All types of hydraulic motors have common design features: a driving surface area subject to pressure differential; a way of timing the porting of pressure fluid to the pressure surface to achieve continuous rotation; and a mechanical connection between the surface area and an output shaft.

The ability of the pressure surfaces to withstand force, the leakage characteristics of each type of motor, and the efficiency of the method used to link the pressure surface and the output shaft determine the maximum performance of a motor in terms of pressure, flow, torque output, speed, volumetric and mechanical efficiencies, service life, and physical configuration.

Terminology

Motor displacement refers to the volume of fluid required to turn the motor output shaft through one revolution. The most common units of motor displacement are in.3 or cm3 per revolution. Hydraulic motor displacement may be fixed or variable. A fixed-displacement motor provides constant torque. Controlling the amount of input flow into the motor varies the speed. A variable-displacement motor provides variable torque and variable speed. With input flow and pressure constant, varying the displacement can vary the torque speed ratio to meet load requirements.

Torque output is expressed in inch-pounds or foot-pounds. It is a function of system pressure and motor displacement. Motor torque ratings usually are given for a specific pressure drop across the motor. Theoretical figures indicate the torque available at the motor shaft, assuming no mechanical losses.

Breakaway torque is the torque required to get a stationary load turning. More torque is required to start a load moving than to keep it moving.

Running torque can refer to a motor’s load or to the motor. When it refers to a load, it indicates the torque required to keep the load turning. When it refers to the motor, it indicates the actual torque that a motor can develop to keep a load turning. Running torque considers a motor’s inefficiency and is a percentage of its theoretical torque. The running torque of common gear, vane, and piston motors is approximately 90% of theoretical.

Starting torque refers to the capacity of a hydraulic motor to start a load. It indicates the amount of torque that a motor can develop to start a load turning. In some cases, this is considerably less than the motor’s running torque. Starting torque also can be expressed as a percentage of theoretical torque. Starting torque for common gear, vane, and piston motors ranges between 70% and 80% of theoretical.

Mechanical efficiency is the ratio of actual torque delivered to theoretical torque.

Torque ripple is the difference between minimum and maximum torque delivered at a given pressure during one revolution of the motor.

Motor speed is a function of motor displacement and the volume of fluid delivered to the motor.

Maximum motor speed is the speed at a specific inlet pressure that the motor can sustain for a limited time without damage.

Minimum motor speed is the slowest, continuous, uninterrupted rotational speed available from the motor output shaft.

Slippage is the leakage through the motor, or the fluid that passes through the motor without performing work.

Gear motors

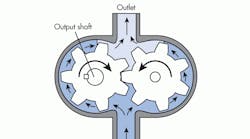

Figure 1. The output torque of an external gear motor is a function of pressure on one tooth because pressure on other teeth is in hydraulic balance.

External gear motors consist of a pair of matched gears enclosed in one housing (Fig. 1). Both gears have the same tooth form and are driven by pressure fluid. One gear is connected to an output shaft. The other is an idler. Pressure fluid enters the housing at a point where the gears mesh. It forces the gears to rotate and follows the path of least resistance around the periphery of the housing. The fluid exits at low pressure at the opposite side of the motor. Close tolerances between gears and housing help control fluid leakage and increase volumetric efficiency. Wear plates on the sides of the gears keep the gears from moving axially and help control leakage.

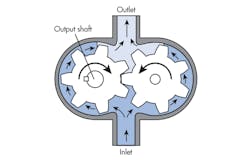

Figure 2. A direct-drive gerotor motor has internal and external gear sets. Both gears rotate during operation.

Internal gear motors fall into two categories. A direct-drive gerotor motor consists of an inner-outer gear set and an output shaft (Fig. 2). The inner gear has one fewer tooth than the outer. The teeth are shaped so all of the teeth of the inner gear are in contact with some portion of the outer gear at all times. When pressure fluid is introduced into the motor, both gears rotate. The motor housing has integral kidney-shaped inlet and outlet ports. The centers of rotation of the two gears are separated by a given amount known as the eccentricity. The center of the inner gear coincides with the center of the output shaft.

