When officials at Rig Source Inc., Elburn, Ill., decided to develop a new tracked carrier, they knew it had to be versatile. According to Mike Crimaldi, president of Rig Source, other carriers, especially those from offshore suppliers, either come loaded with features and capabilities that customers don’t need, or they come in a basic, stripped down model. Either way, equipment owners don’t want to pay for options they won’t use or wait for a basic model to be built up.

Rig Source recently introduced its Terramac RT9, which uses the versatility of hydraulics to make it quickly adaptable to different applications. One standard model comes with a dump bed, but if users want to use it in a mining application, the RT9 gets a flat bed, water tank, and hydraulic crane to handle drill sections. Power for the crane comes from the gear pump that would’ve powered the dump bed. Crimaldi said, “We created the RT9 with customization as a top priority. The ability to mount a variety of machines is the RT9’s core differentiation and strength.”

The RT9 has a standard carrying capacity of 18,000 lb (8165 kg). However, it is also light on its feet, exerting only 4.9 psi (0.34 kg/cm2) of ground pressure and with a 10 ft (3-m) turning radius.

Hydraulics take the lead

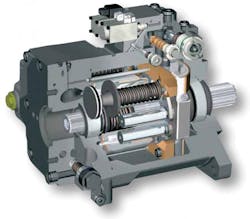

The RT9 runs on a pair of rubber tracks driven by a hydrostatic transmission (HST). The HST is powered by a pair of Eaton Duraforce variable-displacement axial-piston pumps (one for the left track, one for the right), each capable of delivering up to 195 lpm (43 gpm) at 386 bar (5600 psi).

Eaton’s pumps in this line are available in seven standard sizes. Their modular design allows incorporating hydraulic and electronic control features to match them to a wide variety of applications.

Each HST pump powers a Brevini dual-displacement bent-axis hydraulic motor. These motors were chosen, in part, for their wide displacement range of 5:1 and high power-to-weight ratio. They are rated for continuous pressure of 430 (6235 psig) bar and peak of 480 bar (6960 psi). Their 28º bent-axis angle eliminates the need for a joint linking the barrel with the output shaft. Each motor can drive the track at 4 km/hr (2.5 mph) in its low-speed high-torque setting or 10 km/hr (6 mph) in high speed.

The HST pumps are mounted in tandem to a Cummins 6.7 l (409 in.3) diesel engine that delivers 172 kW (230 hp) of power. Tandem mounted to the rear HST pump are two gear pumps. The first is a charge pump that delivers 20 gpm (75 lpm) at 500 psi (34 bar). The charge pump not only supplies the hydrostatic pumps with pressurized fluid, but also provides pressurized fluid to disengage spring-applied, pressure released brakes on the motors. The charge pump also supplies pilot fluid to shift the two-speed motors.

Tandem mounted to the back of the charge pump is a gear pump for auxiliary hydraulics — dump bed, crane, or whatever implement the customer needs. The standard auxiliary pump delivers 25 gpm (95 lpm) at 2500 psi (172 bar).

But as if this isn’t enough, a second auxiliary hydraulic pump can be powered from a flange on the Cummins engine to deliver an additional 25 gpm (95 lpm) at 2500 psi (172 bar).

Simple, yet sophisticated

Even though the RT9 offers simplicity and versatility in its design, it uses electronic controls for efficient and productive operation. The engine speed is controlled by the operator via a hand throttle on the dash. Two armrest mounted joysticks on the right hand side of the seat control displacement of hydrostatic pumps electronically — thereby controlling how much oil flow is sent to the drive motors.

Each joystick provides proportional control of one track. It is a simple system using a pair of joysticks so the operator to can quickly andf easily maneuver the carrier around a work site.

For more information on the RT9 visit www.terramac.com. For details on Eaton’s Duraforce HPV pumps,click here. See the Terramac RT9 at MINExpo booth 5501.