Ensuring clean, contamination- free air is critical in medical and instrumentation applications. That’s why new valves from Clippard Instrument Laboratory Inc., Cincinnati, have undergone an intense cleaning process. They have been ultrasonically cleansed, assembled, inspected, and tested in an enclosed and controlled area with a state-of-the-art positivepressure, high-efficiency particulate air (HEPA) filtration system.

The Oxygen Clean series electronic valves were designed for use with oxygen applications but suit low-pressure pneumatic applications for compressed air. They are available in 2-way or 3-way, normally closed or fully

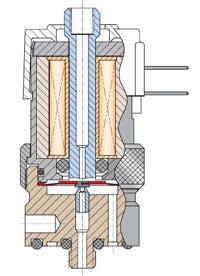

Dubbed, the “OE” series, it uses a proprietary valve system. Most solenoid valves use a plunger that moves up inside a coil, making the system heavy and slow to react because it has so much momentum. A spider spring and armature reduces mass and allows it to react quickly.

Clippard’s design engineer, Rich Humason, says the valves will suit medical and instrumentation applications, where even the smallest particulates could cause serious damage down the line. “These valves have gone through a very detailed cleaning process because they are designed for use with oxygen,” Humason says. “But in order to do that, we needed to make sure we removed out any hydrocarbons or particulate matter. So this is a great benefit to anyone who needs to use a clean valve.”

Three models are available — a 0.025 in. orifice valve with pressure ratings of 105 psi and 0.6 scfm at 100 psi; a 0.040 in. orifice valve with pressure ratings to 50 psi and 0.5 scfm at 50 psi; and a 0.060 in. orifice valve with pressure ratings of 25 psi and 0.45 scfm at 25 psi.

The valves have a low power consumption of only 0.67 W, a response time of 5 to 10 msec, and voltages of 6, 12, or 24 Vdc.

For more information, visit www.clippard.com/oxygen-h or e-mail [email protected].