This file type includes high resolution graphics and schematics when applicable.

Most cylinder manufacturers have developed a variety of methods to enhance the operation of their cylinder. Primary targets for improvement have been in the areas of deceleration, reduction of vibration (caused by metal-to-metal bounce), and the reduction of noise caused by vibration.

End-of-stroke cushioning

One of the primary objectives of cylinder operations is to decelerate a cylinder's piston rod at the end of stroke. There are two distinct camps when it comes to deceleration. The first involves a mechanism external to the body of the cylinder known as external cushioning. External cushioning incorporates a shock absorber type mechanism that helps to decelerate the load. The drawback to external cushioning is that it increases the footprint of the cylinder, adds weight, and involves additional moving parts.

The second mechanism is known as internal cushioning. This incorporates a design that is internal to the cylinder — so it operates within the cylinder footprint and tends to be simpler in function.

First, it is necessary to understand why we need to decelerate the piston, and the results that take place when the piston is not slowed sufficiently at its end of stroke.

The importance of deceleration

Conventionally designed cylinders have a metal piston and metal end caps. Piston deceleration is required as it enters end-of-stroke in order to avoid hard metal-to-metal contact with the end caps. Metal-to-metal contact manifests itself in three ways:

- wear on the contacting surfaces

- vibration or bouncing caused by the bouncing of the surfaces against each other, and

- noise, the product of vibration.

Wear is something we always want to avoid. Some noise is natural in any moving device, but it should be a goal to lessen component wear whenever possible. Vibration, or bouncing, at end of stroke means the piston isn't re-ally stopped; it is still moving. Depending on the severity of contact, a piston may bounce (vibrate) 3 to 4 times. Noise is the result of this vibration. In the workplace, this noise can be at best irritating; at its worst, noise can create an un-pleasant and dangerous environment, especially if it exceeds OSHA requirements.

Conventional deceleration

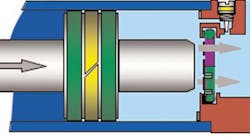

As the piston nears its end of stroke, it must be decelerated before reaching end of travel. The most accepted method for deceleration is air cushioning. Air cushioning is the result of the piston rod entering the cylinder's end cap. The air in the cap is squeezed or compressed, resulting in a negative force acting upon the piston.

Conventional air cylinders rely 100% on the non-linear air cushion to decelerate the load by compressing the gas in the cylinder's controlled volume at the end of stroke. As an air cylinder is traversing through the stroke, a constant velocity is achieved by controlling the exhaust flow out of the cylinder. This exhaust flows freely out of the cylinder through the center of the end cap downstream to the flow control. As the cylinder nears the end of stroke, the cushion spear of the sleeve enters the cushion seal, eliminating the free flowing exhaust path. The controlled volume now decreases without an exhaust path, and the gas compresses. Exhaust is then metered out through the cushion needle, for desired cushion performance.

Deceleration formulas

To decelerate a cylinder, a negative force must be generated.

F — friction = ma

The objective is to decelerate the cylinder to a very low velocity before end of stroke metal-to-metal impact or to absorb the cylinder's momentum before dissipating the resultant energy with end of stroke metal-to-metal impact.

A typical air cushion provides an elevated backpressure, resulting in a negative force component to decelerate the load. Typically, before the cylinder reaches the air cushion, the actuator achieves a constant velocity by achieving equilibrium between the net driving force and the frictional forces.

F— friction = ma = 0

When the cylinder enters the cushion, an elevated backpres-sure is achieved by compressing the controlled volume of air in that chamber. This elevated back-pressure provides a negative force component to decelerate the load.

(-F) —friction = ma

In daily life, we decelerate everyday to avoid hard contact, and we also meter our deceleration. Imagine pulling your vehicle into a parking space. As you pull up to the curb, you decelerate to avoid hard contact. You use your foot brake to meter how dramatically you slow down. If you don't slow down enough, hard contact is experienced. If your deceleration is slow, it takes too long to bring your vehicle to a stop. It is all a trade off. Not enough deceleration means a hard stop; too much deceleration means it takes too long to stop.

Adjustable air cushion

To control, or meter, the volume of air being released during the compression phase at end of stroke, an adjustable cushion is used (see illustration on page 46). This typically consists of a threaded needle screw that adjusts into an orifice in the cylinder end cap. By adjusting the screw further into the orifice, the amount of air that can escape in a given time is reduced. Slowing the exhaust of air creates back-pressure, slowing the piston as it enters the end cap. The slower the air exhausts, the more dramatic the deceleration.

The objective of cylinder deceleration is:

- to avoid potentially damaging metal-to-metal contact

- to reduce vibration, and

- to reduce noise.

With the adjustable cushion, all three objectives can be accomplished ... to a point.

A designer may be inclined to say, "Just increase the time it takes to slow down the piston to the extent that we avoid hard contact, thus eliminating bounce, and bring in the piston so slowly we don't hear any contact." While that will work, how long does this take? Taking longer to decelerate and stop the piston-translates to a drastically increased cycle time, which will result in reduced efficiency and profits.

Redefining the cushion

What is the best way to avoid hard contact (that results in wear, bouncing, and noise), while at the same time making sure cycle times are reasonable? By redesigning the cushion seal and its attachment to the piston, deceleration problems can not only be remedied, but the redesigned cushion seal can provide additional benefits to cylinder operation.

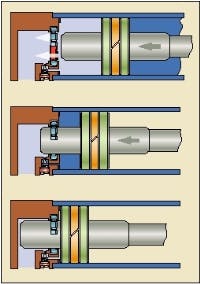

Cushion seals that extend beyond the face of the piston have proven very effective in cylinder deceleration and at the same time increase cylinder performance. When the piston nears end of stroke, the rubber seal contacts the cylinder cap rather than the metal face of the piston. Hard metal-to-metal contact is avoided. This eliminates the wear caused by metal-to-metal contact, extending the life of the cylinder.

What about vibration caused by bounce? These extended seals, usually comprised of nitrile-based rubber pressed-fit into a machined grove on the piston, absorb 80% of the energy as the cylinder completes its stroke. This reduces the pneumatic bounce, a large amplitude, high frequency, end-of-stroke impact vibration that is destructive to the cylinder and to the surrounding equipment. Eliminating it extends the life expectancy of equipment.

Higher cycle rates

In addition to reducing noise caused by vibration, there is further benefit: with the seal absorbing 80% of the energy, the desired cushion orifice can be much larger — allowing the cylinder to travel through the cushion in 1 /4 the time of a conventionally cushioned cylinder. Plus, the extended type seal piston accelerates out of cushion at a higher rate.

This is accomplished in two ways. First, the cushion orifice can be much larger for the desired end of stroke performance, and this larger orifice provides a larger bleed orifice to allow air into the cylinder at a faster rate while exiting the air cushion. Second, the seal acts as a compressed spring and provides an initial force equivalent to 80 psi to push or accelerate the cylinder into motion.

This reduces in-cushion time by approximately 75%.

This article is adapted from the white paper, Improving Air Cylinder Deceleration, published by Norgren, Littleton, Colo. Click here to download a copy.

This file type includes high resolution graphics and schematics when applicable.