ContiTech Air Spring Systems, Hannover, Germany, recently released a line of ATEX-certified air actuators, making them suitable for explosion-prone areas of industrial applications. As Category 2 and 3 equipment (Equipment Group II), they can be used in atmospheres containing volatile gas or dust. The ATEX-certified products from ContiTech are available as single-, double- and triple-convoluted actuators with diameters from 80 to 950 mm.

“The certification of our air actuator products was an important step. We can now supply our industrial customers with a safe and standardized product for explosion-prone atmospheres,” explained Dr. Olaf Kluth, segment manager at ContiTech Air Spring Systems.

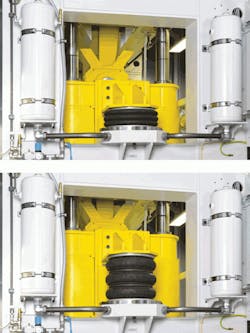

ContiTech air actuators and air springs are used in a wide range of applications, such as pressing and compressing material compounds.

Visit www.contitech-usa.com for more details.