High-speed sports car chases, fast and furious aerobatics, imaginative trips into volcanos, and snow skiing — these are just a few of the simulated experiences you may encounter at a shopping mall, entertainment complex, tourist attraction, or amusement park. Motion simulators provide these thrills and spills by reproducing the sights, sounds, and feelings of motion to create the impression of any of dozens of fast-paced experiences. Unlike their larger, more sophisticated cousins you'll find permanently installed at major theme parks around the world, portable motion simulators can be moved from one location to another and cost but a fraction of their high-end counterparts.

At the low-end of these portable simulators are models with enticing high-tech graphics and low-tech, electromechanical motion bases. These units require the lowest monetary investment from owners and are inexpensive to operate, but they can only handle one or two people per cycle. They also provide an entertainment experience that leaves a lot to be desired because motion may be sluggish and participants may not be completely enveloped by visual and audio effects..

On the other hand, multiple-passenger portable motion simulators provide a much more sophisticated and believable experience. Highly-responsive, multi-axis actuation produces realistic perceptions of motion, and participants are isolated from the outside environment and completely surrounded by the sights and sounds of the simulated experience. Furthermore, these simulators have a much higher throughput — 12 or more people per cycle — but carry a much higher price tag and can be cumbersome to transport from one location to another.

A market left untapped lies somewhere in between — an easily transportable simulator that can handle more than one or two people at a time, but has a purchase price and operating cost in the neighborhood of a two-person electromechanical simulator. This hole in the market has been filled by the Transport 6 portable motion simulator from Doron Precision Systems Inc., Binghamton, N.Y. The Transport 6 holds six people, so it boasts a much greater throughput than one- or two-person simulators. However, the Transport 6 carries a price tag competitive with a high-end, two-person simulator.

Donald Wenzinger, vice president of domestic entertainment simulator sales at Doron, says the Transport 6 is light enough to be rolled on its casters from one location to another by only two people and is small enough to fit through standard double doors. David C. Byerly, senior mechanical systems engineer, adds that once the Transport 6 arrives at its destination, setup is simple because its low center of gravity means it does not have to be bolted to a foundation, and it operates from widely available single-phase, 230-V power.

Advantages of hydraulics

Motion simulators that handle one or two people at a time generally are actuated electromechanically. Loads are light enough that a variable-speed motorized ballscrew provides an economical drive package for each axis. Hydraulics could work in these applications, but would cost more and offer little or no performance advantage. Once power requirements enter the 3- to 5-hp range, however, hydraulics can drive multiple axes at higher performance, lower cost, or both.

Doron engineers evaluated electromechanical systems when they first entered the entertainment market in the mid 1970s. According to Byerly, hydraulics was the clear choice for most applications. "Electromechanical systems definitely have gained some ground. But even when an electromechanical drive offers the performance we need at a reasonable price, we have found hydraulics to be the most reliable and responsive drive system. Hydraulic actuators also take up less space than a motor and ballscrew, and we can always find space to locate the hydraulic power unit."

Byerly also cites service life as an advantage hydraulics has over electromechanical systems for these applications. "Life of a ballscrew is rated like a bearing: a finite number of cycles, distance traveled, or hours of operation. Maintaining proper lubrication, cleanliness, and alignment is essential to a ballscrew achieving its rated life. A carefully engineered hydraulic system, on the other hand, excludes contaminants and filters out those that do happen to get into the oil. Ballscrews do not have this opportunity to remove contaminants unless a sophisticated pressurized lubrication system is incorporated."

Wenzinger explains that manufacturers of electromechanical motion simulators often attempt to gain a competitive edge by presenting leakage and noise as major disadvantages inherent to hydraulically powered motion simulators. "But," reveals Byerly, "leakage has not been a problem with our simulators as long as they are installed and maintained properly. We use O-ring type fittings to prevent leakage, and rod seals hold up well because they normally are not subjected to anything real hostile. It's not like a backhoe, where mud and sand get caked onto the rod. Our literature specifies that the simulators should be installed in relatively clean environments. One operates near an ocean-side boardwalk. But because it is inside a tent, it is not exposed directly to the sandy, salty atmosphere of a marine environment — and it doesn't leak. So our systems are helping to dispel the myth that hydraulic systems have to be messy.

