Smart design can substantially reduce the energy consumption and operating costs for a pneumatic system.

By Thomas Dwyer

Bosch Rexroth Corp.

Pneumatics Div.

Lexington, Ky.

Dimensional gauging can consume a substantial amount of compressed air. The MS01 Part Sensing System uses one-half the air of a typical bridge-configuration system. It compares a pressure difference across a single orifice, as opposed to the bridge circuit that compares back pressure at the nozzle to back pressure at a constantly leaking orifice.

Series 261 plug-in valves, shown in ISO sizes 2 and 3 with a sandwich regulator, substantially reduce compressed air consumption when compared with conventional valves. Key features include a packed spool rather than metal-to-metal sealing, and a regulator that differentiates forces for push and pull cylinder strokes.

Pneumatic directional-control valves with metal-to-metal spool seals are plagued by significant and constant leakage, even when the valves are not in use.

In August 2003, the heartland of U.S. manufacturing found itself in the dark, as production ground to a halt. Much effort has since been spent on preventing a recurrence of the 2003 blackout. For many companies, this brought about a renewed focus on energy and associated costs related to pneumatics in manufacturing.

For instance, one of the largest automobile manufacturers — and thus a company that endures the high energy costs of compressing air — has expressed an explicit desire to eliminate pneumatics from the vehicle assembly process within five years. The reason is the perceived energy savings from alternative technologies.

If only solutions were that simple. In reality, there are many cases where pneumatics provides the ideal means of motion-control in manufacturing processes. These include applications that involve:

- linear or rotary speeds to 13.2 fps

- forces to 20 kN (4550 lbf)

- linear actuation distances to 33 ft or infinite rotation.

- multiple speeds and forces (including closed loop) from the same drive.

Pneumatics also offers other advantages over competing motion and control technologies. For instance, pneumatic systems are selfcleaning and offer excellent corrosion resistance, making them reliable in tough environments and easy to maintain. They quickly compensate for changing loads, offer inherent overload protection, and intrinsic safety.

Modern pneumatic control provides simple, direct, modular links to all standard fieldbus protocols, offer nonmarking and even noncontact material handling, and can store energy to compensate for lack of electrical power. They even offer multiple-position control via pneumatic servodrives.

Saving energy

The answer to reducing energy costs lies in reviewing how different manufacturing processes use compressed air and taking advantage of designs that minimize energy consumption. Let's start with the basics. The pneumatic energy used to perform a task is a function of the pressure and volume. In typical pneumatic systems, volume equals cylinder volume plus the volume of the pipe between the valve and cylinder. These volumes are typically pressurized and emptied each time a cylinder extends or retracts. The combined cylinder and pipe volumes should ideally only be charged to the pressure required to successfully stroke the cylinder. Exceeding this pressure wastes energy, and it is easy to both calculate the correct pressure and reduce overpressure.

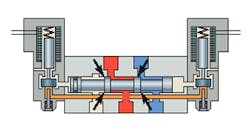

In many applications, there is a large difference between the cylinder force required to extend versus retract. The vast majority of pneumatic control systems apply the same pressure for both extend and retract strokes. In addition to wasting energy, charging a cylinder to a higher-than-necessary pressure increases noise, vibration, and leakage — therefore, reducing the system's mean time between failure. Higher pressures also reduce cylinder speed, because the cylinder wastes time charging beyond the level required, and it takes longer to empty the chamber.

To illustrate the problem, we will estimate the percentage of energy used to compress air that is wasted by pressurizing cylinders beyond the levels necessary to stroke a cylinder. First, assume a high figure for leakage, say 30% (which in itself is magnified by over-pressurizing). Then 70% of the total energy would be used to pressurize and empty the cylinder.

Break that down into 35% each for push and pull loads, and assume that each cylinder is sized correctly for the load (which is highly unlikely). Then, even with a 2: 1 ratio of loaded versus unloaded cylinder stroke, about 17% of total energy is wasted. In reality, the waste due to overpressurizing far exceeds 17%, because any cylinder that is oversized and any excess pipe volume between the valve and cylinder also wastes energy.

