Pneumatic systems are often used when machines require precise control of actuation, damping, or displacement. A new line of Accurate Force Pneumatic products and systems from Airpot Corp., Norwalk, Conn., is intended to produce the accuracy and low friction needed when tensioning wire and filament; positioning and manipulating optics; measuring creep, weight, tensile strength; and more.

Valves and other pneumatic components, in conjunction with Airpot’s glass cylinder lining and graphite piston, give designers force and motion control levels unobtainable by other pneumatic means, according to Airpot.

Eliminating stick-slip operation

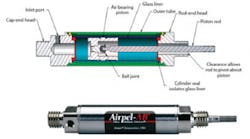

Unlike conventional single-acting air cylinders, Airpot’s Airpel-AB cylinders have no physical piston or rod seals. Instead, the piston and rod use the compressed air as an air bearing by allowing a controlled amount of air to leak past them and prevent physical contact. Eliminating the physical contact likewise eliminates the stick-slip operation that is inherent to physical seals.

The Airpel-AB cylinders also use a ball joint to mount the piston rod to the piston, making the cylinder self aligning. Airpel-AB cylinders are available in four standard bores from 9.3 to 32.5 mm and stock strokes from 10 to 300 mm (specials from 1mm to 1 m). They are designed to operate with clean, dry air at pressures up to 0.7 MPa.

Near-zero friction actuation is possible, allowing for ultra precise measurement, application of minute forces, and sub-micron control of linear displacement. The cylinders are intended for applications where accuracy is critical, including micro machining and polishing and grinding equipment. Other targeted applications include semiconductor, electronics, medical devices, metrology, test and measurement, and laboratory diagnostic equipment.

The cylinders are intended for applications where force accuracy or minimal friction is critical, including linear motor z-axis counterbalancing and generating precise forces for grinding, micro-machining, deburring, polishing, and cutting.

Airpot’s other air cylinder lines (standard Airpel and Airpel-PL) use pistons that are not air bearing but have very low friction. In addition, precision piston and cylinder sets make it possible to precisely dispense small volumes of air in pumping and flow applications. They can also be used for specialized linear bearing requirements.

For details, contact Tom Lee at [email protected], call (203) 846-2021, or visit www.airpot.com.

Related Articles

Pressure gauges and flow meters keep an eye on system performance

How to boost energy efficiency in industrial machines