The city of Denver prides itself on being one of the greenest in the nation. Its fleet of more than 2800 vehicles includes nearly 150 hybrid cars.

Its latest addition, a Peterbilt Model 320 refuse collection truck, reflects the city’s commitment to green energy and fuel-saving operations. Sporting an eye-catching custom Viper Green paint scheme, the truck is equipped with a Hydraulic Launch Assist system provided by Eaton’s Hydraulics Group, which boosts fuel efficiency while reducing vehicle maintenance costs and improving overall collection efficiency.

How this truck, one of only 12 in the country, came to work in Denver illustrates how public-private cooperation is advancing the “green” technologies slated for the future. The story begins in 2006 in Houston, where the Houston Advanced Research Center (HARC) was awarded a grant to support installation of Eaton’s Hydraulic Launch Assist (HLA) systems on a fleet of 12 refuse collection trucks as a practical demonstration of the technology.

“Eaton has been developing HLA technology for a while,” notes Robert Golin, business lead at Eaton’s Hydraulics Group, Eden Prairie, Minn., “starting with a Ford Super-Duty pickup we built in 1999 for an EPA demonstration project. We teamed with Peterbilt for the HARC effort because of their experience with heavyduty chassis design and the attractive duty cycle that refuse trucks represent. There’s a big difference between a pickup and a refuse truck, after all.”

Hybrid basics

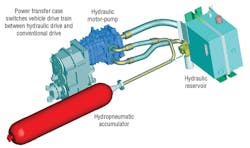

The fundamental idea behind Eaton’s HLA system is to capture and store energy that otherwise would be wasted during the vehicle’s normal operation, then use that energy when needed to reduce fuel consumption. This typically takes the form of regenerative braking, in which the hybrid system captures and stores the vehicle’s kinetic energy, rather than dissipating it as friction.

During deceleration, the HLA system stores energy by pressurizing fluid in an accumulator. Storing this energy means it is not dissipated as heat through the brake system and, ultimately, wasted. The stored energy then is fed back to the vehicle during acceleration to reduce the amount of fuel needed to get the truck moving back up to road speed.

A hybrid system can be configured with either a series geometry, which means it replaces all or parts of the mechanical drive train, or a parallel geometry, meaning it operates in tandem with the mechanical drive train. HLA is a parallel system.

HARC demonstration trucks

Eaton supplied 12 HLA systems to Peterbilt for the HARC-funded demonstration trucks. Of these, 11 were placed in operation with municipal and private operators in Houston, Dallas, and other Texas cities.

“These trucks are all equipped with anti-lock brake systems (ABS) in addition to the HLA system,” Golin says. “Before we were ready to release the prototype system for commercial manufacture, we needed to know how the ABS and the HLA system interface performed under winter conditions, particularly on ice and in heavy snow.

“Obviously, we could not get those answers in Texas, so we began looking for a place with severe winters that also might be interested in being a hybrid technology pioneer. Denver officials had seen the prototypes at the 2006 Hybrid Truck Users Forum and CALSTART Conference in San Diego, so they were receptive when approached by the local Peterbilt representative about obtaining one of the HLA-equipped vehicles.

“Actually, they were due to replace a vehicle in 2008, so it was just a question of whether it would be a conventional diesel-only, or a hybrid. Given the city’s commitment to green technologies, I have to assume it was a pretty easy decision,” he says.

“Denver has the additional advantage of being the Mile High City, so we got to test HLA performance during a very cold, snowy winter at high altitude. That made it doubly attractive to us.”

More big benefits

As a typical Denver refuse truck, the Peterbilt Model 320 vehicle equipped with the HLA system supplied to the city averages 8400 miles per year of difficult, stop-and-go driving. City officials report that it has averaged 2.875 mpg, a 25% improvement over the 2.3 mpg average of the city’s conventional trucks.

Although that may not sound like much, it adds up to about 1600 gal of bio-diesel fuel saved per year. It also means that 1600 gal worth of NOX, particulates, and COX were not injected into Denver’s air.

“Although percentage improvement varies with duty cycle, there are three main benefits to the HLA system: fuel savings, brake savings, and productivity increase,” Golin adds. “Through continuous truck testing in the field, the engineering team found that brakes lasted much longer. A conventional truck typically needs its brakes replaced three or four times a year, and a brake job on one of these trucks typically costs $2000 or more. On trucks equipped with the HLA system, the brakes often lasted a year or longer. We don’t have enough experience in Denver to say conclusively that we’re getting that kind of brake life there, but city officials have said publicly that they anticipate longer brake life from the hybrid truck.”

Trucks equipped with the HLA system also decelerate smoothly because of the cushioning effect of the hydraulic system. This feature minimizes deceleration-related wear and tear on all truck components. “That’s important in an application in which drivers are known to follow the philosophy of keeping either the accelerator or the brake fully depressed at all times,” Golin says.

Another benefit of HLA technology is more rapid acceleration because the large amount of energy the system stores is available to overcome inertia without using additional fuel. That means operators can trim seconds off the average duty cycle.

“One of these trucks typically starts and stops up to 1200 times a day,” Golin notes. “If the HLA technology can trim a couple of seconds off each of those cycles — and that’s conservative — it means the same truck can make more stops in a workday. More stops per truck could also mean the fleet can handle more business without increasing the fleet size, and in a municipal setting like Denver that can mean hundreds of thousands of dollars are saved every year.”

Finally, the Denver testing proved that the ABS-HLA system interface worked as designed under demanding conditions. “This was a severe winter in Denver,” Golin says, “and it gave us a really good test of the brakes, the HLA system, and the interface that coordinates their operation. The whole system performed up to expectations on ice, snow, wet pavement, and all the combinations of those conditions you would expect during a Denver winter.”

The next step

“Probably the biggest challenge in the past year was the severity of refuse duty cycles. However, with successful reliability growth over the past months, the HLA system will be ready in September to go into production.”

Ultimately, the HLA system proved to be both durable and efficient. It will join Eaton’s light-duty and medium- duty hybrids as a commercially available product of the company’s Spencer, Iowa, manufacturing plant in September 2009.

And yes, there is a very good chance some of those systems will end up on other streets in the coming years, so watch for a big green truck on a street near you.

Click here for more information on Eaton's hydraulics hybrid power technology.