This file type includes high-resolution graphics and schematics when applicable.

Several years ago, we built 10 hydraulic power units (HPUs) at our Cincinnati location for a cryogenics OEM located near Denver. The OEM builds equipment for customers that manufacture various sub-zero products along with dry ice. Part of the manufacturing process involves compressing crystallized CO2 at –109.3°F into solid blocks or pellets.

The HPUs were very simple units that would power a press’s double-acting hydraulic cylinder. The customer provided a circuit design, maximum envelope for the HPU, and noise limitation of 85 dBA to meet OSHA requirements. We specified a pressure-compensated piston pump capable of 10 gpm and electric motor mounted on top of a 30-gal reservoir.

We had a little trouble getting all of the HPU’s noise generation below the 85 dBA specification. We used an oversized intake strainer, shock mounts, and a 7EQ Delco electric motor, and labeled the minimum oil level higher than what we normally would. We swapped out a couple of the pumps with new ones on the shelf and finally got all to read under 85 dBA.

Unfortunately, the OEM rejected all of the units, claiming the noise exceeded 88 dBA. They shipped all of the HPUs back to us for rework. We tested the HPUs again using the oil originally supplied by the OEM, and they all tested at or below 85 dBA.

Any idea why the noise would be 3 dBA higher than when we tested them?

Find the Solution

Think you know the answer to this month’s problem? Submit your solution by emailing Mindy Timmer at [email protected]. All correct solutions submitted by May 2, 2016, will be entered into a random drawing for a $50 gift card. The winner will be notified, and his or her name will be printed in a future issue. Only one gift card will be awarded to any participant within a calendar year.

Solution to last month’s problem:

Cargo Ship Pressure Buildup Problem

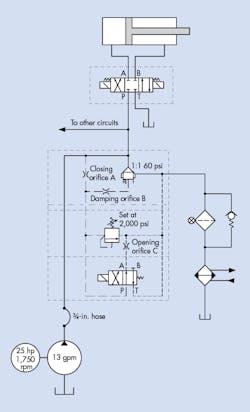

Solenoid-operated relief valves typically contain three orifices. The main pressure line flows through an orifice, A. From there, oil either leaks to the top of the main poppet, causing it to close, or drains to the tank, allowing the main poppet to open at 4 bar of pressure. This orifice normally determines the closing speed of the valve. A partial blockage in this orifice slows pressure buildup. The orifice acts like a flow control that controls the main poppet closing speed. Technicians found Teflon tape obstructing the orifice, thereby causing the delayed closing speed. Removing the obstruction solved the problem.

Congratulations to Darrick Grewe, HPCF Technical Trainer at Graco Inc., who correctly answered last month’s Troubleshooting Challenge. A $50 gift card is in the mail to him.

Looking for parts? Go to SourceESB.