Pressure fluid enters the motor through the inlet port (Fig. 2a). Because the inner gear has one fewer tooth than the outer, a pocket is formed between inner teeth 6 and 1 and outer socket A. The kidney-shaped inlet port is designed so that just as this pocket’s volume reaches its maximum, fluid flow is shut off, with the tips of inner gear teeth 6 and 1 providing a seal (Fig. 2b).

As the pair of inner and outer gears continues to rotate, a new pocket is formed between inner teeth 6 and 5 and outer socket G (Fig. 2c). Meanwhile, the pocket formed between inner teeth 6 and 1 and outer socket A has moved around opposite the kidney-shaped outlet port, steadily draining as the volume of the pocket decreases. The gradual, metered volume change of the pockets during inlet and exhaust provides smooth, uniform fluid flow with a minimum of pressure variation (or ripple).

Because of the extra tooth in the outer gear, the inner gear teeth move ahead of the outer by one tooth per revolution. In Figure 2c, inner tooth 4 is seated in outer socket E. On the next cycle, inner tooth 4 will seat in outer socket F. This produces a low relative differential speed between the gears.

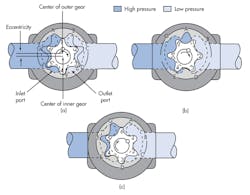

Figure 3. An orbiting gerotor motor has a stationary outer gear and a rotating inner gear. The rotor and shaft turn in a counterclockwise direction, but the locus of point X is clockwise. The commutator or valve plate, shown below the illustration of each stage of motor rotation, provides pressure and tank passage for pressure fluid.

An orbiting gerotor motor consists of a set of matched gears, a coupling, an output shaft, and a commutator or valve plate (Fig. 3). The stationary outer gear has one more tooth than the rotating inner gear. The commutator turns at the same rate as the inner gear and always provides pressure fluid and a passageway to tank to the proper spaces between the two gears.

In operation, tooth 1 of the inner gear is aligned exactly in socket D of the outer gear (Fig. 3a). Point y is the center of the stationary gear, and point x is the center of the rotor. If there were no fluid, the rotor would be free to pivot about socket D in either direction. It could move toward seating tooth 2 in socket E or, conversely, toward seating tooth 6 in socket J.

When pressure fluid flows into the lower half of the volume between the inner and outer gears, if a passageway to tank is provided for the upper-half volume between the inner and outer gears, a moment is induced that rotates the inner gear counterclockwise and starts to seat tooth 2 in socket E. Tooth 4, at the instant shown in Figure 3a, provides a seal between pressure and return fluid.

However, as rotation continues, the locus of point x is clockwise. As each succeeding tooth of the rotor seats in its socket, the tooth directly opposite on the rotor from the seated tooth becomes the seal between pressure and return fluid (Fig. 3b). The pressurized fluid continues to force the rotor to mesh in a clockwise direction while it turns counterclockwise.

Because of the one extra socket in the fixed gear, the next time tooth 1 seats, it will be in socket J. At that point, the shaft has turned one-seventh of a revolution, and point x has moved six-sevenths of its full circle. In Figure 3c, tooth 2 has mated with socket D, and point x has again become aligned between socket D and point y, indicating that the rotor has made one full revolution inside of the outer gear. Tooth 1 has moved through an angle of 60° from its original point in Figure 3a; 42 (or 627) tooth engagements or fluid cycles would be needed for the shaft to complete one revolution.

The commutator or valve plate contains pressure and tank passages for each tooth of the rotor (Fig. 3d, e, and f). The passages are spaced so they do not provide for pressure or return flow to the appropriate port as a tooth seats in its socket. At all other times, the passages are blocked or are providing pressure fluid or a tank passage in the appropriate half of the motor between gears.