Many practical, lowcost components control individual cylinder pressure and help eliminate energy waste. On subbase-mounted valves, sandwich pressure regulators independently control a cylinder's load and nonload pressure. Elbow pressure regulators provide another easy and low-cost solution. These compact devices look like elbow flow-control valves, but they control pressure. The regulators have a built-in check valve for reverse flow and a dial to indicate pressure settings.

Reducing volume

The development of decentralized fieldbuses for pneumatic-valve manifolds enables designers to reduce the distance between valve and cylinders. This reduces pipe volume. In fact, from an efficiency standpoint, the ideal place to mount a valve is directly on the cylinder, completely eliminating piping.

Reducing pipe volume between the valve and cylinder saves energy even if pipe volume increases between the compressor and valve manifold. That is because the volume between valve and cylinder pressurizes and empties every cycle, whereas the volume between the compressor and valve manifold rarely empties.

Some bus protocols, such as AS-Interface, enable a simple, lowcost serial link to a single valve. This lets designers mount valves on the cylinder, considerably reducing air consumption.

Another common application in machining and assembly is pneumatic gauging. Back pressure from air flowing through a fixed orifice can verify whether or not parts conform to dimensional tolerances as small as 0.01 mm. In many cases, the gauge uses a bridge circuit that compares a constant bleed of air to airflow through the section or dimension being tested.

An energy-saving alternative is to use a sensing system that compares pressure drop across an orifice in the flow path. It can cut air consumption by 50% for the same application. Precision air sensing can take less than 200 ms. An air-saver valve that limits flow to 200 ms/cycle further reduces air consumption.

Addressing leakage

Another factor that affects the costs of compressing air is the inherent leakage in valve spools. For example, an estimated 30% of pneumatic spool valves sold in the U.S. rely on metal-to-metal sealing, which has inherent disadvantages compared to alternative sealing concepts. A metal-to-metal (or lapped-spool) valve leaks an estimated 0.6 to 0.7 lpm even when new. In comparison, packed-spool valves, such as a Rexroth ISO-standard valve, leak a maximum of 10 to 30 cc/min up to a minimum of 20 million cycles. (Also, this leakage is from the main air supply in the valve out to atmosphere, and is constant whether or not the valve is energized.)

Consider a small assembly plant with 2500 valves. A conservative estimate of constant air consumption = 2500 valves X 0.6 lpm = 1500 lpm or 53 scfm. A reasonable estimate for energy costs of compressing air is $0.16 per 1000 scf, so there would be a constant loss of $0.48/hr or $4055/yr — just on the difference between two spool designs. For larger users, or in regions with higher energy costs, the difference can be dramatically higher.

Estimating energy and cost savings

A well-designed pneumatic system can substantially reduce energy costs when compared to traditional air systems. This example for a typical plant pneumatic system results in a conservative annual cost savings of over $68,000. The estimate assumes 2500 valves and cylinders, with valves mounted 4 ft from the cylinders. Average cylinder bore is 2 in. and average stroke is 6 in. The system runs 16 hr/ day, 6 days/week, 50 weeks/yr, and includes 50 part-present sensing applications.

Here are the design parameters for the optimized system:

- Instead of the same pressure for extend and retract strokes, the optimized system reduces retractstroke pressure from 90 to 45 psi.

- Divide by 4 for the cost savings per foot of mounting a valve closer to the cylinder using 1/4-in. ID tubing.

- Valves with typical metal-tometal sealing leak whenever there is a pressurized air supply, even when there is no production. Thus, leakage takes place 24 hr/day, 7 days/week, 50 weeks/year.

Yearly cost savings (conservative)Cause of increased air consumption1

(1) Assumes 2500 valves and cylinders, valve mounted 4-ft from the cylinder, average cylinder bore of 2 in. and stroke of 6 in., 10 cycles/min, 16 hr/day, 6 days/week, 50 weeks/year and 50 part present sensing applications. |

For more information contact the author at (859) 254-8031, or visit www.boschrexroth-us.com.