Clogging indicators are warning devices that signal visually or electrically that a filter element is filled with contaminants and should be changed or cleaned. These indicators activate when the flow of fluid causes a pressure drop (∆P) across the filter element that exceeds a predetermined setpoint. In filters that incorporate bypass valves, contaminated fluid will flow past the element if the operator does not respond to the indicator’s signal within a reasonable time. In non-bypass filters, if the indicator warning is not heeded, the pressure across the filter will build up to the point where system performance is degraded, the element fails, or the system relief valve opens.

The indicator is set to trip well before the element becomes fully clogged — usually at about 15 psid (1 bar) lower than the bypass pressure. This gives the operator enough time to take corrective action. The indicator warning may be a visual signal at the filter site (pop-up button, light, etc.) or some form of signal at a remote location (an indicator light, audible alarm, etc.). In the most critical applications, the signal from the indicator may be used to shut down the system, which would call for immediate service from personnel.

Some users install filters without indicators, preferring instead to change or clean elements according to hours of operation. There is some risk in adopting this approach. It may be difficult to establish a reliable schedule for installing new elements because the rate of dirt ingression is not known, and, in fact, may vary with time and from machine to machine.

Clogging indicators have two primary benefits. First, they eliminate the need to guess when the element will clog. Second, they avoid the unnecessary cost of replacing elements too soon.

For most applications, we set our indicators to trip 15 psid (1 bar) below the bypass valve cracking pressure. For non-bypass filters, we set them 15 psid below the element’s replacement pressure. A Hydac pressure filter bypass valve typically begins to crack at 87 psid (6 bar), so we set the indicator to trip at 72 psid (5 bar). Our return filters normally begin to bypass at 43 psid (3 bar), so we set the indicator to trip at 29 psid (2 bar). Consequently, the operator has time to change or clean the element

before the bypass valve opens, which allows contaminated fluid to flow to components downstream of the filter.

Typically, the time from indication to bypass is 5% to 15% of the life of the element. For instance, if the element has a normal service life of 100 days, a grace period of five to 15 days occurs before the filter begins bypassing. Nevertheless, the element should be changed as soon as the indicator trips.

Non-standard indicator settings are often used for specific reasons. For instance, filters in lubrication systems may not be allowed to have a high pressure drop. Therefore, the indicator may be set to trip at less than 15 psid. When the filter is installed on the suction side of a hydraulic pump, it is normal to limit the ∆P across the filter to only 3 psid and set the indicator at a correspondingly low amount. This prevents starving the pump, which could cause cavitation.

On the other hand, some non-bypass filters are set at higher pressures. For example, Hydac’s DFDK duplex and DFZ series of sandwich filters, use indicators set at 116 psid (8 bar) in order to maximize dirt retention and service life of the elements.

In most cases, our pressure and return line filters bypass at higher pressures than other commonly used filters, meaning that indicator settings also are higher than usual. This has the advantage of extending element service life.

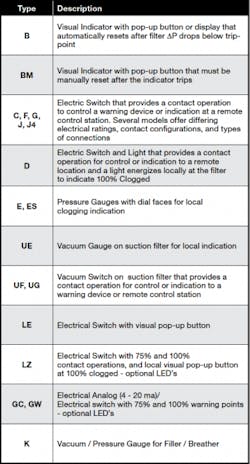

Filter assemblies may be ordered with or without indicators. When ordered with an indicator, Hydac’s assembly model code includes a letter symbol for the indicator, such as B, C, or D. Type B or BM visual indicators are suitable when only a local warning is required. To signal a remote warning device, control panel, or PLC, an electric switch should be specified. Various kinds of switches are available to provide a range of electrical configurations, contact ratings, and connections. Our Type D indicator incorporates a switch and built-in light for both local and remote warning signals.

Key features

Automatic or manual reset— All Hydac indicators with electric switches reset automatically to their original position when the pressure across the filter drops below trip pressure. This is true for our Type B visual indicator. However, on the type BM visual indicator with manual reset, the signal arm extends once the trip pressure is exceeded and remains that way until physically reset. The advantage, here, is that the indicator signals that the element is dirty even after the system is shut down, thus, simplifying maintenance.

