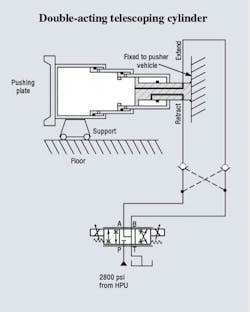

The manufacturer had a nuisance problem with the cylinder drifting out when the directional valve was in the neutral position and the vehicle was moved to a different location or position.

The engineer in charge of the project added a double pilot-operated check assembly to hold the cylinder in place.After the piloted-operated check valves were installed, and the system cycled several times — removing most, if not all of the air — they moved the assembly into position to form a part. Much to their surprise, the smallest moving stage ballooned and blew the rod gland out. The picture shows the deformation near the end of the rod.

Any idea what caused the problem?

Solution:

Whenever applying pilot-to-open check valves (PO checks) to cylinders, the pilot ratio of the check valve needs to be considered. This ratio is the force required to open the check that has an opposing force trying to keep it closed. This is not as simple as it sounds. As the pressure to move the cylinder and open the check increases, the force on the backside of the check increases from the incoming pressure pushing on the cylinder. This, in turn, causes the pressure on the opposite side of the cylinder piston to increase. This increase in pressure increases the force holding the check closed.

The pilot ratio, say a 3:1, means the pilot pressure to open the valve only needs to be slightly more than 1/3 of the pressure holding it shut. A 2100-psi force holding a check valve shut only needs a little more than 700 psi on the pilot line to open the check valve if not used on a cylinder application. There are formulae that can be used to determine the minimum pilot ratio needed when used on cylinder applications. If the pilot ratio is too small, the check will never open, causing the pressure between the check and cylinder to intensify beyond the cylinder’s burst pressure rating.

A check valve with a larger pilot ratio was installed, which solved the problem.

Robert J. Sheaf Jr., is founder and president of CFC Industrial Training, a Div. of CFC Solar, which provides technical training, consulting, and field services to any industry using fluid power technology. Visit www.cfc-solar.com for more information.