Government regulations aimed at protecting the environment are a fact of life that everyone who designs, builds, or uses hydraulic systems is either dealing with now, or soon will be. At least 700 million gallons of petroleum-based fluids enter the environment annually, more than half through illegal disposal channels and somewhere between 70 and 80% of all hydraulic fluids leave the system through leaks, line ruptures, and spills.

Environmental officials around the world have launched a broad range of green initiatives backed up by significant fines and clean-up cost allocations aimed at the whole user community. Fluid suppliers have responded by introducing new, eco-friendly biodegradable and non-toxic fluids based on a variety of different chemistries.

Unfortunately, none of these fluids are a direct one-for-one replacement for the petroleum-based fluids the hydraulics industry has grown up with over the last century, so previous experience is no guarantee of future success. The situation is complicated by economic pressures that are moving the industry toward higher operating pressures, temperatures, and working cycles — all of which are more efficient but also increase the stress on components and lubricants.

Defining biodegradable and non-toxic

Biodegradation is the process of chemical breakdown or transformation of a substance caused by organisms or enzymes. Two common measures of degradation are complete (technically, ultimate degradation), in which the only end products are carbon dioxide, water, and any indigestible inorganic elements. Incomplete degradation (technically, primary degradation) is measured by the reduction of hydrocarbons in the original solution. The relevant test standards are OECD 301 or ASTM D5864 for ultimate degradation and CEC-L-33-A-93 for primary degradation.

Two other terms in common use are readily and inherently biodegradable. A readily biodegradable fluid will undergo primary degradation greater than 80% within 21 days or ultimate degradation greater than 60% within 28 days. Inherently biodegradable fluids break down slowly over time, usually measured in years, and cause substantial damage to the environment.

Eco-toxicity is a measurement of the concentration required to kill various organisms over a short period of time — ranging from 24 to 96 hr. The toxicity of a fluid is described by a loading rate in parts per million (ppm) of fluid that has a 50% effect or causes 50% mortality of the organisms after the stated time.

The important thing to remember is that both biodegradability and non-toxicity are relative terms. Environmental friendliness absolutely does not mean the fluid is totally harmless to the environment and/or living things, only that it is less harmful than something else. Environmentally friendly or green fluids absolutely must be disposed of carefully and responsibly.

Finding a green alternative to petroleum

Four basic types of environmentally-friendly hydraulic fluids are in common use:

• HETG — hydraulic environmental triglyceride (water insoluble triglycerides),

• HEES — hydraulic environmental ester synthetic (water insoluble synthetic ester),

• HEPG — hydraulic environmental poly glycol (water soluble poly alkylene glycol [PAG]), and

• HEPR — hydraulic environmental polyalphaolefin and related fluids (water insoluble poly alpha olefins [PAO] and related hydrocarbon-based fluids).

Each of these chemistries is best applied to a specific range of application categories and operating conditions. They also have different interactions with seal materials and other system components. These interactions need to be taken into account when weighing considerations about whether or not they will be a suitable replacement for petroleum based fluids in any particular hydraulic system.

HETG fluid characteristics

Triglycerides are long-chain fatty acids combined with alcohol in the form of glycerin. Natural triglycerides have excellent lubricity but poor thermal and hydrolytic stability. They also oxidize rapidly. Hydrolytic stability and oxidation resistance can be improved with additives, chemical modification, and even genetic modification of the seeds used to produce the base stock.

HETG fluids offer many advantages. For one, they are highly biodegradable and non-toxic. They offer excellent lubricity and anti-corrosion properties. And because they are made from natural, renewable resources, they are available in plentiful supply. In addition, they have a high viscosity index and high flash point.

Of course, HETG fluids have some drawbacks. They are adversely impacted by high temperature operation, which causes quick aging, rapid oxidation, and extreme thickening and gumming. In addition, they are susceptible to water contamination, which causes hydrolysis and TAN increases. They tend to thicken and gel because they do not perform well at low temperature. Finally, they are double the cost of mineral oils; they require special system designs; and because they are miscible with mineral oil, this can have a negative effect on biodegradability.

HEES fluid characteristics

HEES fluids are synthetic esters that are derived from either petroleum or vegetable — typically rapeseed— oil feedstocks. Petroleum sourced HEES fluids are a combination of an organic acid and alcohol, whereas the vegetable sourced fluids are a combination of a fatty acid and alcohol.

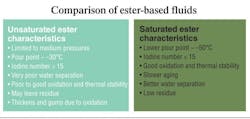

HEES fluids are available as unsaturated, partially saturated, and fully saturated products. Of these, the fully saturated products generally offer the best performance and command the highest price.

HETG and HEES fluids are often considered for the same applications, so the chart on page 38 is intended to provide a quick comparison of their major characteristics.