Thermal lockout— When mobile and other equipment is started in cold weather, the hydraulic fluid is likely to be highly viscous until it approaches normal operating temperature. The high pressure drop created by a highly viscous fluid can trip the indicator and falsely signify that the element is clogged. An optional thermal lockout device, available on many of our electric indicators, prevents the indicator from tripping until the fluid reaches a certain specified temperature. The device consists of a switch in series in the indicator circuit, which is actuated by a bimetal strip that changes shape according to temperature. The thermal lockout feature may be chosen so that the indicator is deactivated at a fluid temperature less than 100˚F ±5˚. Because electric indicators automatically reset once the fluid heats up, thermal lockout is necessary only when a false signal of filter condition during cold start-up poses a problem.

SPDT switches — Hydac’s differential pressure indicators and most static pressure electrical indicators contain single-pole, double-throw (SPDT) switches. These switches come with normally open (NO) or normally closed (NC) contacts when the pressure differential is below the trip point. The choice between NO or NC contacts is determined by the requirements of control circuitry.

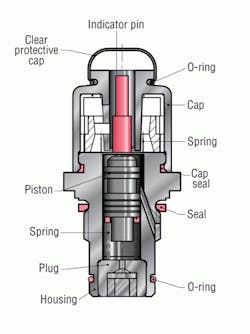

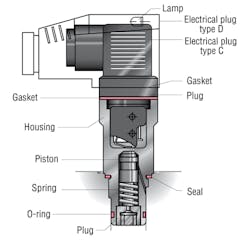

Magnetic coupling — Most of our indicators use magnetic coupling, which separates the fluid from the actuating device. The benefit is that there is no need for a dynamic seal. Therefore, far less chance exists for fluid leakage under high system pressure.

Differential pressure indicatorsreact to the pressure drop across the filter caused by the flow of fluid through the filter housing and element. They do this by sensing the difference in pressure upstream and downstream of the filter element, regardless of the system pressure. They are used in most pressure and in-line return filters.

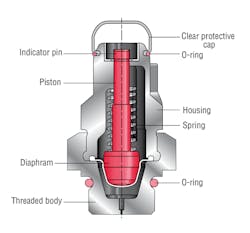

Static pressure indicatorsmeasure only the buildup of pressure upstream of the filter element (downstream pressure is ambient — tank vented to atmosphere). Consequently, if any components are located downstream of the filter, the indicator will measure the pressure drop caused by the filter and that component, thus causing a false reading of ∆P across the filter. As a result, static indicators are recommended only on filters that discharge directly to vented tanks and have minimal backpressure.

A filter that incorporates a differential pressure indicator should be used whenever there is a significant resistance to flow in the line after the filter, even when system pressure is relatively low. For example, the filter in the feed line of a lubrication system requires a differential pressure indicator, although the system pressure may be low.

As the differential pressure across a filter increases, a piston-magnet assembly is driven down against a spring until the attractive force between the magnet and indicator pin (Type 1) or a switch actuator lever (Type 2) is reduced sufficiently to allow the indicator to trip. In a visual indicator (Type 1), tripping results in the indicator pin rising and giving visual indication that the filter must be serviced. In an electric indicator (Type 2), tripping causes a switch to make or break, permitting a remote indication to warn of the need for servicing. When the ∆P drops below the trip pressure for any reason, (installation of a clean element, heating of the oil, etc.), the piston/ magnet assembly returns to its original position.

With a visual indicator, the pop-up pin may then respond in one of two ways. With manual reset, the signal pin remains extended, even after the system is shut down, and must be physically pushed down to be reset. With automatic resetthe signal pin reverts back to its original position along with the piston. With electric indicators, the circuit is automatically restored to its original normally closed or normally open position once the differential pressure drops below the trip setting.

Static pressure indicators

With static pressure indicators, increasing pressure upstream of the filter acts on a diaphragm in the indicator (Type 3) and causes the signal pin to overcome an opposing spring force until it trips at a pre-set pressure. The indicator pin automatically resets once pressure is reduced below the trip pressure. Electric static pressure

indicators, which also operate mechanically, are available as well. These, too, reset auto-

matically.

Jeff Ruth is product manager - industrial filtration at HYDAC Technology Corp., Bethlehem, Pa. For more information, visit www.hydacusa.com. Click here to download a PDF brochure describing HYDAC’s filter clogging indicators.