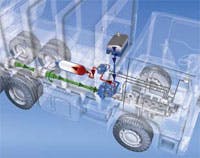

The city of New York teamed with Bosch Rexroth Corp., Rochester Hills, Mich., to examine and test the use of hybrid vehicle technology in refuse trucks. Bosch Rexroth was chosen by Calstart’s Hybrid Truck Users Forum (HTUF) to contribute its Hydrostatic Regenerative Brake (HRB) parallel hydraulic hybrid system to the project, which will be deployed and tested in New York. The HRB system includes a hydrostatic hybrid drive that uses hydraulics instead of batteries to substantially reduce fuel consumption, even in heavy commercial vehicles.

Bosch Rexroth, Crane Carrier Co., and ISE Corp. make up the supplier team for the HTUF project. During testing, the hybrid trucks are expected to demonstrate 30% to 50% reductions in fuel use and emissions. The field tests are designed to authenticate both technical and economical characteristics of the HRB system. The results should provide a solid foundation of HRB’s potential, eventually leading to large-scale deployment of in-service and new vehicles. The HRB can be integrated and even retrofitted into the chassis as an add-on system without major modifications.The HRB system will power the Crane Carrier LET2 chassis in the trucks and will be integrated with a Heil refuse body hydraulic system for weight savings and efficient packaging. It uses a hydraulic pump-motor, connected to the drive line to capture kinetic energy during vehicle braking. When braking, the pump-motor acts as a pump, absorbing energy from the drive line and imparting a retarding force on the drive wheels.

The system uses the absorbed energy to charge a nitrogen-pressurized accumulator, which stores the potential energy of the incoming fluid. During acceleration, the pressurized gas pushes fluid out of the accumulator, and the pump-motor then acts as a hydraulic motor, assisting the engine and reducing fuel required to launch the vehicle. The overall process is referred to as regenerative braking.

Hydraulics fits the bill

Hydraulic hybrids are better equipped to cope with the extremely high power-handling requirements of regenerative braking, and they require fewer energy conversion steps that reduce efficiency. In this way, hydraulic hybrid systems have the potential to capture a larger portion of the braking energy and make use of it more effectively than electrical systems can.

When the driver presses the brake pedal, controls route hydraulic fluid into a high-pressure reservoir. The resulting resistance makes the vehicle decelerate. When accelerating, the high-pressure reservoir is controlled electronically to release the pressure to reduce the load on the vehicle’s engine. As a result, the engine consumes less fuel, generates less exhaust gases, and functions more quietly.

The system reduces fuel consumption by up to 25% in vehicles that require frequent stops and starts, such as urban buses, garbage trucks, fork lift trucks, or delivery vehicles driven in city traffic. Fuel consumption can also be reduced considerably in other commercial vehicles and trucks used for intercity service.

The hydrostatic hybrid drive functions almost maintenance-free and wear-free compared to electric hybrid drives. For example, it is not necessary to regularly change any batteries. The HRB also improves the acceleration of the vehicle. The additional drive energy allows vehicles to be equipped with smaller diesel engines and, therefore, further reduce fuel consumption and emissions.

Visit www.boschrexroth-us.com or fluidpowertalk.blogspot.com for more information and online exclusives about additional Bosch Rexroth hybrid technology.