General Foods coffee-grinding plant receives 180 tons of coffee beans daily from all the coffee-producing countires in the world. Raw coffee beans, packed in traditional burlap sacks, arrive in large containers. From these containers, the sacks are opend and dumped onto a conveyor belt that transports the beans to stations for weighing and cleaning before they are stored in silos.

Unfortunately, some sacks rip in transit, others split open when the container is tipped, and there is always some spillage as the sacks are emptied. Previously, these beans fell to the floor near the conveyor belt. The waste was considerable — totaling several tons of coffee per year — and the risk of workers slipping on spilled beans created a very real safety hazard.

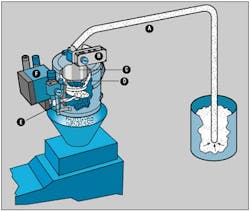

General Foods eliminated these problems by placing large funnels beneath the conveyor joints and at the tipping station to collect nearly all spillage. The funnels gravityfeed beans to collection containers from which vacuum conveyor pipelines return them to the system.

Power for this conveyor system is provided by automatically controlled, multi-stage ejector-type vacuum generators. Requiring only a supply of compressed air, these compact generators were easy to install, even in the limited space of this retrofit project. With no moving parts, maintenance and operating downtime are minimal.

Along with the monetary saving realized from salvaging the spilled beans, the vacuum system also:

• takes much of the heavy lifting out of the operation

• cuts down on dust

• protects the coffee in a closed environment

• generates no heat, and

• produces very little noise.

The vacuum generators installed by General Foods were built by PIAB Vacuum Products.