Cable-free, standalone WPLS-160 mobile lift columns enable technicians to set up almost anywhere inside or outside the shop, raise a vehicle hydraulically as high as 67 in., and get the work done faster. Manually moving and aligning individual lift units is made easy by virtue of the low-center-of-gravity design, spring-loaded wheel components, and well-leveraged positioning handle.

Technicians routinely raise cars and trucks with lifts to work underneath them. However, dedicated in-ground lifts take up valuable space when they're not being used; and opening a lane to get vehicles to and from such a lift requires more floor space and can be a timeconsuming annoyance. Portable lifts often make more sense — technicians move the lift to the vehicle. But when cables and hoses are part of the portable lift, they can drag and wear when the unit moves. In fact, cables and hoses on the floor are the Achilles' heel of mobile lifts; they can be hazardous to technicians who work among them and they may interfere with other equipment the technicians want to use in the same area.

Designers at Gray Automotive recognized that stand-alone portable lifts — one for each wheel — would eliminate most of these problems. If batteries powered the lifts individually, and they were operated by wireless remote control, there would be no external cables to deal with. If the lifting power was hydraulic, instead of the more common mechanical machine-screw type, the lift could lower under gravity, simplifying the controls and conserving on-board energy.

Gray incorporated these concepts into the WPLS-160 wireless portable lift system. Each unit is self-contained, using DC power to drive its power unit. The power source is designed around a commercial deep-cycle 12-V battery that holds long-lasting charges and is concealed at the base of the column. Each unit also includes an on-board charging system that plugs into any readily available 110-V outlet to recharge the battery during off-hours. (DC eliminates the hidden up-front costs of high-voltage power installation.) The self-contained design provides great flexibility, allowing almost unrestricted use of the lift throughout any shop, with no concern about the location of electrical outlets.

All for one and one for all

Hydraulics provide safety and efficiency

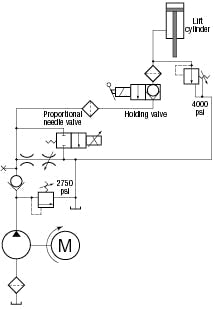

The hydraulic pump in Gray Automotives self contained, wireless lift is driven directly by a DC motor, which, in turn, is powered by a battery. Lowering relies on gravity to save energy, and safe, controlled descent is provided by hydraulics.

Each column lift has a control console that can synchronize operation of all four — or even six, if need be — lifts under a vehicle. (The other controls act as slaves.) The proven and secure digital wireless system allows constant communication between the lifting units. The consoles are programmed to exchange data on a dedicated wireless communication channel that is FCC-compliant. The system maintains synchronization by employing digital encoders on each lift to ensure maximum reliability. It compensates for a number of lifting variables including: different power unit efficiencies, different battery power levels, and uneven weight distributions of the vehicle.

The hydraulic circuit is designed to coordinate with the control system to keep the vehicle safely level at all times — as well as for energy efficiency and minimal maintenance. The power unit incorporates a gear pump with pressure-balanced plates for improved efficiency. Under peak load (when lifting the vehicle) only the power unit draws from the battery initially. All lift units put out maximum flow coming out of the stowed position. Fluid free-flows through a solenoid-operated, 2-way, poppet-type holding valve and into the cylinder, raising the load.

The holding valve is not energized during lifting, nor is the proportional cartridge valve that blocks a bypass built into the power unit. However, if the closed-loop control detects some lift units moving faster than others, it will slow the faster ones by gradually opening their proportional valves to bypass some fluid. The control thus balances all the lift speeds.

At the desired lifting height, the control shuts off the pump motor. The check in the holding valve now blocks flow out of the cylinder. Rated at 5 drops/min. maximum, this valve functions as a counterbalance valve would in other hydraulic systems.

A secondary mechanical system automatically backs up the holding valve in case any leakage occurs. Two wedge-block stops (one on each side) engage slotted holes in the post if the lift begins to drift down. These slots are located every 5 in. The wedge blocks slide over the slots while the lift moves up — and are retracted via solenoids when lowering. Again, this arrangement conserves energy during lifting.

During the lowering cycle, the power unit stays off. To start descent, the control opens the holding valve cartridges, energizes the solenoids that retract the mechanical stops, and opens all the proportional valves nearly all the way. (Even with the proportional valves wide open, a valve orifice restricts the descent rate to a comfortable speed.) Again, the control takes over if some lifts descend faster than others and adjusts the proportional valves of the faster lifts to maintain a safe and even lowering speed.

For more information on the Wireless Portable Lift system from Gray Automotive Products Co., St. Joseph, Mich., call (816) 233-6121 or visit www.grayusa.com.