Most engineering efforts focus on ways to design and manufacture products that satisfy application requirements as inexpensively as possible. But you can make a satisfactory design better by making it more reliable and easier to maintain - and without spending a lot of money. How? Simply by following simple tips and recommendations offered by manufacturers. These fundamentals concern bending, alignment, motion, and similar basic guidelines.

Application basics

Unlike metal tubing, hose is flexible, so it is used primarily to allow relative motion between components at either end of the hose assembly and to simplify routing and installation. It is much easier to route a hose assembly over, under, around, or through a series of obstacles than it is to bend and install a rigid tubing assembly. Furthermore, replacing a hydraulic line by fabricating a rigid tube assembly often is more costly and time consuming than making a hose assembly.

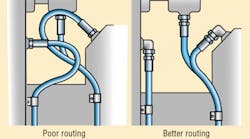

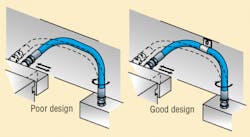

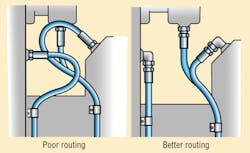

Most manufacturers offer hose that can be bent to a tighter radius than that published in industry standards. Still, bending hose to a smaller radius than recommended should be avoided to avoid shortening service life. Therefore, route hose in a manners that provides ample bend radius, Figure 1.

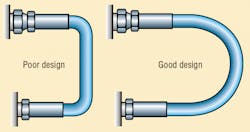

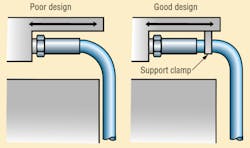

Because hose is flexible, you must allow for contraction and expansion when cutting the hose to length. Manufacturers state that, depending on its type, hose can elongate up to 2% when pressurized, but, more importantly, can contract as much as 4%. This length differential can strain hose reinforcement wires and eventually lead to failure, especially at the hose-to-coupling interface. Therefore, cut hoses slightly longer than needed to compensate for contraction, Figure 2.

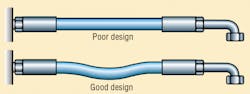

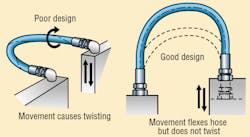

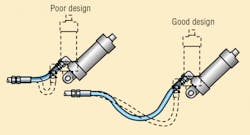

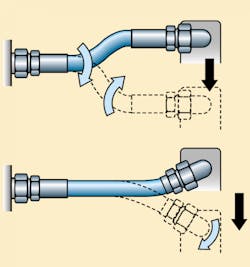

Bend hose in one plane only to avoid twisting its wire reinforcement, which would reduce the hose's pressure capability. Manufacturers state that twisting a high-pressure hose only 5° can reduce service life by 70%, and 7° of twist can reduce service life up to 90%. Unfortunately, hose routing usually occurs late in the design process, so it may be difficult to find an ideal path. Multi-plane bending often can be avoided by reorienting the hose, Figure 3. If this is not possible, install a hose clamp between bends, Figure 4, and provide enough length on both sides of the clamp to relieve strain on the hose's reinforcement wires. This length depends on the hose ID, degree of bending, and helix angle of the particular hose's reinforcing wire, so manufacturers prefer to evaluate each application individually.

Another alternative is to use a single section of hose for each bend and install a hose-to-hose coupling and hose clamp between bends. This technique is less preferred because it not only is more costly and time consuming to perform, but increases the number of potential leak points in the hose assembly. Also, to help ensure that technicians replace and secure hose assemblies properly, include detailed instructions on hose length, use of hose clamps, and special considerations in service manuals.

Providing protection

Hose manufacturers now offer a variety of products with abrasion-resistant covers. No wonder: manufacturers state that about 80% of hose failures are attributable to external physical damage, with abrasion cited as the major culprit. Abrasion is generated primarily by hoses repeatedly rubbing against equipment surfaces or each other.

To help prevent abrasion, use clamps to secure hose in place and keep it from rubbing against adjacent surfaces, Figure 5. The clamp should have a snug fit around the hose to prevent movement, but not be tight enough to damage the hose by squeezing too tightly. Be sure the hose is slack on both sides of the clamp to compensate for contraction and expansion.

Additional protection can be provided by sleeves. Metal sleeves resemble springs that protect the hose from being crushed. Fabric sleeves help keep abrasive particles away from hoses, and both types can serve the added function of nestling multiple hoses into a compact bundle.

Some types of sleeves must be installed from one unconnected end of the hose and slid along its length. Others have a longitudinal slit to enable installing the sleeve without having to disconnect either end of the hose assembly.

Accommodating movement

In addition to causing twisting and abrasive wear, motion can also quickly spell doom for hoses that do not properly accommodate equipment dynamics. For example, hoses connected to a cylinder that undergoes pivoting motion, Figure 6, must be of proper length and routed to avoid becoming kinked or bent beyond their minimum bend radius.

