Tough. Brutal. Severe. These are the standard conditions mining equipment designers have to consider. Operation is on rugged terrain in contamination rich environments. Loss of productivity is an expensive reality as operator fatigue sets in over a long shift.

To overcome these issues and the resulting high maintenance costs due to equipment wear and tear, mining suspension systems are now receiving increased scrutiny from owners and operators.

A stable suspension

Mining scalers are used in underground mines to knock down loose aggregate. Scalers are considered mining’s most demanding suspension application because of the tremendous downward pressure exerted when the rock breaks loose and the 90,000-lb. piece of equipment drops to the ground with a force of about 3 Gs. The resulting wear and tear on a scaler and its suspension system (which traditionally consisted of air bags) is so severe that $100,000 in parts maintenance is generally required every year. When the engineering and marketing teams from Breaker Technology Inc. (BTI), Solon, Ohio, set out to develop their all new QS Series Scalers, Figure 1, they knew a stable suspension system would not only extend equipment life and increase operator comfort, it would give them a huge competitive advantage.

Application demands

“The mine face is often so tight that the miner with conventional equipment has to keep clawing with downward pressure to loosen the rock,” notes Bill Aldridge, BTI’s U.S. mining manager. “If he doesn’t release the pressure when the rock lets go, the whole unit comes crashing down, lifting one of the axles one to two feet off the ground. The air bag suspension units just weren’t holding up to these demands. So, for our new scaler, we felt it was extremely important to design and develop a suspension system that would maximize unit stability by fully absorbing the shock.”

BTI’s engineering manager, Brad Toole, noted that operator comfort was a significant issue. “We learned from users that the operator would not generate any more productivity than his body could withstand. As soon as the operator would start to feel fatigued, he would work the machine less. Therefore, one of our goals was to build in more operator comfort to gain higher productivity for our customers.”

The key was to design a platform that would be as stable as possible, a difficult task when dealing with the weight and the balance to hold it.

Further, BTI market studies indicated the need to protect the axles, as competitive units had experienced axle failures. One maintenance specialist noted, “all scalers are designed to break, it is just a matter of how long.” To avoid potential axle breakage, BTI’s design criteria specified that the axles must withstand the force of dropping to the ground from up to two feet in the air on a 90,000-lb. gross weight vehicle, or 45,000-lb. per axle.

Hydraulic accumulators as “gas struts”

Toole first looked at air bag and spring suspension technology and found them lacking. Remembering hydraulic accumulator technology in other applications, Toole checked with Parker’s Hydraulic Accumulator Div. about a possible accumulator suspension solution for the new QS45 Scaler. After looking at the performance requirements, Parker engineers were convinced that their new Accumulator GAStrut technology would work.

The gas strut design, Figure 2, fully integrates cylinder and accumulator technologies into a compact, robust piston design in a virtually leak-free 4000-psi nitrogen gas chamber. The term “gas strut” was applied because the cylinder acts as a strut in the suspension system with pressurized nitrogen gas serving as the active energy shock absorber.

Hydraulic accumulators store energy in the form of pressurized gas. The higher the pressure, the more stored energy in the gas. The stored energy acts like a spring to absorb shock — a perfect fit for mobile equipment with very demanding high force loads.

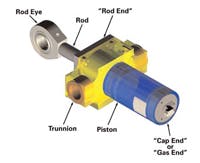

The gas strut differs from traditional accumulators in that it combines the energy storage capability of an accumulator with the functionality of a cylinder. For the BTI application, the cylinder serves as a strut that flexes as a regular suspension unit. The cylinder is attached by a bolted-on trunnion mount that allows for rotation, Figure 3. Inside the cylinder, a piston with a custom designed seal separates the two chambers. Pressurized nitrogen is on the cap end. Nitrogen is used because of its fast response and inert nature. The rod end is open to atmosphere via a filter.

For the BTI QS Series Scaler, the nitrogen gas in each of the four gas struts (two on each axle) is precharged (pressurized) to 4000 psi, five times greater than anything else on the market. Each gas strut has a rating of more than 100,000 lb. While this may sound extreme, it is appropriate for a scaler that experiences 3 Gs as it drops to the ground, or when the vibratory pick scales along mine walls to knock off debris. The reality is that this is a 90,000-lb. mobile vehicle placing three times its weight on the axles. By integrating cylinder and accumulator technology into the four gas struts, the result is a robust, stable suspension design that combines significant load carrying with a high-pressure energy absorption capability.

