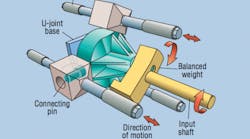

The latest tests of a recent invention, the Sanderson rocker-arm mechanism (SRAM), Figure 1, show advantages for this method of converting reciprocating motion into rotary motion. The low frictional losses of the SRAM pay off in high torque and overall efficiency in hydraulic devices, and may lead to lower heat generation and higher starting torque than with conventional motors and pumps.

Testing was completed by the Milwaukee School of Engineering's Fluid Power Institute under the direction of Tom Wanke.

Operation

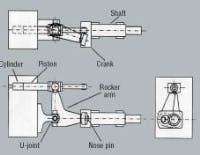

The SRAM uses a rocker arm to convert reciprocating to rotating motion, as described in the August, 2005 issue of H&P. The rocker arm is well known to have little friction as used in overhead valve mechanisms, and it is also used with a 90° change of direction as a means of transmitting motion around a corner with very little friction or lost motion.

In the SRAM motor, this 90° rocker arm has been attached to a Cardan U-joint, so that one end reciprocates in a single plane, and the other revolves in a plane at 90° to the first. This simple and nearly frictionless operation has been adapted to the design of a nearly frictionless hydraulic SRAM motor. Besides the basic advantage of low friction, other advantages are: c the output torque of the motor is absorbed entirely by the U-joint; none is transmitted to the cylinder walls and the pistons run true in the cylinders for minimum friction c the slip-stick starting behavior has been substantially reduced, and c low friction leads inexorably to low wear and long life.

Reduction in friction

The parameter most sensitive to friction is torque efficiency. The SRAM motor is capable of varying displacement from full down to zero and (over center to reverse direction of rotation when operating as a motor or change in flow direction when operating as a pump). Torque efficiency at full displacement exceeds 90% over the speed range of 20 to 800 rpm, a bandwidth of 40 to 1. The specs on this design ended at 800 rpm, but there were no signs of serious tailing off at 800 rpm. Many present hydraulic motors have bandwidths of 2:1 to 4:1, which may require staging to match loads with a wide bandwidth requirement.

As a function of speed, the SRAM motor torque showed excellent classical behavior, rising sharply from zero, rounding off, and then dropping gradually as the speed increases. The behavior tracks closely that of a radial piston motor, which is known for its excellent low speed torque efficiency.

The remarkable feature of this motor is its performance at reduced displacement. Full and fractional displacements are all within a few percentage points of 90% — unprecedented in the world of hydraulic motors.

Another benefit of the reduced friction is the great reduction in internal heat generated by the SRAM motor. Even at full power, a 36-hp motor rises in temperature only 20° F or less. This may be low enough to eliminate the need for oil coolers in many current applications.

How to start up?

The high partial load efficiency leads to an interesting question. What is the best way to start up a vehicle powered by the SRAM motor? Usually, the operator starts with full displacement, and then increases the pressure until the vehicle starts. With slip-stick, it is usually necessary to spike the pressure to get over the region of unstable operation and into the region of smooth operation.

In the specs for operation, it states that such spiking operations can only occur for one second per minute without, presumably, the danger of overheating. This is apparently the best way to start vehicles because the part load efficiency of all existing hydraulic motors is abysmal.

With the SRAM motor's high part load efficiency, it makes sense to start the vehicle by putting the pressure at its maximum value, and then increasing the displacement gradually from zero. The operation should be smooth without any grabbing, and as the power builds the operator will have complete, manageable control over the vehicle.

Motor design

The present motor design is a prototype of a SRAM hydraulic motor, and there are many potential improvements that Sanderson Engine Development intends to implement. The present SRAM motor was designed with little regard for overall weight, cost of parts, etc. — strictly as a proof of concept machine. The next prototype will address some of these practical design considerations.

Some that can be addressed by simply modifying this prototype are as follows:

- Increased horsepower in same weight. The present design is 36 hp at 3000 psi and 800 rpm and weighs approximately 300 lb. Since the nominal safety factor was about 4:1, the weight to power can be decreased by several easy measures such as testing to higher pressure, hollowing out the now-solid pistons to allow testing to higher speed, boring out the cylinders to accept pistons of about 1.5 times the present diameter, and designing hydrostatically lubricated bearings in the U-joint, in the zero-side-load piston joints, and in the large sleeve joint. These measures will decrease the weight-to-power ratio from 8.3 lb/hp to about 3 lb/hp.

- Cost of parts/hp is reduced by all of the above measures in roughly the same proportion, 8.3 to 3, since only minor expenses were added. In addition to the above changes, SED has been able to eliminate a large roller bearing and replace it with a hydrostatic sleeve bearing at a saving of some $750 in parts. Other savings will undoubtedly occur as the design is reviewed by production engineers, and the size of the production run being analyzed increases from one into the thousands.

Conclusions

This report on the SRAM hydraulic motor will be followed by a report on the advances in SRAM hydraulic pumps, which were first reported in the August, 2005 issue of H&P. The curves will be very similar to the above because the low friction of the SRAM makes the two mechanisms near reciprocals of each other.

Eventually, SED will combine the two into an SRAM hydraulic pump/motor that can serve as the backbone of a very efficient energy recovery system, using the reversible pump/motor to recover energy into a hydraulic accumulator. Because hydraulic pumps, motors, and accumulators are much more efficient than electric motors, generators, and batteries — and because energy can be stored hydraulically and recovered hydraulically at a much higher rate than can be done electrically — there may be a bright future for the hydraulic hybrid vehicle.

SED estimates the round trip energy recovery efficiency of this system with SRAM motors and pumps, and SRAM motors on the wheels, all of which are around 90% efficient, to be in the neighborhood of 60%. This is more than double the energy recovery of the nearest competitor, the electric hybrid vehicle.

This discussion was contributed by Albert E. Sanderson, vice president of R&D, Sanderson Engine Development. For more information, visit www.s-ram.com.