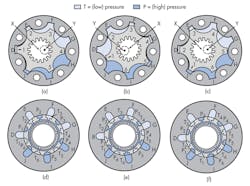

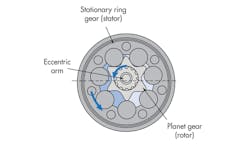

Figure 4. A roller-vane gerotor motor incorporates rolling vanes that reduce wear.

A roller-vane gerotor motor is a variation of the orbiting gerotor motor (Fig. 4). It has a stationary ring gear (or stator) and a moving planet gear (or rotor). Instead of being held by two journal bearings, the eccentric arm of the planetary is held by the meshing of the six-tooth rotor and seven-socket stator. Instead of direct contact between the stator and rotor, roller vanes are incorporated to form the displacement chambers. The roller vanes reduce wear, enabling the motors to be used in closed-loop, high-pressure hydrostatic circuits as direct-mounted wheel drives.

Vane Motors

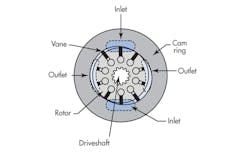

Figure 5. Vane motors (balanced type shown) have vanes in a slotted rotor.

Vane motors have a slotted rotor mounted on a driveshaft that is driven by the rotor (Fig. 5). Vanes, closely fitted into the rotor slots, move radially to seal against the cam ring. The ring has two major and two minor radial sections joined by transitional sections or ramps. These contours and the pressures introduced to them are balanced diametrically.

In some designs, light springs force the vanes radially against the cam contour to ensure a seal at zero speed so the motor can develop starting torque. The springs are assisted by centrifugal force at higher speeds. Radial grooves and holes through the vanes equalize radial hydraulic forces on the vanes at all times.

Pressure fluid enters and leaves the motor housing through openings in the side plates at the ramps. Pressure fluid entering at the inlet ports moves the rotor counterclockwise. The rotor transports the fluid to the ramp openings at the outlet ports to return to tank. If pressure were introduced at the outlet ports, it would turn the motor clockwise.

The rotor is separated axially from the side plate surfaces by the fluid film. The front side plate is clamped against the cam ring by pressure and maintains optimum clearances as temperature and pressure change dimensions.

Vane motors provide good operating efficiencies, but not as high as those of piston motors. However, vane motors generally cost less than piston motors of corresponding horsepower ratings. The service life of a vane motor usually is shorter than that of a piston motor, though. Vane motors are available with displacements of 20 in.3/rev. Some low-speed/high-torque models come with displacements to 756 in.3/rev. Except for the high-displacement, low-speed models, vane motors have limited low-speed capability.

Piston-Type Motors

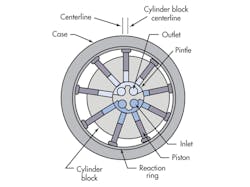

Figure 6. Radial-piston motors have a cylinder barrel attached to a driven shaft. The barrel contains a number of pistons that reciprocate in radial bores.

Radial-piston motors have a cylinder barrel attached to a driven shaft (Fig. 6). The barrel contains a number of pistons that reciprocate in radial bores. The outer piston ends bear against a thrust ring. Pressure fluid flows through a pintle in the center of the cylinder barrel to drive the pistons outward. The pistons push against the thrust ring and the reaction forces rotate the barrel.

Shifting the slide block laterally to change the piston stroke varies motor displacement. When the centerlines of the cylinder barrel and housing coincide, there is no fluid flow and therefore the cylinder barrel stops. Moving the slide past center reverses the direction of motor rotation.

Radial piston motors are very efficient. Although the high degree of precision required in the manufacture of radial piston motors raises initial costs, they generally have a long life. They provide high torque at relatively low shaft speeds and excellent low-speed operation with high efficiency. Also, they have limited high-speed capabilities. Radial piston motors have displacements to 1,000 in.3/rev.