“Rock and roll” eliminated

“The new gas strut technology,” notes Aldridge, “has eliminated the abuse problem. Our QS45 Scaler is in the heaviest class at 90,000-lb. The stable suspension, coupled with a small footprint, has eliminated the previous ‘rock ’n roll’ operation that causes scalers to come off the ground. In this type of mining operation you only want to set the unit up once. From that position, the miner can go 45° to the left or right. When you do that with a 23,000-lb. boom, you have a lot of extended weight and movement. Scalers with conventional air bag suspensions will come right off the ground when working opposite sides of the mine.”

Report card at 2000+ hours

The increased durability of the suspension system and reduction of shock to the overall machine has already directly translated into lower maintenance costs, reduced downtime, increased equipment life, and significantly greater operator productivity.

“At 2000-plus operating hours,” points out Toole, “the new gas strut suspension has been performing very well. There have been no structural failures on the frame or suspension. Maintenance has been zero, and there have been no oil or nitrogen leaks. Importantly, the operators like the ride. In fact, the machine operators are the best testimonials for the suspension. A big key to the nitrogen suspension is the fact that it is strictly nitrogen. It has proven to provide the fastest reaction time, because there is no oil to displace, as with other systems.”

BTI’s QS45 Scaler

The QS series of mining scalers are showpieces of hydraulics. Their design — chock full of fluid power technology — eliminates the “rock ‘n roll” high maintenance issues that are common with other designs. In addition to the balance and stability of the unit’s gas strut suspension system, the QS45 features the first vibrating pick scaling head. To eliminate the problems associated with mechanical scaling, BTI has combined the action of a pry-bar, pick, and breaker into a single attachment that rotates 360°. Results are production increases of up to 50%, extremely low operating costs, reduced operator fatigue and reduced stress to the carrier.

To an operator, control of the scalers is similar to that of an excavator. The machine features hydraulic pilot controls (joysticks) and two foot pedals for brake and speed control.

Driving, swing and boom, suspension, and vibratory pick are all hydraulic. There are two main loadsensing (auto engine/hydraulic match to demand) pumps (variable displacement/axial-piston) with maximum flow of 2 57.9 gpm (115.8 gpm). Load sensing directional valves are hydraulically pilot operated by the joysticks. A separate pressure compensated pump circuit, totally independent of the two load-sensing pumps, is used for steering and braking. A 66-gal capacity reservoir is standard.

System operating pressures are as follows:

| Main circuit | 5000 psi |

| Hydrostatic propel circuit | 5000 psi |

| Swing circuit | 4270 psi |

| VP pick circuit | 2400 psi |

| Boom hoist circuit | 5000 psi |

| Boom extension circuit | 3000 psi |

| Boom rotation circuit | 3000 psi |

| Tilt circuit | 5000 psi |

| Steering and brake circuit | 3000 psi |

The QS45 features a 45-ft. reach triangular telescopic boom that incorporates three 94,000-psi yield strength tubes, a massive counterweight and highcapacity 269-gal fuel tank. With all of the above combined with the square geometry of the chassis and the 360° continuous swing capability, the unit works with uniform stability in any direction without stabilizers.

In addition to the three-point monitoring, the ergonomically designed operator cab has an 85-dB noise level rating.

As far as electronic controls, again they are designed to mimic that of an excavator, with the exception of the vibratory pick. These smart controls prioritize the hydraulic distribution of power. There is a monitor system, complete machine system tracking, and diagnostics capability — downloadable to a PC.

