The Old Timer of Royal Oak, Mich., was a regular contributor to H&P years before we ever even heard of the internet. But most of his advice is just as useful — and interesting — today.

So rather than leave his wisdom printed on pages archived in our storage room, I pulled out issues from the late 1980s and early 1990s and have been reproducing relevant entries in this blog. Here is my 18th entry, which was originally published in the June 1989 issue:

Avoid unwanted intensification

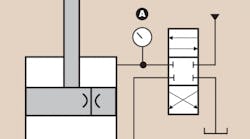

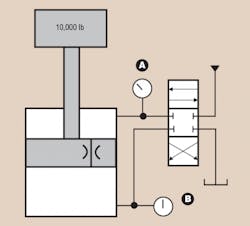

Most hydraulics courses include an example to illustrate an intensification problem that occurs when holding vertical loads with a cylinder. Typically, such an example might specify a cylinder with 10-in.2 piston and 1-in.2 rod lifting a 5-ton load. A blocked-center directional control valve stops the cylinder in mid-stroke. The student usually is told that the piston has a small orifice drilled through it. (A more realistic condition is the inevitable leakage past worn piston seals.)At the moment the valve stops the piston, gauge A reads 0 and gauge B reads 500 psi. What’s the new reading on A?

The force on the piston now is the load plus a pressure component generated by 500 psi acting on the 9-in2 annular area—or a total of 14,500 lb. A pressure of 1450 psi in the cap end of the cylinder is necessary to support this force.

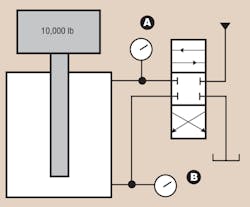

When the pressure at A rises to 1000 psi, the pressure component increases to 9000 lb—for a total force of 19,000 lb. Gauge B now registers 1900 psi.

The ultimate question is, “How far will this intensification progression go? What will be the maximum pressure in the cap end of the cylinder?”