Compressed air is a safe, clean, and convenient form of energy. But unregulated or improper pressure settings can result in increased compressed air demand, resulting in higher energy consumption. Excessive pressure can also increase equipment wear, resulting in higher maintenance costs and shorter tool life. A rule of thumb states that every 2-psig increase in operating pressure adds an additional 1% to compressed air energy cost.

Perhaps more important is having clean, dry air. Clean air prevents equipment malfunctions and premature component failures. Filters are an essential component of any compressed air system to remove all the dirt drawn in from the atmosphere by the compressor. Some filters can remove a small portion of moisture from the air, but they should not be used as a substitute for air dryers.

However, the trend in most new systems is to use unlubricated air and components that are lubricated for life — primarily valves and cylinders. Lubricators are beyond the scope of this article, but detailed information on lubricators can be found by clicking here.

Particulate filters

Contaminant particles in compressed air usually are measured in micrometers (µm), or 0.000039 of an inch. Filters are rated according to the minimum particle size that their elements will trap. Although filters rated 40 to 60 µm are adequate for protecting most industrial applications, many point-of-use filters are rated at 5 µm.

Finer ratings increase the pressure drop through the filter, which equates to higher energy cost to compress the air. In addition, finer filters clog more rapidly, also increasing pressure drop. In other words, although filters finer than necessary do no harm to downstream components, they will have a negative impact on air system operating cost.

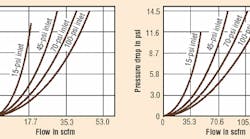

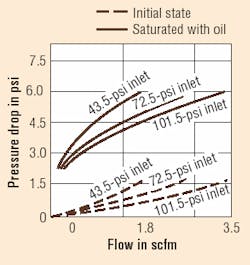

Many filter manufacturers define the expected pressure loss and dirt holding capacity using curves related to pressure and flow. Therefore, particulate filters should be selected based on acceptable pressure drop and pipe connection size. A typical pressure drop through such filters would be between 1 and 5 psig. A filter with larger body size will produce less initial pressure loss and provide longer operating life than a smaller size filter with the same removal ratings. The charts in Figure 1 compare pressure drop through several particulate filters that all have identical 5-µm removal capacity.

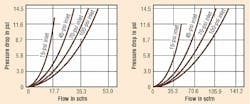

Most filters can remove condensed water, typically via a form of cyclone separator at their inlet end, Figure 2. The water-removal efficiency of such filters depends on the incoming air velocity. Therefore, these filters must be matched to the intended air flow, rather than acceptable pressure drop.

If the filter is intended to remove moisture, an integral automatic float-type drain should be provided to periodically remove accumulated liquids from the filter bowl. Generally, such filters have transparent polycarbonate bowls to allow easy visual inspection of the liquid level.

Coalescing filters

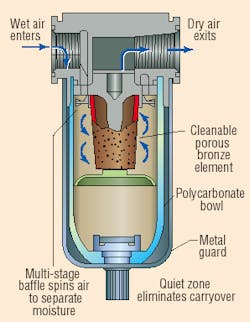

Most oil entrained in a compressed air stream, as well as some of the condensed water, will be in the form of mists or aerosols that can pass through the openings in standard airline filters. Aerosol carry-over through such filters is commonly stated as parts per million (ppm) of oil vs. air by weight and will range from 1 to as little as 0.01 ppm. Coalescing-type filters, Figure 3, can remove these contaminants.

Coalescing filters are often rated to remove aerosols that are substantially smaller than the nominal size of the smallest solid particle that would be captured. Some models offer dual-stage filtration; the first removes solid particles to protect the coalescing element in the second stage.

Because all coalescing filters create a greater restriction to the air flow, pressure losses will be higher than those of simple particulate filters. Coalescing filters have an initial (or dry) pressure drop and a working (or saturated) pressure drop, both based on pressure and flow rate. The effective removal efficiency of such filters depends greatly on the air velocity passing through the filter assembly. A coalescing filter rated at 0.1 ppm will typically have a clean, wetted pressure drop of 2 to 5 psig, while a high-efficiency filter rated at 0.01 ppm can cause as much as 10-psig drop once it becomes wet or fully saturated during service, Figure 4.