"Also, noise has not been a big concern. With hydraulics, most of the noise is generated by the hydraulic power unit. Granted, the power unit makes more noise than a single ballscrew and motor assembly. But with hydraulics, noise comes from a single source, so it is easier to isolate than noise coming multiple sources and different directions, as is the case with a simulator using multiple motorized ballscrews."

Lights, camera, action

Wenzinger says that many simulators provide six axes of motion. "But because a full six axes of motion are difficult for the human senses to detect, we chose three axes for the Transport 6 — roll, pitch, and vertical translation. These provide the best dynamics for a realistic simulation of motion. Although six axes might add a little to a rider's experience, it would add substantially to the cost and certainly price the Transport 6 right out of its intended market.

"With its three degrees of freedom motion system, the Transport 6 provides a believable sensation of motion. After all, most of the sensation of motion comes from the visual presentation; the physical motion primarily reinforces the motion implied by the visuals. But it is important that the physical motion be carefully executed and in close synchronization with the visuals, otherwise, participants could develop motion sickness."

Byerly reveals that the visual portion of the program is shot on 35-mm film, edited, and recorded on laser videodisc. He says that if programs were shot directly on video tape, images would be limited by the image quality of the tape. The 35-mm film, however, has much greater resolution and color reproduction than video tape does. So the high-quality images captured on film can be used for future programs that will use high-definition video equipment. Along with the visual images, a high-fidelity soundtrack is stored on the videodisc, as is an electronic index of each video frame.

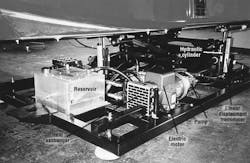

To create the Transport 6's motion, programmers play the videodisc and maneuver joysticks to tilt the motion base left, right, up, or down while watching the video display. This is done in segments, so portions can be re-recorded, merged together, and fine-tuned to achieve a motion profile that closely matches what is seen in the video. The finished motion profile is then electronically stored in a motion controller. The motion controller then re-creates the programmed motions by commanding the proportional valves, which direct hydraulic fluid flow into and out of the cylinders. The control loop is closed by a linear-displacement transducer (LDT) mounted alongside each cylinder. The motion controller compares cylinder feedback signals from the LDTs to those electronically stored in the motion profile.

A proprietary computer controls and monitors overall operation. The computer does not command the motion controller to begin the motion sequence unless all interlocks have been closed. These include switches to indicate that doors are closed and latched, cylinders are in the home position, etc. Once the motion program begins, the computer monitors operation by comparing feedback signals from each LDT to programmed values at each video index increment. These updates occur up to 30 times per second.

Hydraulics hardware

Driving the Transport 6's hydraulic system is 3-hp electric motor close-coupled to a variable-displacement, axial-piston pump. A 10-gallon reservoir provides a constant source of fluid, and a heat exchanger keeps fluid at a temperature well below what would be considered hot. A 5-gal. accumulator with a 650-psi precharge supplements pump flow when needed during brief periods when flow to 15 gpm is needed.

Pump — The hydraulic system is driven by a Bosch Rexroth A10V10 pump. It has a maximum displacement of 10cc/rev. and features pressure compensation to stroke the pump to zero displacement when pressure reaches the compensator setting - in this case, 1000 psi. According to Jon Yuhas, manager of Rexroth's Northeast Technical Office, Nashua, N.H., the pump's noise reduction features make it especially appropriate for the application.

He says that the geometry of the pump's timing plate dampens pressure changes that occur when fluid rapidly becomes pressurized and depressurized as it moves through the pump. Left uncorrected, these rapid pressure fluctuations produce ripple — a significant source of pump noise. The A10V10 pump also has wide flow passages to reduce turbulent flow, another potential cause of pump noise.

Yuhas continues by pointing out that the close coupling also is important. The electric motor's end plate is configured into an SAE A flange - a two-bolt configuration with splined shaft. The pump mates directly to the motor, and because a shaft coupling is not needed, noise otherwise generated by the coupling is eliminated. Yuhas states that the pump is so quiet that it makes less noise than the 3-hp electric motor driving it.