Generally, scalers are expected to have a four- to six-year life, and seven years of use is considered good. With the accumulator/cylinder gas strut suspension, BTI promotes the following overall benefits: • Longer suspension life before major overhaul. Rubber air bags can be damaged by debris during vehicle operations. The gas strut suspension has a life expectancy several times greater than possible with air bag and spring suspensions. This directly translates to lower maintenance costs and less downtime. • Significant reliability over rubber air bag suspension systems. With an entirely rubber surface, air bags have a much greater chance of gas permeation through the rubber. The steel cylinder acts as a barrier in the QS45 gas strut. It is also combined with a virtually leak-proof seal to ensure that the gas pre-charge is always maintained. • Significantly lower owning and operational cost. Due to less wear and tear, the QS45 scaler is costing 25% less per hour to operate than traditional scalers with air bag suspensions. Fuel consumption is just over 4 gal/hr vs. 8 to 11 gal/hr for competitive units. • Better overall reliability. With the combination of unit balance and stability, reliability for the QS45 is currently running at 90%, comparing favorably with competitive scalers. • 50% productivity improvement due to lower vibration and noise levels and less operator fatigue, and • A smaller, more compact machine. Because the suspension is more compact, the overall height of the unit decreased. This solved a big issue for transportation — both on the highway and when entering the workplace.

In the QS45 suspension, the cylinder OD is 7.5-in. with a 30-in. length when extended. This allows for a 3-in. clearance from the top of the strut to the undercarriage. Cylinder length was limited due to space constraints, so a remote auxiliary gas bottle was used to ensure sufficient nitrogen gas capacity for the vehicle’s initial loading.

Additional applications

Further potential exists for the GAStrut in other mining applications that require self-contained dampened suspension units such as coal mining shuttle cars. Here, the gas strut could be used as a type of limited suspension, improving operator comfort and reducing stress on the frame and undercarriage to increase unit life.

“Shuttle cars generally last one to three years before serious maintenance is needed,” says Mike Schubert, business development manager at Parker’s Hydraulic Accumulator Div. “By the second maintenance period, a complete overhaul and rebuild is generally required. A gas strut suspension would increase the time period between maintenance and rebuild.”

There is also potential for using the combined cylinder/accumulator technology for track tensioning in bulldozers, excavators, and tractors. There is a specific tension that needs to be maintained on the tracks of these vehicles. If the tension is not high enough, the tracks will fall off. If it is too great, the tracks will snap. Today, this task is generally handled by large springs, which can be difficult to fit within the track widths. A single unit cylinder/accumulator might be a perfect fit.

“Springs can be compressed, or extended, to the point of wearing out or where their tensile strength is changed,” continued Schubert. “With nitrogen, there is no elasticity point. It continues to compress with no change in its physical properties. So, as long as you don’t exceed the working design of the accumulator cylinder, there is greater flexibility in how far the nitrogen gas can be compressed. The benefits are longer life because accumulators can be recharged as necessary, and they allow for the design of smaller, more compact suspensions than possible with springs or air bags.”

Semi-active and active suspensions

The GAStrut is an example of a passive suspension, which has been the traditional standard on construction and mining vehicles. Passive suspensions simply react to the input they receive — namely changes in terrain. Typically, these are leaf springs and strut arrangements, and double coils that attempt to dampen the shocks from terrain changes. Once set, these systems cannot be adjusted. Some designers add multiple dampening or spring rates to suspensions. This can be a cost effective way to vary the spring rate based on the loading the vehicle encounters. Some mining suspensions incorporate air bags to absorb the shock loading. However, these have a short life.

“The other type of suspension is an active suspension, which holds promise for mining applications, due to its many operational benefits,” explains Schubert. “Active suspensions are designed to resist the input received by countering the input force with a second force in the opposite direction. They have been available on automobiles for years, but are rarely, if ever seen on construction and mining vehicles. Yet the benefits from a properly designed active and stable suspension are higher ground speeds, better cornering, reduced rollover, greater operator comfort, increased productivity and lower maintenance costs.”

The new semi-active and active accumulator/ strut suspensions in development will use sensors on the suspension with an auxiliary power unit to measure the impact of ground terrain. Algorithms in the sensors will tell the accumulator valve to open by a given percent to allow the correct fluid discharge to counteract the force being placed on the suspension by the ground. This “active” approach to mining suspensions can reduce the shock amplitude by as much as 66%.

For more information, call BTI at (708) 205-6060 or visit www.rockbreaker.com.

For more informtion from Parker's Accumulator Div., call (815) 621-7024 or click here.