This file type includes high-resolution graphics and schematics when applicable.

Most energy-saving vehicles (especially those with hybrid drives) within the automotive arena have adopted the automated start-stop system as standard. Depending on the driving cycle, it’s possible to reduce fuel consumption 2% to 6% when the engine automatically shuts off at traffic lights or during congested traffic. However, such a system might also dramatically reduce fuel consumption in agricultural and other machines that often operate intermittently.

A diesel engine running continuously wastes fuel and generates a lot of noise. To address these issues, we went about examining how agriculturally related diesel engines, such as those used in wheel loaders, could be switched off and restarted. We tackled the problem by developing a new type of hydraulic start-stop system.

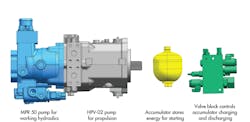

The automated start-stop system is based on Linde’s MPR 50 variable-displacement piston pump, which displaces up to 50 cc/rev and has an integral charge pump and electrohydraulic position feedback. The MPR 50 supplies oil to the hydraulic work functions but also performs another task in the start-stop application. When the diesel engine is running, the pump also charges an accumulator to store energy. The accumulator then provides hydraulic power to restart the engine by routing fluid back to the pump, which now acts as a starter motor. The diesel engine also powers a Linde HPV 02 variable-displacement axial-piston pump for the vehicle’s propulsion drive.

Shutting down engine conserves fuel

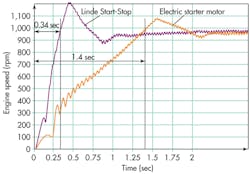

When the Linde LINC electronic-control unit detects that the driving and working functions have come to a standstill, it shuts off the diesel engine. If the operator touches the equipment’s accelerator pedal or moves the steering wheel or joystick, power is fed from the accumulator, via a valve block, back to the MPR pump. The pump thus functions as a starter motor, and the diesel engine subsequently ramps up to a predetermined speed. A hydraulic motor starts diesel engines four times quicker than an electric starter motor typically does, ensuring that the machine is ready for operation without any noticeable delay.

We used a telehandler for fuel-consumption testing. Two key factors were in play. First, power consumption rose whenever the accumulator was being charged. When using the control system, the increased consumption can be linked to, say, a lifting operation with an increase in engine speed. Second, the diesel engine’s consumption when idling must be considered to calculate the overall efficiency. We examined the relationship between these two factors and determined that after just 2.5 sec, the consumption advantage gained by switching off the diesel engine exceeds the energy required to restart it. The system should reduce fuel consumption by about 450 liters per year for the forklift in a typical scenario. This figure is based on a 50 kW diesel engine operating 1,000 hr/yr, idling 30% of the time, and consuming 1.5 l of fuel per hr while idling. Of course, overall fuel consumption depends on the type of machine, individual usage, and duration of work stoppages.

The system is compact, and the hydraulic accumulator and the start-stop valve block can be placed in any of several convenient locations within the machine. As a result, a start-stop function can be easily retrofitted into or removed from machines with hydraulic working functions, and usually without the need for any design modifications.

Beyond its ability to lower fuel costs and reduce exhaust emissions, the start-stop function also reduces noise. The start-stop system isn’t restricted just to forklift trucks or agricultural machines. Its reduced fuel consumption and noise could be practical for a wide variety of mobile hydraulic machines that undergo regular idle periods or have intermittent working patterns.

Christian Bischof is Director of Marketing & Corporate Communications at Linde Hydraulics, Aschaffenburg, Germany. For more information call (330) 533-6801, or visit www.linde-hydraulics.com.