Going to an amusement park excites all the senses. You smell the popcorn or cotton candy a family is enjoying as you enter the line to a roller coaster. You see bright colors all around you as you walk up the ramp. You taste the sweet soda you have to gulp down as you enter the cue line before boarding the ride. Your feet feel the rumble of the wooden floor as the coaster roars into the loading area. Finally, you hear the familiar "pshhht" as the pneumatic cylinders open the gates that allow you to climb into the coaster.

For roller coasters, pneumatics is used primarily in safety systems. In the newer coasters, pneumatic actuators open gates that keep riders-to-be out of the boarding area until the arriving train has come to a complete stop. Pneumatics is also used in many restraint systems to ensure that you remain in the car as the coaster goes through just about any maneuver imaginable. When the ride is nearly over, it's usually pneumatic brakes that bring the train to a complete stop.

Sometimes, though, pneumatics gets the job done where nothing else can. Because pneumatic actuators can work in the complete absence of electricity, stand up to the potentially damaging effects of water, and pose no threat to water cleanliness, they are widely used in aquatic themed thrill rides and other attractions.

Pneumatics is also known for rapid cycling, which is why it is used so extensively in factory automation. In theme park attractions, pneumatic actuators are called on to cycle rapidly — hundreds or thousands of times a day under a variety of load conditions.

Another advantage of pneumatics is that when properly designed, drives can take advantage of the compressibility of air to provide cushioning. This cushioning can go well beyond the end-of-stroke cushioning most often found in industrial pneumatics. By controlling the opening and closing of valves, the compressibility of air can be used to smooth out accelerations and decelerations of motion profiles.

Following are descriptions of three examples that demonstrate these principles. What they share is the reliability inherent to pneumatics that produces trouble-free, long service life.

In deep water

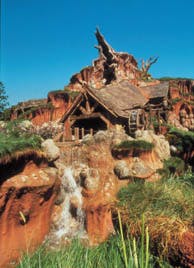

When guests board the Splash Mountain ride at Disneyland or Disney World's Magic Kingdom, they climb into a floating fiberglass log with unseen wheels mounted underneath. This configuration allows the log to float through a winding circuit of water-filled channels, and also scale a hill and roll down the other side.

The longest of these drops plunges guests 52.5 ft at 47°. As the log approaches the bottom, it reaches speeds of 40 mph, so deceleration must be accomplished quickly and safely, before continuing on its meandering journey through a labyrinth of channels.

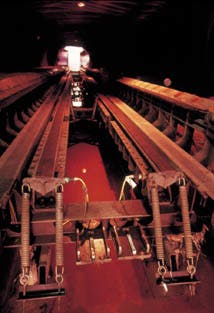

The key to slowing down the log is a pair of 40-ft brake pads at the bottom of the drop. The brake pads are completely under water, but pneumatics provides an ideal solution. Each of the two brake pads is actuated by eight air bags.

Each bag is essentially a length of high-pressure hose that has been sealed at both ends, with a valve located in the middle. Pressurized air entering the bags causes them to expand and push upward on the pads. The hose is rated for 200-psi service, but operating pressure of the system is only 60 to 90 psi. When actuated, the pads contact the underside of the log, and friction gradually slows the log down to the desired speed.

The bags have no seals and produce no sliding motion that would cause component wear — which is especially important in this underwater application. The large surface area of the bags generates tremendous lifting force that is uniformly distributed over the length of the rails. Had multiple conventional cylinders been used to actuate the pads, forces would have been concentrated at the attachment point of each piston rod. This could have caused a bumpy ride as the log passed over each cylinder.

Rapid, repetitive motion

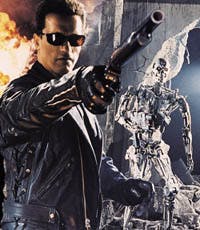

A much different application of pneumatics is found at Universal Studios Florida's Terminator 2: 3D. Among a myriad of other impressive effects, the attraction features a 12-minute sequel to Terminator 2: Judgement Day presented as a three-dimensional motion picture on three 23 x 50 ft screens, oriented 60° from each other. This makes viewers feel that they are in the movie — not just watching it.

