All around the world, large construction projects depend on cranes to move heavy loads around a job site. Whether the crane is stationary, has a crawler drive for mobility, or is truck-mounted, Figure 1, a slew (swing) drive serves as a key element for high productivity and precise positioning — especially considering that boom lengths and hook weights continue to increase.

A new slew drive module, the Rexroth MSC16, systematically combines tried-and-true hydraulic design elements with directional valve concepts optimized for crane slew drives. The valve supports the options of electrohydraulic subsystems while offering cost benefits for crane manufacturers.

Hydraulic circuits on cranes

One of the greatest challenges for the hydraulics of vehicle-mounted cranes is providing enough power to accomplish all three primary movements (lifting, turning, and tilting) simultaneously — and independent of each other when necessary. If only one movement is needed, the option should be available to concentrate the entire hydraulic power on this movement. Doing so maximizes no-load speed, which, in turn, boosts productivity.

Besides the primary functions of controlling a crane's hoist and rocking gears, winch, and telescopic boom, the hydraulic system must also provide fast, powerful, and precise control of the crane's slew drive. The design and configuration of the slew drive needs careful consideration because load distribution can change. Wind can even affect the load distribution, especially when large loads are involved.

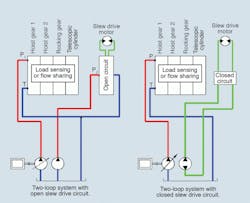

Winch drives typically are powered by a motor driving a spur gear that meshes with the internal teeth of a ring gear. Cylinder and winch controls typically are combined in a single main block, but slew drives typically use a separate open or closed circuit, Figure 2. Open circuits generally cost less than closed circuits and provide greater freedom in the design of the control system.

Control technology

The control technology used in mobile hydraulic systems has always differed from that of industrial hydraulics. Industrial hydraulic systems tend to make wide use of industry-standard components, whereas mobile hydraulics tend to use more non-standard components. Mobile hydraulic control systems used today range from mechanically operated open-center valves fed by fixed-displacement pumps to CAN-controlled directional valves with integrated onboard electronics and integrated sensors fed by variable displacement pumps.

However, standard valves, such as load-sensing and flow-sharing directional valves, have reached their limits of flexibility and degree of freedom when it comes to adapting an actuator — in this case the slew drive — to positive and negative loads. Six-way throttle valves (also known as open-center valves) have proven to be robust and inexpensive control systems in the field of mobile equipment. Here, a fixed-displacement pump feeds the hydraulic system. This design is especially prevalent on small and some medium-sized construction machinery, tractors, and fork lift trucks.

Comfort enhancements and the demand for increased productivity mean that hydraulically operated pilot valves are increasingly being used. However, one drawback of open-center valves is that they have a large dead band (up to 30% of the piston spool stroke) upon initial actuation. The dead band is necessary to feed the entire speed-related oil flow from the pump to tank with minimal power loss when the system is in neutral.

Another drawback of open-center control can be the high level of pressure-dependence at the start of movement. This is because recirculation first must be accumulated until the load pressure is achieved. Only then does movement begin. Movement starts earlier at low pressures and loads, and accordingly later at higher pressures. In particular, if direct joystick actuation is employed, different joystick positions will result for different loads.

Dead band hinders fine control characteristics, and attempts to eliminate dead band has lead to the development of closed-center valves with upstream or downstream pressure compensation. These allow an evenly distributed, fine control range to be achieved in parallel operation and in the supply with fixed- or variable-displacement pumps.

Although load-sensing valves are characterized by flow control and simple options for influencing pressure, flow-sharing valves make use of flow distribution to provide a smooth supply for all actuators. This adantage has led to wide usage of flow-sharing valves, especially on compact construction machinery — which often operates mechanically or hydraulically and frequently has to serve several actuators at once.

