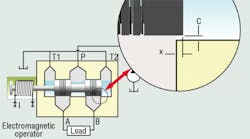

Why do spool valves in hydraulic systems sometimes stick? In a word: contamination. The radial clearance between the spool and bore in common, garden-variety directional control valves ranges between 3 and 13 microns. And in practice, perfectly round and straight bores are difficult to achieve (this is why servo and servo-proportional valves are fitted with a sleeve between the spool and bore--for high precision). As a result, the radial clearance typically varies across the length of the spool. This influences spool friction--but so too does the cleanliness of the oil.

If the clearances between the spool and bore become invaded by hard particles (silt) or soft particles (varnish and sludge), more force is required to move the spool. According to test data from Eaton Hydraulics, if the radial clearances of a 1/8 inch spool valve operating at 3,000 PSI silt up, 30 pounds of force is required to move the spool. But if the valve is solenoid operated, the solenoid can only exert 10 pounds of force!

This problem is commonly referred to as 'silt-lock' and can be especially problematic for valves in contaminated systems which are operated infrequently. Furthermore, if a silt-locked valve is operated by an AC solenoid, then the likely outcome is a burnt-out solenoid. This occurs because the silted spool prevents the solenoid plunger from being completely pulled into its coil. And as a result, the coil is exposed to inrush current for as long as it is energized--the heat from which it can't dissipate. This causes the insulation around the coil windings to burn and the coil eventually shorts out.

The good news is preventing silt-lock is simple enough. Keep the oil 'clean, cool and dry'. The 'clean' i.e. adequate filtration combined with the elimination of particulate ingression points will take care of the hard particles. The 'cool and dry' i.e. not letting the system run too hot and preventing the ingression of and removing water will eliminate the formation of 'soft' particles, such as varnish and sludge.

In other words, the potential for silt lock in just another reason why allowing the hydraulic oil to get and stay contaminated is a costly mistake. And to discover six other costly mistakes you want to be sure to avoid with your hydraulic equipment, get "Six Costly Mistakes Most Hydraulics Users Make... And How You Can Avoid Them!" available for FREE download here.

Continue Reading

Continue Reading

Sponsored Recommendations

Sponsored Recommendations

How Variable Volume Pumps Work

Feb. 6, 2024

What is a Check Valve and How Does it Work?

Feb. 6, 2024