CCEFP and Georgia Tech researchers are working on new materials to make hydraulic systems quieter

Appeared in print as "Cancelling noise at its source"

Injection molding machines produce cyclical noise, and the bigger the machine, the louder the noise. Moreover, the larger the machine, the more likely that it uses hydraulics. Furthermore, high-volume producers generally use multiple large machines within a single plant. This can make noise from the machines — including the hydraulic systems — a significant problem in the workplace.

However, noise generated by hydraulic systems is not restricted only to injection molding machines, or even stationary equipment. Noise should be a concern for any designer of industrial and mobile hydraulic equipment. Whether your restrictions are regulatory compliance, passenger comfort, or environmental, hydraulic noise can be a formidable opponent. With increasing attention given to hydraulics as it breaks into nontraditional markets, such as hydraulic hybrid vehicles, noise will become an even greater concern.

For system designers faced with reducing fluid-borne noise, rules of thumb and discrete components can be applied — such as plumbing practices and noise suppressors. But these methods are either of limited effectiveness or have some significant downside. For example, suppressors have been used with success but require regular maintenance.

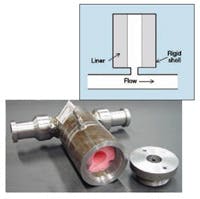

Research at the Georgia Institute of Technology seeks to combine the performance and compactness of suppressors without the need to recharge a bladder. A solid, engineered liner material is in development that remains compliant at high static pressures and is installed in any of four traditional noise control components — an in-line silencer, a Helmholtz resonator, a tuning coil, and a Quincke tube.

Basics of hydraulic noise

The physics of sound and sound generation are the same for hydraulic oil as they are for air; the major difference is the speed of sound. The speed of sound in hydraulic oil is approximately 1400 m/sec — far greater than the 343 m/sec in air. This means that the wavelength for the same frequency is four times longer in oil than in air. In addition, noise control devices — such as silencers, Helmholtz resonators, tuning cables, and Quincke tubes — scale with the wavelength. Longer wavelengths mean larger devices unless performance is sacrificed. In the past, this has meant that, except for suppressors, traditional devices have not been viable solutions for fluidborne noise due to their size.

Once fluid-borne noise is produced in a system, it may be controlled by either reflection, containing it between a silencer and the source, or dissipation by conversion into heat. Reflection takes place at any boundary where the acoustic impedance changes — at fittings, the change from a metal tube to hose, at a valve, from one size tube to another, etc. With hydraulics, these effects can be minimal. A much more significant impedance change can be introduced by a compliant wall where the speed of sound is much lower. The slower sound speed then becomes a significant impedance change where incident acoustic energy is reflected back toward the source.

Traditional solutions

Again, many different methods are used to reduce fluid-borne noise and its effects. Pump designers continue to refine the relief ports on the valve plates of axial-piston pumps. The use of hoses decouples rigid sections of metal tubing and isolates structural vibrations. Hose also has some attenuating properties for fluid noise; however, hose also needs to contain the pressure of the system and must have a very stiff steel reinforcing braid.

Network modeling gives designers insight into standing wave effects that can be mitigated by modifying component impedances or hose lengths to reduce audible noise. Designers can also control the surfaces to which hydraulic lines are mounted, ensuring that resilient mounts are used or the surfaces are appropriately heavy or stiff to reduce transmitted vibrations. Accumulators may be used as low-pass filters with a very low cutoff frequency.

Finally, hydraulic noise suppressors may be applied near the outlet of the pump to contain the fluid-borne noise and prevent it from propagating down the system. These suppressors are composed of a rubber bladder, pressurized with nitrogen to approximately 50% of the static pressure at the installation point. A set of perforated annuli restrain the bladder and add some viscous drag effects. Suppressors introduce compliance by the nitrogen-charged bladder’s lower bulk modulus than the fluid. The disadvantage to these devices is the slow diffusion of nitrogen through the bladder, resulting in the need to periodically recharge the suppressor.

