Die casting and injection molding machines place some hefty demands on hydraulic systems. They must operate with high repeatability to ensure high product consistency and low scrap rate. But first and foremost, they must operate with the highest possible throughput to maximize productivity in order to minimize cost per part. And don’t forget reliability, which is a big reason why hydraulics is used so often in these applications.

A key to a machine’s high productivity lies with the motion control system of its main hydraulic cylinder — which injects molten metal or plastic into a die cavity. The challenge is to move the cylinder’s piston rod quickly during non-injection portions of a cycle while offering precise pressure control near the end of an injection cycle to ensure high quality and consistent parts.

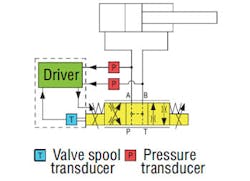

Electrohydraulic proportional directional control valves with pressure and flow (P/Q) from Atos Spa, Sesto Calende, Italy, lend themselves to the requirements of plastic injection molding, metal die casting, and cushion control of vertical presses.These valves add pressure control to the conventional closed-loop control of a proportional valve’s spool or poppet. The valve is commanded by two reference signals, flow and pressure (or force). A dedicated algorithm automatically selects which control is active based on feedback and time in a cycle.

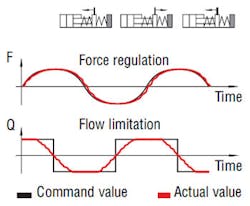

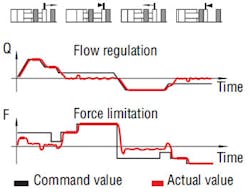

Flow control is in command when hydraulic pressure is lower than the relevant reference signal. Conversely, pressure control becomes active if the system’s pressure reaches or exceeds this value.

Any of three basic functional schemes can be used to fulfil the most common motion control applications:

• pressure control with one remote pressure transducer. Closed-loop pressure control is performed by interfacing the valve with one remote pressure transducer.

• force control with two pressure transducers. Closed-loop force control of the cylinder is accomplished by interfacing the valve with two remote pressure transducers installed at the cylinder’s work ports. The actuator force is calculated by the pressure feedback balance (Pa – Pb).

• force control with a load cell. A load cell is installed between the piston rod end and the load. This setup provides the most accurate application of force by measuring force directly.

Integral digital electronics offer easy software settings by Atos’ E-SW/S tool. The software also improves motion dynamics and controllability and diagnostics. Programming interfaces include Serial PS, Fieldbus BC (CANopen), or Fieldbus BP (PROFIBUS-DP).

Of course, the P/Q concept and electrohydraulic proportional valves can be applied to other applications requiring closed-loop pressure and force control, and quick and easy tuning.

For more information on Atos’ electrohydraulic proportional valves with P/Q control, visit www.atos.com.