Axial-piston motors also use the reciprocating piston motion principle to rotate the output shaft, but motion is axial, rather than radial. Their efficiency characteristics are similar to those of radial-piston motors. Initially, axial-piston motors cost more than vane or gear motors of comparable horsepower. Like radial piston motors, they also have a long operating life. Consequently, their higher initial cost may not truly reflect the expected overall costs during the life of a piece of equipment.

In general, axial piston motors have excellent high-speed capabilities. Unlike radial piston motors, though, they are limited at low operating speeds. The inline type will operate smoothly down to 100 rpm, and the bent-axis type will provide smooth output down to the 4-rpm range. Axial piston motors are available with displacements from a fraction to 65 in.3/rev.

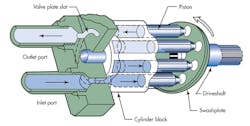

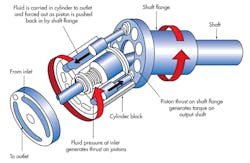

Figure 7. Inline-piston motors generate torque through pressure exerted on the ends of pistons that reciprocate in a cylinder block. The motor driveshaft and cylinder block are centered on the same axis.

Inline-piston motors generate torque through pressure exerted on the ends of pistons that reciprocate in a cylinder block (Fig. 7). In the inline design, the motor driveshaft and cylinder block are centered on the same axis. Pressure at the ends of the pistons causes a reaction against a tilted swashplate and rotates the cylinder block and motor shaft. Torque is proportional to the area of the pistons and is a function of the angle at which the swashplate is positioned.

These motors are built in fixed- and variable-displacement models. The swashplate angle determines motor displacement. In the variable model, the swashplate is mounted in a swinging yoke, and the angle can be changed by various means, ranging from a simple lever or hand-wheel to sophisticated servo controls. Increasing the swashplate angle increases the torque capacity but reduces driveshaft speed. Conversely, reducing the angle reduces the torque capacity but increases driveshaft speeds (unless fluid pressure decreases). Angle stops are included so torque and speed stay within operating limits.

A compensator varies motor displacement in response to changes in the workload. A spring-loaded piston is connected to the yoke and moves it in response to variations in operating pressure. Any load increase is accompanied by a corresponding pressure increase as a result of the additional torque requirements. The control then automatically adjusts the yoke so torque increases when the load is light. Ideally, the compensator regulates displacement for maximum performance under all load conditions up to the relief valve setting.

Figure 8. Bent-axis piston motors develop torque through a reaction to pressure on reciprocating pistons. The cylinder block and driveshaft are mounted at an angle to each other. The reaction is against the driveshaft flange.

Bent-axis piston motors develop torque through a reaction to pressure on reciprocating pistons (Fig. 8). In this design, the cylinder block and driveshaft are mounted at an angle to each other. The reaction is against the drive-shaft flange.

Speed and torque change with changes in the angle, from a predetermined minimum speed with a maximum displacement and torque at an angle of approximately 30Ë to a maximum speed with minimum displacement and torque at about 7.5Ë. Both fixed- and variable-displacement models are available.

Other Designs

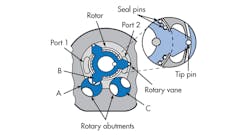

Rotary abutment motors have abutment A, which rotates to pass rotary vane B, while second abutment C is in alternate sealing engagement with the rotor hub (Fig. 9). Torque is transmitted directly from the fluid to the rotor and from the rotor to the shaft. Timing gears between the output shaft and rotary abutments keep the rotor vane and abutments in the proper phase. A roller in a dovetail groove at the tip of the rotor vane provides a positive seal that is essentially frictionless and relatively insensitive to wear. Sealing forces are high and friction losses are low because of rolling contact.

Figure 9. Abutment A of rotary abutment motor turns past rotary vane B, while second abutment C contacts the seal plate to separate high- and low-pressure areas. Sealing pins in vane tips and rotor periphery provides nearly frictionless seal. The rotor will turn clockwise with pressure fluid applied to port 1.