An item that can make a good design better is a swivel joint, sometimes called a live swivel. Unlike standard swivel fittings, which connect hydraulic lines at any fixed angular position, swivel joints accommodate relative motion between the hose and the component to which it is connected. As Figure 7 shows, swivel joints permit pivoting motion that reduces the bending transmitted to the hose assembly and can reduce the length of hose required.

When multiple lengths of hose lie close to each other, and substantial linear motion will occur, hose carriers keep hoses neatly nestled to prevent tangling, twisting, and rubbing against each other. Depending on which particular type is specified, carriers can also isolate the hoses inside from potentially hostile conditions outside - impact from falling objects, abrasive particles, chemicals, or intermittent high temperatures.

Other important considerations

Most hydraulic hose is wire reinforced, which makes it an electrical conductor. For equipment that may be used near power lines or where hose will be in close proximity to flammable solutions that could be ignited by static electricity discharged from the hose, manufacturers offer non-conductive hose.

In other applications, static electricity sometimes may be discharged through the hose wall to surrounding surfaces. This is caused by conducting electrostatic charges from the fluid through the hose's metal reinforcement and cover to adjacent surfaces. Consequences can include localized burning that weakens the hose or even produces pin-size holes in the hose wall. In this case, hose with a conductive tube may be called for to conduct electrostatic charges to hose end fittings rather than through the hose.

Just as twisting can dramatically shorten hose life, so can excessive heat. Heat from external sources, such as exhaust components on mobile equipment, can quickly soften or embrittle the hose wall from the outside in. Therefore, it is important to keep hose away from external sources of heat. If this is not possible, manufacturers offer insulated protective sleeves to partially block heat transmitted to the hose.

However, heat from an internal source — the hydraulic fluid itself — also can reduce the service life of the hose. Pumping hydraulic fluid at a temperature of only about 18° F over the maximum recommended temperature for a hose can cut its expected life in half. What makes this problem even more serious is that machine operators often are unaware that fluid temperatures may exceed manufacturers recommendations - especially if the high temperatures occur only intermittently.

Finally, strive for neat appearance when routing hoses, Figure 8. This not only prevents tangling, twisting, and rubbing together (which can cause abrasive wear), but aids maintenance by making it easy to remove and re-install hose assemblies and trace circuit routing.

Use adapters sparingly because they add to the number of components in an assembly. This increases assembly time, cost, and the number of potential leak points. However, when properly applied, adapters can simplify hose assemblies that use angled fittings (such as 90° elbows) at each end. Hose-end fittings on these assemblies must be carefully oriented to prevent twisting the hose during installation. So using an angled hose coupling at one end of the hose and a straight coupling connected to an angled adapter fitting on the other eliminates the need to carefully align hose ends during assembly.

Clean hose prevents early contamination troublesWhen cutting hose to length, either a serrated or abrasive blade is used. Serrated blades cut one- and two-wire braid and textile-reinforced hose cleanly and efficiently, but usually are not recommended for use on spiral-reinforced hose because the blades would wear quickly or become damaged. Abrasive wheels cut all types of hose efficiently, but produce abrasive debris that usually finds its way into the hose. If not flushed from the finished hose assembly, this debris holds potential for serious wear and damage to sensitive components of the hydraulic system. Skiving and crimping can also produce debris that must be removed before putting the finished hose assembly into service. Skiving involves cutting a length of the outer jacket from the hose to prepare it for accepting a hose-end coupling. Crimping squeezes the coupling onto the hose's inner and outer surfaces, so some residual plating material could come off and find its way into the hose. Compared to skiving and crimping operations, storage can introduce more and a wider variety of contaminants. During storage, dirt, water, metal particles, rust, abrasive particles, and any number of other types of contaminants may migrate into a hose sitting on a shelf. It should be obvious, then, that all hose assemblies should be cleaned before being put into service. At the very least, finished hose assemblies should be cleaned with a strong blast of compressed air. Naturally, this air should be clean and dry. The most effective cleaning technique is high-velocity, bidirectional flushing. This floods the hose assembly with cleaning fluid until the fluid comes out of the hose as clean as when it went in. However, the cost of this equipment and the time required to flush an assembly makes it impractical for many potential applications. A relatively new cleaning technique offers an effective and practical alternative to these procedures by using sponge-like projectiles that are shot through hose and tubing assemblies by a blast of compressed air. Equipment for this procedure is much more affordable than that for high-velocity flushing. Perhaps more importantly, though, it cleans assemblies much more effectively than compressed air alone and in a fraction of the time it takes for high-velocity flushing. Once the hose assembly has been cleaned, be sure to install protective caps or plugs at both ends to prevent contamination from entering the assembly. These should not be removed until the hose assembly is being installed on the equipment. |