Processing line cycling improperly

In the food and pharmaceutical processing industries, leaking actuators can contaminate products and cause expensive recalls. Even if food-grade hydraulic oil is used, it can affect the taste and even make some consumers sick. (Unfortunately, I’ve had this experience personally.)

A common practice with cylinders in these industries is to install an additional rod cap with a seal onto the standard rod cap. In effect, it makes two rod seals in series with a clear plastic tube draining the area between the two caps. If the main seal started to leak, the clear plastic tubing would drain the leaking oil back to tank before it had a chance to possibly leak through the second cap’s rod seal. Drain lines like these are one of the rare examples of terminating drain lines above the fluid level. Maintenance personnel routinely check these drain tubes for signs of oil leakage. If a cylinder’s drain tube showed any leakage, the technician would schedule the cylinder replacement on the next shutdown.

A problem developed with one of the cylinders used on a toothpaste line. If the line stopped for more than two or three minutes, the cylinder would drift, retract, and trip a fault sensor. The first two products were removed from the line, a cycle rest button was pressed, and the auto cycle commanded the cylinder to advance. It would lunge forward as if the meter-out flow control bypass check was stuck open. If the cylinder was manually cycled 10 to 15 times, then switched to the auto cycle, it seemed to work fine until the line stopped again.

The flow control and directional valve were replaced. Because the cylinder showed no signs of leakage, personnel verified that the piston seals were not internally leaking and reinstalled it.

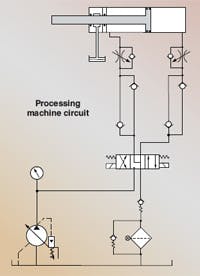

The circuit shown had been in service several years and worked well. The cylinder is located on the first floor approximately 50 to 60 ft above the hydraulic power unit located in the basement. The unusual dual line with checks was installed to ensure fresh, clean oil migrated to the cylinders and that oil returned to tank. The directional valve was mounted about 10 ft below the cylinder.

Any thoughts on what the problem might be?

Solution to July's clamping system problem

As a rule, when a closed-loop hydraulic control system goes to a commanded position and tends to oscillate, gain is usually set too high and must be adjusted to a lower value, or the PID loop needs to be tuned. However, these adjustments didn’t solve the problem.

What was found causing the problem was that the ball screw backlash adjustment was excessively loose. When the hydraulic system was commanded to correct the overshoot, the hydraulic motor was turning in the opposite direction but the ball screw didn’t respond quickly. When it did move, it lunged past the set point. A mechanical adjustment to reduce backlash in the ball screw solved the problem, which, of course, had not been caused by the hydraulic or electrical control system.

Robert J. Sheaf Jr., is the founder of Certified Fluid Consultants (CFC) and President of CFC-Solar Inc. CFC-Solar provides technical training, consulting, and field services to any industry using fluid power technology. Visit www.cfcsolar.com for more information.