A screw motor essentially is a pump with the direction of fluid flow reversed. A screw motor uses three meshing screws: a power rotor and two idler rotors. The idler rotors act as seals that form consecutive isolated helical chambers within a close-fitting rotor housing. Differential pressure acting on the thread areas of the screw set develops motor torque.

The idler rotors float in their bores. The rotary speed of the screw set and fluid viscosity generates a hydrodynamic film that supports the idler rotors, much like a shaft in a journal bearing to permit high-speed operation. The rolling screw set provides quiet, vibration-free operation.

Selecting a Hydraulic Motor

The application of the hydraulic motor generally dictates the required horsepower and motor speed range, although the actual speed and torque required may sometimes be varied while maintaining the required horsepower. The type of motor selected depends on the required reliability, life, and performance.

Once the type of fluid is determined, the selection of actual size is based on the expected life and the economics of the overall installation on the machine. A fluid motor operating at less than rated capacity will provide a service life extension more than proportional to the reduction in operation below the rated capacity.

The maximum horsepower produced by a motor is reached when operating at the maximum system pressure and at the maximum shaft speed. If the motor is always to be operated under these conditions, its initial cost will be lowest. But where output speed must be reduced, the overall cost of the motor with speed reduction must be considered to optimize the overall drive installation costs.

Sizing a Hydraulic Motor

As an example of how to calculate hydraulic motor size to match an application, consider the following: an application calls for 5 hp at 3,000 rpm, with an available supply pressure of 3,000 psi and a return line pressure of 100 psi; the pressure differential is 2,900 psi. The theoretical torque required is calculated from:

T = (63,0252 × hp)/N

where:

T is torque, lb-in., and

N is speed, rpm.

For the condition T = 105 lb-in., motor displacement is calculated as:

D = 2π T ÷ âPeM

where:

D is displacement, in.3/rev

âP is pressure differential, psi, and

eM is mechanical efficiency, %.

If mechanical efficiency is 88%, then D is 0.258 in.3/rev.

Calculating the required flow:

Q = DN/231eV,

where:

Q is flow, gpm, and

eV is volumetric efficiency, %.

If volumetric efficiency is 93%, then Q is 3.6 gpm.

Pressure in these equations is the difference between inlet and outlet pressure. Thus, any pressure at the outlet port reduces the torque output of a fluid motor.

The efficiency factor for most motors will be fairly constant when operating from half- to full-rated pressure and over the middle portion of the rated speed range. As speed nears either extreme, efficiency decreases.

Lower operating pressures result in lower overall efficiencies because of fixed internal rotating losses that are characteristic of any fluid motor. Reducing displacement from maximum in variable-displacement motors also reduces the overall efficiency.

Hydraulic Motor Malfunctions

Most motor problems are caused by improper fluid, poor maintenance, or improper operation. The motor is no different than any of the other components of the hydraulic system. Primarily, it must have clean fluid, in adequate supply, and of the proper quality and viscosity. A poor maintenance program runs a close second in causing major problems. Typical slips in a program include:

• Failure to check and repair lines and connections to stop leaks: faulty connections can allow dirt and air into the system, lower pressure, and cause erratic operation.

• Failure to install the motor correctly: Motor shaft misalignment can cause bearing wear, which can lead to lost efficiency. A misaligned shaft also can reduce the torque, increase friction drag and heating, and result in shaft failure.

• Failure to find the cause of a motor malfunction: If a motor fails, always look for the cause of the failure. Obviously, if the cause is not corrected, failure will recur.

Finally, exceeding a motor’s operating limits promotes motor failure. Every motor has design limitations on pressure, speed, torque, displacement, load, and temperature.ï Excessive pressure can generate heat because of motor slippage and cause the motor to exceed torque limits.ï Excessive speed can heat and wear bearings and other internal parts.ï Excessive torque can cause fatigue and stress to bearings and the motor shaft, especially on applications that require frequent motor reversing. Excessive load can create bearing and shaft fatigue. And, excessive temperature can decrease efficiency because the oil becomes thinner and can produce rapid wear because of lack of lubrication.