In the attraction's most amazing effect, the movie shows the title character, played by Arnold Schwarzenegger, riding a motorcycle. Suddenly, Schwarzenegger starts riding directly toward the camera. And don't forget, because the movie is three dimensional, it appears to the audience as if he is riding directly toward them. So with the surround screens, this really gives the impression that the audience is right in the middle of all the action.

Just as the bike appears to reach the stage, an explosion occurs right in front of the screen. Suddenly, a real actor is riding a real motorcycle on stage. Even when the audience views this attraction several times, they can't see how a 1500-lb Harley Davidson can instantly appear on stage. And it doesn't just appear on stage. When guests first see it, it's already moving at about the same speed as the one they saw in the movie.

Pneumatics, of course, is the key to this effect. What guests don't realize is that the screen they're watching is not stationary. As they view the action-packed film, explosions occur in the movie and on the live stage. They appear to occur at random, but actually are carefully orchestrated.

When the on-stage explosion occur just in front of the screen, the pyrotechnic display obscures the view of the screen for about second. This is just enough time for a pneumatic rodless cylinder to pull the screen up out of view. With the first screen now hidden, the movie is projected on a second screen, which is positioned just behind the first one. This second screen has a narrow vertical slit down its center. When the next explosion occurs, another pneumatic cylinder pulls the left and right halves of the screen apart.

Before all this happens, a stunt actor mounts the Harley and drives toward the screen from backstage. As the bike approaches the screen, a switch is tripped to set off the on-stage explosion and raise the first screen. Simultaneously, the rodless cylinder opens the slit screen, and the bike and stunt actor plunge onto the stage with engine roaring.

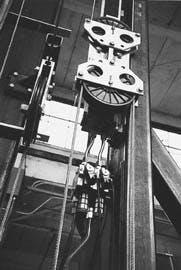

A key design challenge was achieving the exceptionally high speed for this application. Pneumatic cylinders are normally designed for speeds to about 60 in./minute, but to lift the first movie screen 6.5 ft in less than a second requires a stroke speed of 42 in./sec.

To achieve this high speed, a 3-port, 2-position valve is mounted at each end of the cylinder to simultaneously control pressurization and exhaust. To ensure that an ample supply of compressed air is available at each end of the cylinder, four air tanks (two at each end) act as accumulators to store compressed air energy. Locating these tanks near each valve essentially eliminates pressure drop and line losses.

Air smooths motion transitions

Most motion bases, whether used in flight simulators or theme park attractions, use stiff, servo-controlled hydraulics for precise control of motion. But the Cyber Air Base, designed by Brad Engstrand, chairman of Virtogo Inc., Chicago, uses a set of discrete air valves to produce, in effect, proportional motion control

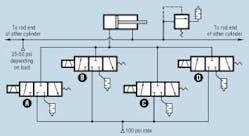

In the Cyber Air Base, compressed air flows to the cap end of each cylinder through four directional control valves piped in parallel. This is a six-axis motion base, so there are six cylinders and 24 valves. These are not proportional valves; instead, they are on/off type poppet valves. Response is typically under 50 msec. The valves go from fully closed to fully open in less than 5 msec, so most of the response time involves waiting for enough air to flow into the cylinders to build adequate pressure. When a valve opens, the compliance of air acts as a cushion to accelerate the load, instead of producing the jerky motion of a hydraulic on/off valve. This type of motion is similar to that produced by a soft-shift hydraulic valve.

More importantly, each of the four valves is a different size. So to accelerate rapidly, all four valves shift to connect the cap end of the cylinder to pressure. When lower acceleration is needed, any combination of one, two, or three valves open. Flow is regulated by controlling which valves are open, which is determined by control software. For sake of discussion, say valves A, B, C, and D can pass 1, 2, 3, and 6 scfm, respectively. Therefore, any flow rate can be achieved in increments of one anywhere between 0 and 12 scfm. Opening valves A, C, and D produces flow of 10 scfm; opening B and D produces 8 scfm. Compliance is important because it creates transitions that smooth out motion as valves shift.

Brad Engstrand was chairman of Virtogo Inc., Chicago, which manufactured the Cyber Air Base, when this article was opriginally published. He is now president of Motion Controls LLC, Hartford, Wis., a manufacturer of pneumatic cylinders and the InSight positioning system using QVLA sensors.