Innovative solutions

Research in progress at the Georgia Institute of Technology’s Integrated Acoustics Laboratory seeks to develop innovative solutions to reduce fluidborne noise. The research is funded by the Center for Compact and Efficient Fluid Power, a multi-university research program headquartered at the University of Minnesota. The goal of the project at Georgia Tech is to create noise control devices for fluid power systems that are both compact and effective.

The focus is on developing solid, engineered materials that can be used to line the interior of traditional noise control devices and remain compliant at the working pressure. Such a solid engineered liner does not need to be pressurized or maintained and may be easily interchanged for different systems or operating conditions. The compliance lowers the speed of sound within the device, which may lower the size relative to an unlined device.

Four separate prototype devices have been constructed to test the performance of the liner:

- an in-line silencer,

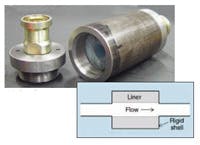

- a Helmholtz resonator,

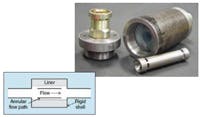

- a tuning cable, and

- a Quincke tube.

The metric used to quantify the performance is the transmission loss, TL, reported in decibels dB. A Bel is a measure of the ratio of transmitted acoustic energy to incident acoustic energy. Measurements are made using an ISO 15086-based test rig, which is the standard for speed of sound and TL measurement.

Preliminary test results for the in-line silencer show comparable performance to bladder-style suppressors at 300 psi, providing at least 25 dB of TL from 200-2000 Hz. In addition, modeling efforts have accurately characterized the inline silencer’s performance and have been used to determine the material properties at elevated pressures — aspects not known by the manufacturer of the liner material. A lined silencer that lacks the engineered structure behaves identically to a silencer with no liner at all, further demonstrating the importance of the structure of the liner to its performance at higher pressures.

The liner has also been installed in a Helmholtz resonator. A Helmholtz resonator is the acoustic analogy of a mass-spring-damper and acts as a notch filter. The compliance of the liner at elevated pressures lowers the speed of sound within the cavity of the resonator, thus making the wavelengths shorter. This makes the resonator appear acoustically larger because its dimensions are larger relative to a wavelength at the frequencies of interest. As a result, the prototype has a resonance frequency much lower than an equivalent, unlined device. A conventional device would need a cavity volume two orders of magnitude as large as the lined prototype to have the same resonance frequency. This also allows the device to be tuned to a specific resonance frequency simply by interchanging the liner in the cavity.

Two additional devices, a tuning cable and a Quincke tube, can also be created using the shell and liner from the in-line silencer and a rigid annulus. A tuning cable is a concentric quarter-wave resonator. Phase cancellation occurs at the reconnection point for a wavelength that is four times the length of the annular path. The outer annular path is exposed to the engineered liner, so it has a lower sound speed than an equivalent, unlined device. This permits a much lower resonance frequency, meaning the device can be more compact than an equivalent, unlined device with the same resonance frequency.

Likewise, a Quincke tube is a half-wave resonator where the sound speed in the outer and inner annular path is different. This also leads to phase cancellation at the reconnection point.

All of these devices affect attenuation in periodically-spaced frequency bands. They may be ideal for fixedspeed applications where pump harmonics are strong and wellknown.

Conclusion

Reduction of fluid-borne noise is difficult because of the high speed of sound, and, thus, long wavelengths, in hydraulic fluid. An engineered, solid liner material that remains compliant at elevated pressures is the key to reducing the fluid-borne noise which is transmitted into the system from the pump or other noise-producing component. This, in turn, lessens the deleterious effects of fluid-borne noise on components and reduces the amount of structural vibration and airborne noise. Current work includes developing and refining analytical models for the devices, improving the test capability to 5000 psi, and producing liner materials for higher pressures.

Nicholas Earnhart is a PhD candidate and Kenneth Cunefare is Professor of Mechanical Engineering at Georgia Tech. For more information, e-mail [email protected], [email protected], or view the complete paper archived with the article on our website.