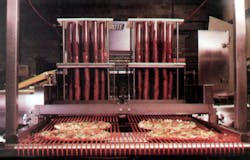

Pizza is arguably America’s favorite snack food, and pepperoni is one of America’s favorite pizza toppings. Food-processing equipment manufacturer Grote Co. Inc., Columbus, Ohio, builds Peppamatic machines to slice pepperoni precisely and apply the slices in a selected pattern on pizza crusts moving through the machine on a conveyor. The Peppamatic Model 1514-2 — with two independent slicing heads that hold the uncut pepperoni— uses electrohydraulic motion control to match head actuation with the position and velocity of the moving crusts as they approach on the conveyor. As a result, the pattern and placement of slices stay consistent, and manual adjustments are eliminated.

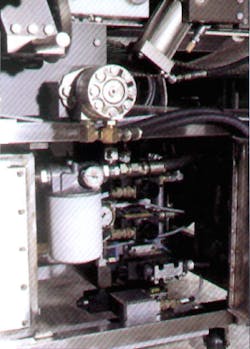

An electronic motion controller coordinates the slicing heads and the conveyer. While a nickel-plated Parker Nichols hydraulic motor, controlled by a Parker Hannifin D1FX proportional directional-control valve, powers the conveyor, an optical encoder with quadrature output provides position-feedback signals to the controller.

A pair of Parker Hannifin cylinders, one on each slicing head, await individual commands from Parker electrohydraulic servovalves. The cylinders are fitted with externally mounted Temposonics II magnetostrictive position sensors. (Such sensors frequently are installed in a cavity bored in the piston rod, but these 1-in. pistons have only 5/8-in. diameter rods.) By electronically slaving the Temposonics sensors to the optical encoder, the motion controller strokes each slicing head cylinder at the exact moment that the conveyor delivers a crust underneath it.

Diffusion sensors detect reflected signals from pizza crusts on the conveyor as they approach the slicing heads. After the sensor detects a crust, the controller counts down the appropriate delay until the crust moves directly under the head. Then the automatic slicing operation begins.

An integral power unit supplies the 1,000-psi hydraulic system. Because of the high speeds involved, the Peppamatic 1514-2 drives its Parker variable-displacement piston pump with a 15-hp electric motor. Another hydraulic function actuates cylinders that raise the machine's heavy top assembly to facilitate cleaning. (The USDA-approved machine is designed for washdowns using harsh commercial sanitizing agents; stainless steel, Delrin plastic, and hard-coat anodized aluminum are among the materials.)

Click here to watch a video of different Peppamatic machines in action.

Tony Thomas, mechanical engineer, J. E. Grote Co., Inc., Columbus, Ohio, provided details on this equipment.