Unfortunately, there is no reliable system for accurately determining the expected service life of a hydraulic pump. Historical data is one of the most reliable indicators. But if the hydraulic system is new, you don’t have any data! The good news is that several factors influence pump life. Considered together, they can be used to develop an informed estimate.

This file type includes high resolution graphics and schematics when applicable.

Consider the hydraulic system of a current generation, semi-submersible drilling rig. The power unit comprises a 10,000-liter tank supplying five Rexroth A4VSO250DP/30R pumps with flooded inlets. These pumps power, on a ring main, the top drive, hydraulic derrick, iron roughneck, and other ancillary equipment for the drilling rig itself. The system has a normal operating temperature of 43°C and no suction strainers. It also has pressure and return line filtration, the oil is prefiltered to ISO 4406 17/15/12, and its condition is monitored monthly.

First, consider what we know about the pump itself. The A4VSO is an industrial-grade, axial-piston model. “Industrial grade” means it is designed and built for long life, which, admittedly, can be relative. Also, its axial-piston design means its shaft bearings aren’t heavily loaded and, therefore, aren’t at high risk of premature failure (see “Preventing Hydraulic Failures”).

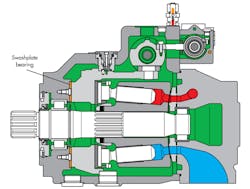

Roller-type, swashplate bearings in axial-piston designs are prone to premature failure caused by brinelling. But in the A4VO pump, the swashplate bearings are shell-type (more like a bushing than a bearing). Potential brinelling (and subsequent failure) of the swashplate bearings, then, is not an issue (see the figure).

Based on my experience and knowledge of this model pump, I’d look for a service life of between 10,000 and 20,000 hr. But this is a very wide range, so consider some of the issues that could determine if its achieved service life may be at the lower or higher end of this scale.

Other Factors

The type and grade of oil are very important. If the oil is “special purpose” like fire resistant, for example, it could have a negative influence on the achieved service life. The fact the system runs cool (43°C is cool for a hydraulic system) is generally a plus for reliability, both for system components and the oil itself. At this operating temperature, there really is no excuse for temperature-related lubrication issues caused by low viscosity and subsequent loss of oil-film strength.

Also, there is an apparent commitment by the operator to maintaining a high level of oil cleanliness, which extends hydraulic component life. And the fact that suction strainers are not installed is a plus for pump inlet conditions, as is a flooded inlet (head of oil above the pump).

All other things equal, these two factors combined mean that the joint between the piston and its slipper should not be put in tension during intake. Premature failure resulting from piston-slipper detachment, then, is unlikely to occur assuming the pump shaft-speed stays within allowable limits.

We also need consider the pump’s actual operating parameters. In other words, how hard is it working? This encompasses how fast it is spinning, what pressure it is operating at, and its duty cycle — how many minutes of each hour the pump is under load.

According to Bosch Rexroth’s data sheet, the A4VSO250’s maximum shaft speed is 1,500 rpm or 1,800 rpm if the pump’s maximum displacement is reduced or its inlet pressure is boosted. If the pumps are coupled to six-pole electric motors on a 60-Hz ac supply, they’ll spin at 1,200 rpm, which bodes well for long pump life. If they’re spun by four-pole motors at 60 Hz, they’ll be right on the limit at 1,800 rpm, which is not as conducive to long service life.

Similarly, the A4VSO series pumps are rated at 350 bar (5,076 psi) continuous. If the pumps’ pressure compensator is set at 280 bar, this is a big plus for service life extension. Conversely, a setting at or near 350 bar is not as constructive for long life.

Likewise, if the pumps spend 54 min of every hour (90% duty cycle) on load, they’re not as likely to achieve service life at the high end of the scale as they would be if they were on load, say, 42 min of every hour (70% duty cycle).

To summarize, if these particular pumps are running on a mineral oil of the correct viscosity, with a cleanliness level of ISO 15/12 and an unrestricted, flooded inlet, and if they are spinning at 1,200 rpm with their pressure compensators set at 280 bar at a duty cycle of 70%, then it wouldn’t be too unrealistic to look for a 20,000-hr service life or more!

But if they’re running on special-purpose oil with properties inferior to that of mineral oil, spinning at 1,800 rpm, with their pressure compensators set at 350 bar, at a duty cycle of 90%, then a 10,000-hr service-life could be great hunting — all other things equal.

Running To Failure

Of course, this is no more than an informed estimate based on what we know about the pump and its installation. And in a new system like this one, a hidden design flaw in the hydraulic circuit could compromise pump life. For example, the pumps may be subjected to intermittent pressure spikes due to rapid valve shifts and the absence of a spike relief-valve or accumulator. And this may only become obvious over time, such as after a pump failure!

Running a hydraulic pump to failure is never a good idea because there is always the risk of consequential damage to other components, and the pump’s rebuild cost increases significantly. So, the task here is to manage pump change-outs in a way that minimizes this risk while reliable, historical data on achieved service life is collected.

For example, if we are thinking 20,000 hr is the “right” number, we might pull the first pump out at 12,000 hr. When torn down and inspected, if everything looks okay, we might then pull the second pump at 15,000 hr. If it looks all right, we might pull the next at 17,500 hr. And if that looks fine, the next stop could be 20,000 hr. Then, there will come a point where, if the service-life envelope is pushed too far, the risk of an in-service failure dramatically increases. One ought not to get too greedy.

This approach also presupposes the changed-out pumps will be torn down and inspected by people who know what they are looking at and will report their findings with respect to possible service-life extension in an unbiased way.

And although not always conclusive, condition monitoring also could be implemented to aid decision making in the staged, change-out approach discussed above. When it comes to hydraulic pumps, however, effective condition-monitoring techniques are limited. In the case of a piston pump, the case-drain line is probably the best source of information, both in terms of leakage rate and wear metal generation. To be meaningful, any changes in either of these indicators must be trended over time.

Brendan Casey is the founder of HydraulicSupermarket.com and the author of The Hydraulic Troubleshooting Handbook, Insider Secrets to Hydraulics, Preventing Hydraulic Failures, Hydraulics Made Easy, Advanced Hydraulic Control and The Definitive Guide to Hydraulic Troubleshooting. A hydraulics specialist with an MBA, he has more than 20 years experience in the design, maintenance, and repair of mobile and industrial hydraulic equipment. For more information, visit www.HydraulicSupermarket.com