Today's farms are managed like large businesses. In the continuing trend to improve productivity and increase yield, equipment is pushed to the limit. At the same time, precision agriculture is changing traditional practices. So new machines must be more durable, reliable, and provide more versatile and efficient operation.

To meet these challenges, the trend in self-propelled agricultural machinery is to reduce or eliminate all unproductive tasks that reduce the overall output of a machine. As a result, new equipment designs aim to improve cab layout, reduce on-road transport time, increase machine size to boost throughput, increase working speed, and lower operational costs - especially fuel consumption and tire wear.In the field of hydrostatic transmissions, a new concept of high performance transmissions based on pure hydrostatics has emerged: Speed+. The Speed+ concept is characterized by:

* a wide transmission ratio, which provides high gradeability performance in the field and high speed on the road,

* high efficiency at all speeds for optimum fuel consumption,

* automatic speed shift with continuously variable speed from 0 to 65 Km/h, ensuring best transmission configuration for any circumstance,

* multiple drive modes,

* speed control,

* dynamic braking management,

* anti-stall and diesel engine power management,

* traction control management, and

* default diagnostics.

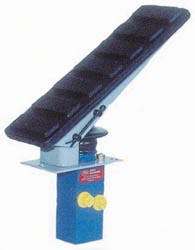

A key element of these transmissions is the model MW multi-speed motor, which consists of a multi-speed cam-lobe hydrobase and high capacity bearing supports to accommodate larger, heavier machines. The MW also features dynamic and static brakes.

Higher efficiency with direct drive

The MW motors have multi-speed hydrobases, a high displacement ratio, and a maximum rotational speed of 250 rpm, which makes the Speed+ transmission especially well-suited to agricultural applications. They provide high gradeability performance in the field, and high speeds on the road, above 40 km/hr and up to 65 km/hr for sprayers.For example, one can create a six-speed transmission using four 4-speed motors to obtain a wide range of speed and torque combinations:

Based on direct drive cam-lobe technology, MW motors have fewer moving parts than a motor-gearbox combination. Furthermore, the direct-drive motor maintains its mechanical efficiency across the whole spectrum of rotating speeds - from 1 to 250 rpm. On the other hand, a high-speed motor coupled to a gearbox exhibits a significant drop in mechanical efficiency at high speeds. Ultimately, then, the efficiency of the entire hydrostatic transmission suffers.

The higher efficiency can mean higher productivity, because less downtime will be spent refueling. But higher efficiency isn't the only benefit of the Speed+ drive system. In the Startup mode, full torque is available immediately. In the Field mode, less power is used by MW motors at work speed, so more power is available for implements. In the Road mode, the higher efficiency of direct drive at high speeds means the vehicle will consume less fuel.

Anther advantage of multi-speed cam-lobe motor is quieter operation at high speeds. Plus maintenance is simplified because only one hydraulic oil is needed. With a motor-gearbox combination, the gearbox requires requires gear oil, while the motor requires hydraulic oil. Requiring only one fluid only reduces inventory costs, but reduces the likelihood that the wrong fluid will be used.

Benefits of the motor

The MW motor itself features high-capacity bearing supports - a more compact assembly if external bearings support the load. Integrated static or dynamic brakes - or both - add to the compactness of the direct-drive motor.

The bearing support is designed to accommodate the wide variations of loads and orientations encountered in the field applications. This is especially important as machine weights and speeds increase.

The motor's Dyna+ brake is integrated around the bearing support and can perform three braking functions - parking, emergency, service. This feature has enabled agricultural machinery manufacturers to achieve international TUV compliance for dynamic braking. The brake keeps its braking characteristics after 25,000 dynamic operations. And because the brake is continuously flushed by hydraulic oil, it maintains a constant temperature. Again, a single grade of hydraulic oil is used for the entire hydrostatic transmission.

Furthermore, brake torque is applied directly to the wheel rim, so torque is not transmitted through the shaft splines, thereby eliminating the potential for shaft fatigue that can occur with conventional designs. To further reduce potential maintenance, life of the brake discs exceeds that of the motor. So the downtime otherwise needed to replace brake disks is eliminated.

Finally, the external design of bearing supports and integral brakes prevents any fibrous material from the field from wrapping around the wheel shaft, which otherwise could damage the motor's seal.

Electronic transmission control

For traditional equipment designs, the MW motors can be used with manual control pumps. In such cases, speed control will occur in steps - operation similar to that of three- or four-speed transmissions. This characteristic is typical of cam lobe motor technology. However, leading tractor manufacturers have already initiated a trend in agricultural machinery - continuously variable transmissions (CVTs).Operators have become accustomed to greater convenience, easier use, and less operator fatigue offered by CVTs. And managers and operators alike understand the benefits that electronically managed transmissions bring to their businesses in terms of overall man-machine productivity.

Consequently, what they have come to expect in tractors, they also want in more specialized self-propelled agricultural machinery. Electronics offer great flexibility in customizing machines. From identical hardware, one can easily achieve completely different machine performance and behavior, just by adjusting control parameters or by reprogramming on-board software functions.

Electronics improve the vehicle safety thanks to continuous monitoring and safety programs. electronics also protect the machine from improper use that could damage or destroy sensitive components. Fast on line diagnostic programs help solve any issues in an efficient and professional manner.

Automatic transmission

On-board computers and software can be specifically designed to control hydrostatic transmissions that use cam lobe motors. Moreover, the controls can simultaneously manage the diesel engine, pump displacement, and displacement of each wheel motor. This allows incorporating useful automatic functions, such as:* automatic speed shift with continuously variable speed from 0 to 65 Km/hr, which ensures the best transmission configuration under any circumstance,

* dynamic braking management, which can vary the ratio between hydrostatic and mechanical braking, and

* traction control management to achieve independent wheel-to-wheel drive control.

On-board electronics can interface with any cabin controls, such as a brake pedal, joysticks or both, and communicate through CAN bus. Electrically controlled Series SA pumps contain a non-contact sensor that provides continuous output of the the swashplate position. This allows closed-loop pressure and flow control. The pump also achieves fast response - a 75-cc/rev pump can go from neutral to full stroke in 200 msec.

Such performance is key to an efficient CVT. The instant the on-board computer executes a command to change motors displacement, it simultaneously executes a command to change pump displacement accordingly, so vehicle speed does not change.

For more information, contact Poclain Hydraulics, Sturtevant, Wis., at (262) 321-0676, or visit www.poclain-hydraulics.com.