Further contributing to quiet operation is the actual design of the hydraulic system. System pressure is limited to only 1000 psi, even though all components are rated for at least 3000 psi. The relatively low pressure tends to produce quiet operation, and the pump runs at near zero displacement for much of an operating cycle. Operating the pump at near zero displacement not only generates less noise, but keeps the hydraulic system running cool.

Proportional valves — From the pump and accumulator charge/discharge circuit, fluid then is routed in parallel to three double-solenoid, spring-centered proportional valves. Yuhas reveals that the valves, Rexroth 4WREE6-V, have a chamfer and notches on the corners of the spool. These features create essentially a zero-lapped spool to provide maximum response while preventing internal port-to-port leakage - which could otherwise cause cylinder positioning error. An integral LVDT enables the valve to self-correct any spool position error by monitoring spool position.

Yuhas adds that on-board electronics compensate for flow irregularities when the valve shifts through its center position. This simplifies control wiring because the valve can be run directly by the analog signal from Doron's proprietary computer control.

In addition to the proportional flow capabilities of the valves, metering valves are piped in series to each cylinder port. These serve as safety devices to limit flow to 5 gpm from the cap end and 3 gpm from the rod end of each cylinder.

Cylinders — Finally, fluid reaches three double-acting cylinders, each with a 1½-in. bore, 10-in. stroke and 1-in. rod. Cushions built into both ends of each cylinder limit deceleration in the unlikely event of system failure. Motion is transmitted from the cylinders to the motion platform through spherical rod ends. A large, centrally located universal joint constrains the three axes of motion and works in concert with the spherical rod ends to prevent side loading, which could reduce cylinder life and reliability.

Position feedback — Doron engineers chose to use a potentiometric LDT for position feedback. Sometimes referred to as linear pots, these LDTs are among the most compact and least expensive designs for providing a continuous feedback signal indicative of piston position. A non-contact LDT — such as a magnetostrictive design - could have been used, but would have increased the cost of the system substantially.

Often, motion bases mount the LDT inside the cylinder. This is done to conserve space and protect the LDT from a potentially hostile environment. It is more costly to mount the LDT inside the cylinder, so Doron opted for the external mounting because space was available alongside the cylinder and the environment is not hostile.

Byerly explains that, "The linear pot delivers the performance and life necessary for all applications of the Transport 6. And because the LDT is not mounted inside the cylinder, it's easy to replace. This takes very little time, and the cost to replace the linear pot even two or three times still is far less than the initial cost of a single non-contacting LDT."

Because these simulators are portable, Byerly says, most components are readily accessible. "If it took a lot of time and effort to change an LDT, we could justify paying the higher price of a non-contact LDT. But most components on these machines are very accessible, so service and maintenance is quick and easy. I understand, though, that this is not the case with equipment mounted permanently in an area with limited accessibility. In cases like those, you would need to use as many components as possible with an infinite life rating because having to service or replace them would be expensive. So in a way, the portable configuration is somewhat of a luxury from a design and maintenance standpoint."

Filtration — As with any hydraulic system, the hydraulics of the Transport 6 relies on clean fluid for high reliability and long life. Byerly explains, "We don't do anything fancy with filtration. We have to deal with the usual airborne contaminants and occasional debris that works its way into the working envelope of the cylinders." The standard filtration package for the Transport 6 consists of a 10-µm breather cap and a 10-µm pressure filter just downstream from the pump.

"Probably the greatest potential source of contamination is when a simulator is transported from one location to another, explains Byerly. "About the only places where contaminants can enter the hydraulic system are at the piston rods and reservoir breather. Neither presents a problem, though. When a simulator is transported, all cylinders are in their fully retracted position, and we provide a cover to be placed on the breather to seal it. This isolates the reservoir from the environment when the machine is in transit.

All-around benefits

One of the keys to making the Transport 6 price competitive with electromechanical simulators was keeping the design and construction simple. The higher performance of hydraulics produces a better experience for riders, and its six-passenger seating makes the Transport 6 by far a better value than its electromechanical competitors. Its portability and single-phase electrical operation make it easy to install.

But the benefits of the Transport 6 go beyond those that can be realized by owners and passengers. Its high reliability, leak-free operation, and easy maintainability make the Transport 6 a convincing example that hydraulic systems can offer high performance without the negative stereotypes often associated with them.