil particles simply collide with and are trapped by filter fibers. With inertial impaction, the element's turbulent air stream throws oil particles against fibers, which trap the oil. Diffusion causes the smallest particles to vibrate and collide with each other - and eventually the element's fibers — which traps the oil.