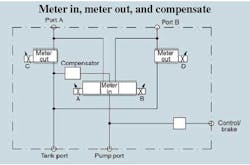

When configuring control systems, consider that almost all valve designs usually work only with meter-in oil flow. However, high cylinder speeds and negative loads can cause severe cavitation to occur under certain conditions. Loss of control, damage to the cylinder (primarily at the seals), or both can result.

The slew drive module

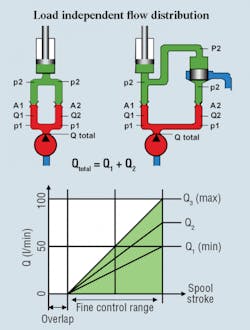

Previous valve designs already satisfied the above demands for a crane slew drive and were systematically orientated towards motor-driven load requirements. A key advantage of the MSC16 slew drive module, Figure 3, over previous designs is pressure compensation downstream of the recirculation duct and the separation and option of a separate control system for meter-in and meter-out functionality. Downstream recirculation pressure compensation is similar to flow sharing. It is based on the principle of load-independent flow distribution (LIFD), Figure 4.

Here, the oil flow is parallel-partitioned between the circuit and the slew drive motor via two metering orifices (A1 and A2) with corresponding cross-sectional areas and curves. A load-recording circuit transmits the working pressure P2 to the pressure scales downstream of the recirculation flow so that the pressure after metering orifice A2 (recirculation) is the same as the working pressure. If production tolerances and friction in the pipes are neglected, the pump oil flow is partitioned as follows according to the cross sections of the metering orifices:

Q1 ÷ Q2 = A1 ÷ A2

Linear oil flow (corresponding to the spool piston cross-sectional configuration) is beneficial with this switching control system regardless of the pump's meter-in flow, and for the fine control range to remain constant. As described above, no reduction of resolution across the piston spool stroke occurs. Therefore, we can assume that:

Q 1 = flow rate with reduced pump drive speed,

Q 2 = flow rate with maximum pump drive speed, and

Q 3 = flow rate with additional pump summation.

An important feature of the slew drive module is that it accounts for negative loads, such as those encountered in the braking phase on slew drives. Meter-in and meter-out notches are consistently separated, and they can not be actuated separately. Because pressure differentials at the metering orifices depend on the pressures encountered during acceleration and deceleration, resolution of the metering notches by means of variable hydraulic loading can be employed to induce either optimized acceleration or cavitation-free deceleration. Pressure sensors on the slew drive motor can be used to realize further optimization, including driver-dependent and driver-selectable braking characteristics and torque regulation.

A float position can still be achieved by charging the two meter-out valves, without having to accept additional elements or compromise fine control.

Strightforward results

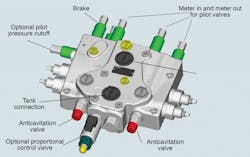

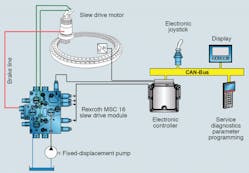

The MSC16 slew drive module contains all functions needed for a crane slew drive, Figure 5, and a typical system incorpoarting the valve is illustrated in Figure 6. The MSC16 module provides a compact and cost-effective control system for slew drives. Because it was developed on the basis of fundamental hydraulic circuits, the module compensates for speed-related pump input and load fluctuations on the slew drive caused by the moments of inertia. The result is fine control without additional extension of sensors and electric control circuits.

Electrohydraulic piloting means the slew drive module can be incorporated into existing vehicle designs and wiring and system architectures. Incorporating pressure sensors into the slew drive control subsystem produces the highest precision and range optimization of a crane. This future-orientated solution ensures that crane operator's requirements with respect to function, safety, and costs will be satisfied even as they become more demanding.

Contact Helmut Fischer, Bosch Rexroth AG., Lohr, Germany via e-mail at [email protected]. Click here to view and download a PDF brochure from Bosch Rexroth: "Drive and Control Systems for Cranes."