Many mobile equipment operators in the construction, forestry, mining and transportation industries across the northern U.S. and Canada continue to change out hydraulic fluids for summer and winter use. However, recent evaluations have shown that switching to a single multigrade fluid for year-round operations can improve fuel efficiency for greater cost savings while maintaining - and even improving - lubrication protection.

High and low temperature impact on viscosity

When it comes to hydraulic fluids, overall pump efficiency relies on obtaining the ideal balance between hydro-mechanical efficiency and volumetric efficiency. More simply stated: the viscosity of the hydraulic fluid must be thin enough for the hydraulic pump to start easily, especially at low temperatures, and to prevent it from working too hard (mechanical efficiency), but thick enough to prevent internal pump leakage, loss of pressure, and effective lubrication (volumetric efficiency).

Excessive viscosity at low temperatures can result in reduced mechanical efficiency of the hydraulic system and, in more extreme situations, to lubricant starvation and cavitation. During lubrication starvation, the loss of the thin lubricant film protecting parts creates high contact temperature, excessive wear, and ultimately results in pump seizure. Cavitation is created due to excessive pressure drop at the pump inlet. This eventually leads to metal fatigue and spalling, generating abrasive metal particles in the fluid and reducing pump life.

If viscosity is too low when oil temperatures increase, volumetric efficiency drops due to increased internal leakage. Also, if the fluid is too thin, moving parts are not properly protected - resulting in metal-to-metal contact, overheating, parts wear, and eventual pump seizure.

Thus, if viscosity is too high or too low, the resulting wear in parts leads to an additional decline in volumetric efficiency. As a result, the hydraulic pump must work harder to produce the required flow to hydraulic actuators. The engine must, therefore, burn more fuel to produce the desired amount of hydraulic work. Higher fuel consumption equals higher costs. It also equals greater carbon dioxide (CO2) emissions, which are damaging to the environment. An ideal hydraulic fluid self-adjusts to the widest possible changes in temperature, ensuring a smooth startup as well as efficient peak-temperature operation.

Multigrade hydraulic fluids are formulated with high viscosity index base oils and additive packages to self-adjust to a wider temperature range than monograde hydraulic fluids. The viscosity of a multigrade is lower below 104° F than a monograde oil having the same ISO viscosity grade. This means the hydraulic fluid will flow faster in cold temperatures, contributing to improved mechanical efficiency. In increasing temperatures, the viscosity of a multigrade fluid decreases less than that of a monograde fluid, providing the necessary volumetric efficiency at higher temperatures. Hydraulic fluids with very high viscosity index (VHVI) base oils provide the best performance.

Energy efficiency evaluation

Petro-Canada recently participated in a hydraulic fluid energy efficiency evaluation on a Denison T6CM mobile vane pump at 2,900 psi. This pump is typically found on a wide variety of mobile equipment in the construction, forestry, mining, and transportation industries. A range of commonly used monograde hydraulic fluids, including ISO 22, 32, 46, and 68 grades, were compared to Hydrex XV All Season multigrade hydraulic fluid.

For this article, we discuss the performance of an ISO 22 monograde (commonly used in winter season conditions) and an ISO 46 monograde (commonly used for summer season conditions). It was necessary to estimate typical average oil temperatures at the pump cartridge under continuous operating conditions for typical mid-size, mid-flow-rate hydraulic pumps during both seasons. This was accomplished by averaging the results of field measurements and incorporating an adjustment for internal heating at the pump itself.

The evaluation showed that 23.8 kW were required to power a hydraulic pump using a winter season ISO 22 hydraulic fluid with a flow rate of 12 gpm. This compares to Hydrex XV, which required 24.2 kW of power with an actual flow rate of 14.6 gpm. The data was calculated at an operating oil temperature of 158° F, a pressure of 2,900 psi, and a speed of 2,000 rpm.The power needed to drive a hydraulic pump using a summer season ISO 46 hydraulic fluid measured 23.9 kW with a flow rate of 12.2 gpm. This compares to Hydrex XV, which required 23.9 kW of power but with an actual flow rate of 12.8 gpm. This data was calculated at an operating oil temperature of 194° F, a pressure of 2,900 psi, and a speed of 2,000 rpm.