HEPG fluid characteristics

HEPG fluids are polymers made from the reaction of such alkylene oxide monomers as ethylene oxide, propylene glycol, or propylene oxide with glycol. Those with 50 to 100% ethylene oxide are water soluble, while those with 100% propylene oxide are water insoluble. Both types have inherent fire-resistant characteristics.

The biodegradability of HEPG fluids depends on the ratio of propylene to ethylene oxides. The higher the molecular weight, the lower the biodegradability of the fluid.

HEPG fluids are offered in a very broad viscosity range. They have many fire-resistant characteristics and have an operating temperature range limited to –20° to 80°C. In addition, water soluble polyglycols can be used as anhydrous lubricants.

However, they, too, require special system designs, and they are incompatible with polyurethane seals. Finally, pumps and motors may need to be de-rated when used with HEPG fluids.

HEPR fluid characteristics

HEPR fluids are synthetic hydrocarbons manufactured by the polymerization of alpha olefins to produce polyalphaolefins (PAO). Only the low viscosity PAOs are considered environmentally friendly.

A key advantage of HEPR fluids is that they offer excellent oxidation stability and good corrosion protection. They also have good lubricity, aging characteristics, and have a long service life. Offering a very good viscosity/temperature performance, they have a pour point of –20° to –40°C and operating temperature range of –30° to 100°C.

However, like most green fluids, they have a high cost. They are also incompatible with many seal and gasket materials and have a high density compared to mineral oil.

What to know before switching

1. Seal Compatibility

Traditional nitrile seals will fail quickly when used with many environmentally friendly hydraulic fluids. In general, the best results will be achieved with fluorocarbon seal materials.

In any case, the fluid supplier, equipment manufacturer, and seal supplier all should be consulted before converting any system to an environmentally friendly fluid. The same is true for gaskets used in the system.

2. System flushing

Although traditional petroleum based fluids will mix readily with environmentally friendly fluids, this should be avoided because the petroleum contamination will nullify the biodegradability and toxicity benefits of the green product. Very thorough system flushing is necessary, and it is often advisable to perform multiple flushes to ensure the system is perfectly clean before adding the environmentally friendly fluid.

Note, especially, that engine oil additives are not compatible with environmentally friendly fluids. Equipment that has been operated with engine oil as a hydraulic fluid requires an exceptionally thorough cleaning before the environmentally friendly fluid is installed.

Furthermore, virtually all hydraulic components are tested with petroleum-based fluids. Any new component being installed on a system using environmentally friendly fluids must be thoroughly flushed prior to installation to avoid contamination.

3. Maintenance

Filtration requirements are generally the same for petroleum based and environmentally friendly fluids in terms of particle sizes. Filter change intervals may be different, however, particularly with HETG fluids that have shorter service lives and a tendency to produce varnish and other contaminants. Size filters generously.

Note also that most environmentally friendly fluids have a higher specific gravity than traditional petroleum based fluids. This may require adjusting inlet conditions to maintain adequate suction and avoid cavitation.

4. Disposal practices

As noted at the beginning of this article, the terms “biodegradable” and “non-toxic” do not mean that fluids labeled as such are harmless to the environment. They must be disposed of properly.

Spills of “environmentally friendly” fluids are still reportable incidents, but many environmental regulatory agencies are required to treat them differently from spills of petroleum-based fluids. Because environmentally friendly fluids are less toxic and more biodegradable, cleanup and reclamation costs may be lower. For example, the affected soil often does not have to be dug up and autoclaved, as is the case in most petroleum based spills. And operations are frequently allowed to continue during the cleanup.

Caution and prevention key

In summary, environmentally friendly hydraulic fluids are not a substitute for regular maintenance and good operating practices. Prevention is still much more cost effective than remediation when it comes to the environmental impact of your operations.

What they offer is a less toxic alternative to petroleum-based fluids that is more easily assimilated by the environment when properly disposed off, and causes less damage when introduced by accident. The price for the additional safety they offer is often measured in higher initial cost, shorter service life, reduced efficiency, and increased maintenance requirements.

Each of the potential negative impacts can be minimized through careful planning to select the fluid that best matches your application requirements. It’s probably a good idea to get started down that path soon, because the time is rapidly approaching when you may no longer have a choice.

Contact Thelma Marougy at (248) 226-6985 or [email protected].

For more on environmentally friendly fluids, visit the following links, which contain technical articles, more on the basics and fundamentals of green and bio-based fluids, and new products in the marketplace:

www.hydraulicspneumatics.com/environmental-fluids

www.hydraulicspneumatics.com/bio-based-fluids

www.hydraulicspneumatics.com/water-based-fluids