Engineers at Bobcat Co., West Fargo, N. D., know the value of hydraulics, so they exploit its advantages to the fullest in the company's skid-steer vehicles, excavators, and other equipment. For example, Tom Connor, excavator specialist, says Bobcat's 323 excavator relies on axial-piston pumps — rather than gear pumps — to deliver the brunt of the hydraulic power. The piston pumps cost more than gear pumps initially, but because they make the hydraulic system more efficient, they produce better fuel economy. Therefore, by presenting a hydraulic system powered by piston pumps as an investment (that quickly pays for itself many times over), hydraulics becomes a positive selling point.

Connor explains that the piston pumps run quieter and can achieve longer life than gear pumps, so the advantages of piston pumps become obvious — even to buyers with little knowledge of hydraulics. He also says the 323's hydraulic system operates at 2700 psi and provides nearly 8 gpm of auxiliary hydraulic flow for operating attachments such as augers, clamps, and breakers. The system consists of a pair of piston pumps mounted in a single housing that operate independent of each other.

The piston pumps feature pressure compensation, which reduces their output flow to only that needed to maintain system pressure. Load sensing also saves energy by matching pump power output to that needed by any combination of hydraulic loads. Finally, torque limiting prevents the pups from bogging down the engine should a high load demand suddenly occur.

Another big hydraulic selling point of the 323 is a two-speed hydrostatic drive. When working at a site, operators need lowspeed travel so they can quickly and easily maneuver the excavator into just the right position. In its low-speed mode, the 323 can achieve a maximum speed of 1.4 mph. However, speed is important when operators need to move to another location, so the 323 can be shifted into a high-speed mode that can reach 2.4 mph.

The two-speed drive feature is achieved variable-displacement motors. When low-speed travel is required, pressure in a pilot circuit positions the motors' swashplates for high displacement. Therefore, fluid flow from the pump drives the motors at low speed with high torque. In high-speed mode, pilot pressure pushes the swashplates into a lowdisplacement position. With the smaller motor volume, pump flow dives the motors at higher speed but with lower torque capability.

Different drives for different tastes

In stark contrast to this drive arrangement is the Model 433 excavator. Connor explains, "The 430's FastTrack drive system works like the drive system of a skid-steer loader. You can split the power infinitely between the left and right tracks. The end result is higher torque, more precise maneuvering, and smooth acceleration.

FastTrack uses separate axialpiston pumps and high-torque motors to drive the left and right tracks. Connor says it is the first excavator to offer this feature — a true hydrostatic drive that replaces the conventional drive of conventional excavators. Connor continues, "FastTrack gives you full control of torque throughout the travel speed range. With conventional excavator drive systems, toque will peak only at maximum lever stroke. However, the 430 allows maximum torque at minimal travel speed."

More hydraulic benefits

Other hydraulic features of the 430 produce more subtle improvements. For example, instead of a single, center-mounted cylinder for powering the dozer blade, the 430 uses a pair of cylinders — one mounted at each end of the blade. This reduces the amount of dirt and debris that can build up on top of the blade structure.

The 430 also sports a redesigned arm, with hydraulic hoses routed within the width of the arm. This helps prevent the hoses from getting snagged — a potential problem due to the close quarters in which compact equipment must operate.

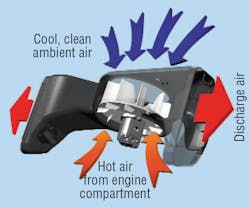

However, perhaps the biggest improvement for the 430 is its hydraulic fan drive. Because speed of belt-driven fans varies with engine speed, air flow for cooling and power draw on the engine also varies with engine speed. Speed of a hydraulic fan drive, however, is independent of engine speed. Instead, its speed is controlled according to cooling demand. Therefore, fan speed closely matches that of cooling demand, which reduces noise and improves fuel economy.

Moreover, because the fan is not driven by a belt, the radiator can be installed high on the side of the excavator. This allows drawing in ambient air from well above ground level. This reduces the likelihood of also drawing in dirt and debris, so radiators stay cleaner longer.

Click here for more information on Bobcat's Model 323 compact excavator.