The energy required to deliver the same volume of fluid under a given pressure and pump speed (energy efficiency savings) is calculated using the following formula:

EnergyMonograde / EnergyHydrex XV = PMonograde * Qa(Hydrex XV) / [PHydrex XV * Qa(Monograde)]

where P = Power (kW) needed to drive the pump and Qa = actual flow rate (lpm).

Formula

Using this formula with the winter season set above, the energy efficiency savings of the VHVI multigrade can be calculated versus the ISO 22 hydraulic fluid.

Winter energy savings

= (23.8 * 55.3) / (24.2 * 45.3)

= 1,316.14 / 1,096.26

= 1.2005728

= 1.2005728 &endash; 1 * 100

= 20.1%

For the summer season set above, the energy efficiency savings of the VHVI multigrade versus the ISO 46 hydraulic fluid is:

Summer energy savings

= (23.9 * 48.4) / (23.9 * 46.2)

= 1,156.76 / 1,104.18

= 1.047619

= 1.047619 &endash; 1 * 100

= 4.8%

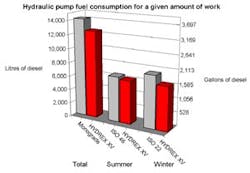

Knowing the energy efficiency savings percentages, the diesel fuel savings that results from switching from an ISO 22 hydraulic fluid in winter and an ISO 46 hydraulic fluid in summer to a VHVI multigrade year round can be calculated. Diesel fuel savings are calculated based on gallons of fuel used for a given amount of work.

Summer:

23.9 kW * 0.048 * 1,000 hrs

= 1,147.2 kWh * 0.0573 gal of diesel fuel/kWh

= 79.3 gal of fuel saved

Winter:

24.2 kW * 0.201 * 1,000 hrs

= 4,864.2 kWh * 0.0691 gal of diesel fuel/kWh

= 336.3 gal of fuel saved

Total: = 79.3 + 336.3

= 415.6 gal of fuel saved

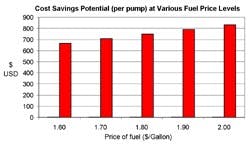

Assuming a diesel fuel cost of $1.72/gallon, the cost savings would be:

415.6 gal * $1.72/gal = $715 per pump

With a fleet of 100 vehicles (total of 200 pumps) the total cost savings to perform the same amount of work would be: $715 per pump * 200 pumps = $143,000 annually.

When considering environmental impact, a fleet of 100 vehicles would conserve 83,123 gal of fuel, corresponding to a reduction of approximately 817 tons of CO2 emissions.

The result shows that by selecting the proper multigrade hydraulic fluid, an operator can significantly reduce fuel use in hydraulic pump operations for a given amount of work, thereby reducing operating costs. For the owner of a medium-sized fleet, this can translate into an annual savings of approximately $143,000. For larger fleet operations, the savings are significantly greater.

The relative performance of available multigrade fluids should be compared before one is selected. All multigrade fluids are not created equal. A VHVI multigrade hydraulic fluid such as Hydrex XV will not only provide good energy efficiency, it also has additional performance benefits.

Hydrex XV is a very high viscosity index, high performance, long-life, anti-wear hydraulic fluid, designed for all season use in heavy-duty hydraulic systems. By removing impurities that can hinder the performance of conventional oils, and blending in specialty additives, it is said to last longer than competitive fluids. It allows hydraulic systems to start at temperatures as low as -40° F, under no-load conditions.

In today's operating environment, where maximizing equipment productivity is essential, switching to a multigrade hydraulic fluid is a significant step to reducing costs. Fuel consumption for a given amount of work may be significantly reduced, seasonal oil changes eliminated and maintenance time decreased. At the same time greenhouse emissions can be lowered. Switching to a VHVI premium multigrade fluid can improve equipment protection even further, resulting in even greater cost savings and equipment protection.

Brenda Jones is a hydraulics engineer with Petro-Canada Lubricants, Calgary, Alta. She acknowledges RohMax USA, Inc., for research information and consultation.