Pressure regulators

Once a minimum suitable operating pressure has been determined, it is essential to supply the air at a constant pressure, regardless of upstream flow and pressure fluctuations. Thus, the proper regulator or pressure-reducing valve should be installed in the air line. Regulators reduce supply pressure to that required for efficient operation of downstream pneumatic equipment. A filter to protect the regulator's internal passages from damage should always be installed upstream from it.

The simplest type of regulator uses an unbalanced-poppet-style valve. This design incorporates an adjustment spring and is non-relieving. Turning an adjustment screw compresses the spring, which forces the diaphragm to move, thus pushing a poppet to uncover an orifice. As pressure rises downstream, it acts on the underside of a diaphragm, balancing against the force of the spring. The poppet throttles the orifice opening to restrict flow — and produce the desired downstream pressure. A spring under the poppet ensures that the valve closes completely when no flow exists. This is the least expensive type regulator.

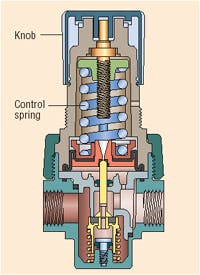

Larger, more expensive regulators, Figure 5, incorporate a separate diaphragm chamber, which has an aspirator tube exposed to the output pressure. Segregating the diaphragm from the main air flow minimizes its abrasive effects and extends the life of the valve. As flow through this regulator increases, the aspirator tube creates a slightly lower pressure in the diaphragm chamber. The diaphragm deflects downward and opens the orifice without significantly reducing the output pressure. The effect is the same as increasing the adjustment setting. Thus, this style regulator has minimal droop (output pressure decay) as supply pressure varies.

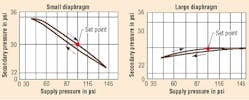

Figure 6 compares how that variance occurs with a small and a large diaphragm. The larger diaphragms in these regulators improve response and sensitivity. As discharge flow through the regulator is increased over its entire range, output pressure droops. Therefore, it is important to set the regulator's desired output pressure under normal flow conditions.

Another type of regulator incorporates a balanced poppet, but otherwise has the same general construction as the separate diaphragm version. It has a significantly larger orifice to allow for greater air flow. To maintain good stability, the poppet is pressure-balanced. The effects of output pressure fluctuations cancel out, which improves sensitivity and response and reduces droop. Finally, precision regulators often employ several isolated diaphragms acting against flapper valves and nozzles in a balancing principle and are normally manufactured in limited flow capacities with smaller connection ports.

Selecting the best type of regulator for a specific application first requires a choice among these styles. Mini-regulators are commonly the direct-acting, nonrelieving type, while most standard regulators fall within the self-relieving, separate-diaphragm-chamber style. The next consideration becomes primary (unregulated supply) pressure versus desired secondary (output) pressure.

Finally, desired air flow rate must be determined. Adjusting screws are normally offered in two styles: tamper resistant, locking Tee type or push-lock, plastic knob type. The first is best when a fixed operating pressure will be set once and left alone. The adjustable knob style (quite common on modular units) is the correct choice for general use, where the operating pressure can be easily adjusted without tools.

Regulators also are defined by body size (orifice flow rating) and connection size. Although several models may appear to be acceptable for any given air flow and pressure, a larger body size regulator will produce better setting sensitivity and less droop than a smaller body model under the same set of operating conditions. An output pressure gauge is essential, although many manufacturers frequently offer it only as an option. Mounting brackets are another useful option.

Modular or combination units

Manufacturers frequently preassemble filters and regulators (and lubricators, when required) to form combination units. They are packaged together as common body sizes with common connection port sizes. Interconnections may be via threaded nipples or modular face connectors. The modular connectors allow easy removal of components for servicing or cleaning.

In addition, some manufacturers combine filters and regulators into single assemblies where the filter head becomes the regulator body. The components share common inlet and outlet connections, which makes the assembly very compact.