How do you lift millions of pounds hundreds of feet into air? Very carefully, of course. But moving such massive payloads is no joking matter, where safety must come first. Therefore, you probably won't hear any complaints that the world's largest mobile crane rotates at only 1 /8 rpm.

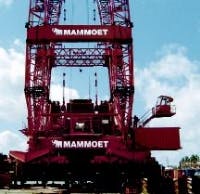

The huge machine that tackles these difficult jobs is the PTC III, from Mammoet Group, Rotterdam, Netherlands. Like the mammoth (Mammoet is Dutch for mammoth), the cranes that Mammoet develops are known for their huge size, strength, and ability to thrive in hostile conditions. Recently, Mammoet commissioned the largest mobile crane in the world, the PTC III. It stands 200 m tall and can lift 1600 t at speeds to 80 m/min. It was developed to handle heavy conveyor systems used in the oil industry for maintenance work.

But size, weight, and strength may not be the most impressive aspect of this machine. PTC stands for Platform Twin-ring Containerized, where twin-ring refers to the crane's construction, and containerized meaning that it can be disassembled and transported by standard means. The crane is supported on a steel ring, with 54 wheels on four bogies to allow its tower — driven by gears through hydraulic motors — to rotate through 360°. When disassembled, the entire crane fits within 88 standard marine shipment containers that can be transported readily by ship, rail, or truck.

Ideal application for hydraulics

The idea of a hydraulic drive for the rotary drive came up very quickly, explained Jan van Seumeren Jr., technical director at Mammoet. "Naturally, the winches and drive wheels could have been driven electrically. But we would have needed very large motors and generators for on-site supply." Large electric motors could have prevented the PTC III front meeting space and/or weight requirements for shipping. Furthermore, heavy, bulky motors could have made assembly and disassembly more difficult.

The PTC III relies on a 20-ft tall, diesel-driven power supply that drives electric generators and 17 hydraulic pumps. The pumps drive 29 hydraulic motors that each drive a planetary gear drive. The hydraulic motors provide the mechanical power to drive the wheels through the gear drives, and each gear drive multiplies torque from the motor and allows it to rotate at a more efficient speed than if the motor drove the wheel directly.

Collectively, the wheels transmit the torque to rotate the tower up to 1°/sec. Van Seumeren says the gear drives are lubricated with hydraulic fluid, and the the entire hydraulic system holds roughly 8000 l of fluid. Pumps, motors, and gear drives were all provided by Bosch Rexroth BV, Boxtel, Netherlands.

Bosch Rexroth's involvement was not only as a supplier, but as a development partner that became involved in the project at an early stage, says van Seumeren. "We selected as many components as possible from the Rexroth standard range." He points out that service was also an important consideration. "Bosch Rexroth has a worldwide service organization and already has a service support center or its own subsidiary practically everywhere we go."

The PTC III is the fifth twin-ring crane Mammoet has designed and built in cooperation with Huisman-Itrec, Scheidam, Netherlands. It weighs 2100 t, so it can lift more than 3 /4 its own weight.

Design considerations

Perhaps the most challenging design requirement of the PTC III design was that all crane parts had to be transportable within 88 standard 20- or 40-ft shipping containers with a maximum weight per container of 30.4 t. Standard containers and weights mean permits and escort vehicles are not required for truck transport.

For marine transport, each container can be handled in terminals at standard rates, and rail transport is also routine. These all add up to substantial savings in transport charges, time, and effort. In fact, transport costs of the PTC III are about half that of cranes with a comparable lifting capacity.

Much of this savings can be attributed to hydraulics because it transmits high power from relatively small, lightweight components. In addition, most parts have a double function, one during operation of the crane and one during transportation of the crane. For example, ballast blocks at the end of mast sections can be assembled to form containers.

Another requirement was to minimize assembly time. Normally, cable must be unreeled in preparation for shipping a crane, but with the PTC III, unreeling is unnecessary. This not only saves time prior to transport, but when the crane is reassembled at a new job site as well.

Structure

The upper structure of the crane's slew ring consists of two longitudinal beams, connected by quick connection pins to one transverse beam at the front. Multiple components — such as the power pack, lower ballast beam, upper ballast beam, several winches, backmast erection frame, boom stops, and operator cabin — are mounted on a longitudinal beam. All components feature modular design with quick-connection pins to enable rapid assembly and disassembly. As many components as possible are made identical so they are interchangeable.

For example, front and rear bogies are identical. Each axle is hydraulically driven to enable smooth slewing motion and free rolling. Most winches — hoist winches, topping winch, back-mast erection winch, and an auxiliary hoist winch — share a similar design to simplify assembly and disassembly procedures. Each winch has a 52-mm wire and a maximum line pull of 60 t.

Track drives for propulsion

However, one more requirement still hasn't been mentioned — the PTC III is also self propelled. Cranes often need to be moved to different locations within a job site. You might expect a crane of this size to require at least partial disassembly before being moved. But the PTC III's rigid ring construction also serves as a stable transport chassis. When the crane needs to be moved, four track drives can be deployed via massive cylinders, to lift the base off the ground. Hydraulic motors then actuate each track drive to move and steer the PTC III to a new location at the job site. Considering its size, it is easy to maneuver and can be operated in relatively tight areas.

A multitude of materialsThe PTC III is a marvel of engineering encompassing more than its hydraulic system. For example, its construction required: 1000 t of steel for the structure 2100 m of electrical cable 5300 m of 50.4-mm steel cable and 2650-m of 30-mm steel cable 1500 t of steel for counterweight 1280 m of hydraulic hose 6000 l of hydraulic oil 6000 l of paint. |

Henk Veulings, branch manager — mobile hydraulics, Bosch Rexroth BV, Boxtel, Netherlands, provided technical details on this application.