Allow me to preface my article with a recent accident: A maintenance technician was nearly killed when the tilt cylinder hose assembly that was made by an untrained technician unexpectedly failed, causing the mast to tilt forward and stop a few feet from a steel structure. The victim was apparently spared from severe injury, and possibly death, for two reasons. First, he was wearing a safety harness. Second, the out-of-control mast did not strike the steel structure.At the time of the accident the forklift was apparently being used in strict accordance with OSHA regulations.

Regulatory groups and manufacturers have developed what they refer to as “safe” methods for lifting personnel with a forklift (OSHA 1926.602) — or if you will, licensing forklift owners and operators to use their forklifts as crossover vehicles. In addition to transporting cargo, they can be used as “mobile elevating work platforms for personnel.”

OSHA’s committees did, however, mandate a few stipulations:

1. The work platform must be equipped with standard guardrails or equivalent means, and must be firmly secured to the lifting carriage or forks.

2. The hydraulic system must be designed such that the lift mechanism will not drop faster than 135 ft (41 m) per minute in the event of a failure in any part of the system.

3. The operator must be in the driving seat while workers are on the platform.

4. The operator must be in the driving seat while raising or lowering the platform.

5. The forklift must not travel from point to point with the work platform elevated at a height greater than 4 ft (1.22 m) while the platform is occupied. When necessary, an occupied platform can be moved as long as the forklift is “inched” at a very low speed.

6. The area between the person on the platform and the mast must be guarded to prevent contact with chains or other pinch points.

The preceding stipulations are well-founded. However, could the regulatory groups and manufacturers have overlooked other critical elements that could cause or contribute to the uncontrolled descent of a forklift’s lift or tilt mechanisms?

OSHA’s 135 ft/min descent rate rule is preposterous because it is impossible to control the descent rate of the lift mechanism “in the event of a failure in any part of the system.” Here are a few examples of failures that could cause uncontrolled descent of a forklift’s lift mechanism:

• lift chain failure,

• cylinder retaining pin failure,

• cylinder internal seal failure,

• cylinder rod failure,

• mast guide wear-plate wear, or

• hose failure.

Most of these failures are caused by inadequate maintenance training, poor or non-existent service and repair, or forklift abuse.

Like apples to oranges

From a design point of view, comparing forklifts to aerial platforms is like comparing apples to oranges! The fundamental purpose of a forklift is to transport cargo with the added convenience of self-loading and unloading with the aid of hydraulics. The fundamental purpose of an aerial work platform is to elevate and transport personnel within the guidelines of safe operation.

Forklifts and aerial platforms both share similar hydraulic components from an operational point of view. However, an aerial platform designer has an additional design responsibility — to make sure the platform cannot fail under any circumstances.

An aerial platform has many hydraulic safety valves that are not usually incorporated into a forklift’s hydraulic system design. This makes a forklift inherently unsafe for use in elevating or transporting people. Forklift manufacturers aren’t shy about warning of the consequences of using their products for this purpose.

Forklifts do not have redundant safety components or systems to specifically protect the rider in the event of the unexpected failure of a critical hydraulic or mechanical component. On the other hand, aerial platform designers focus heavily on platform reliability and machine stability, which makes safety the nucleus of aerial platform design. Accordingly, aerial platforms have redundant safety components and systems for the specific purpose of protecting the rider should unexpected failure of a critical hydraulic component occur.

Using a forklift as an aerial platform puts the rider’s life in the hands of the forklift driver. A conventional aerial platform, on the other hand, places the rider in control of all vehicle functions, including propulsion and steering. (For a case history about this, find the colored sidebox on page three.)

The weakest link

However, the issue of forklift safety extends beyond the boundaries of forklift design. It relies heavily on the qualifications and training of forklift maintenance personnel. The most powerful argument against using a forklift as an aerial platform has to do with the education and training — or lack thereof — of maintenance personnel.

Safe and predictable forklift operation (OSHA 29CFR1910.178O) can only be achieved if a forklift is expertly maintained. It is nearly impossible to meet OSHA’s requirements if the people responsible for maintaining the forklift are untrained — especially on systems as critical as hydraulics. It’s ironic, then, that more than 98% of the people in the U.S. who maintain, service, and repair hydraulic systems and components are not properly trained.

OSHA 29CFR1910.1780 is a law mandating that operators be certified in the safe operation of a forklift. It requires hands-on and formal classroom training. However, the mechanics responsible for the safe and proper operation of a forklift are ignored by all regulatory groups, including the owners and operators of forklifts.

So why aren’t mechanics held to the same standard as operators? Moreover, why do the regulatory groups and manufacturers look the other way with respect to training and certification of mechanics?

Flying is a relative term

To avoid an unimaginable toll on human life due to crashes born of poor repair and maintenance practices brought about by untrained personnel, the federal government — the Federal Aviation Administration (FAA) — passed into law a bill that made it a federal crime for untrained/unauthorized personnel to perform any service or repair work on an airplane. The “flying public” feels safe thanks to “Uncle Sam.”

Unfortunately, the same cannot be said for the aerial platform industry — it’s a veritable “free-for-all.” Literally anyone, regardless of training or experience is permitted to service and repair all types of personnel lifting mechanisms — including forklifts, cranes, basket trucks, etc.

When a person is elevated by means of a forklift, basket-truck or an aerial platform, that person is, for all intents and purposes, “flying.” Ironically, the life and limb of these “pilots” is generally in the hands of people who have little or no training!

Needless to say there must be a reason why the regulatory groups and manufacturers — the people who never in the course of their work have to risk their lives “flying” these unreliable and unsafe machines — cow-towed to corporate America and allowed them to make a forklift a “crossover” vehicle. Could the reason be green in nature — money?

The vast majority of people who maintain, service and repair forklifts, and especially forklift hydraulic systems, have absolutely no formal training. This leaves the majority of forklifts highly susceptible to accidents, which could result in severe injury, death, or substantial property damage.

In my very strong opinion, the regulatory organizations and manufacturers made a very serious oversight when they ignored a critical aspect of safe and reliable forklift operation — the mechanic.

If it ain’t broke, don’t fix it

Equally as critical is the poor state of maintenance, in general, of forklifts. They are generally maintained on the basis of if it ain’t broke don’t fix it. Here’s why:

Inadequate maintenance —Forklift maintenance is generally performed on the basis of crisis management. Machines are typically run into the ground and only then do they get the attention they need — maybe! Repairs are seldom done properly because maintenance personnel are generally not empowered to make decisions. Supervisors usually dictate how repairs should be executed, with the main objectives being cost and time rather than quality and reliability.

Furthermore, less than 1% of the hydraulic components on a forklift are removed for proactive maintenance. Instead, they are maintained on a fail-first basis. Unfortunately, this problem is not unique to the forklift industry. The vast majority of hydraulic systems operating in plants and on mobile machines operate until a failure occurs.

A low priority— When a forklift is sidelined, production is usually unaffected. Most plants usually have a backup forklift or can rent one if needed. Therefore, maintenance and production supervisors and managers make little time to schedule service on non-critical machines such as forklifts.

Equipment abuse — Forklifts are generally abused. Forklift operators routinely spin the tires and shift the drive into reverse (or forward) while the vehicle is traveling in the opposite direction. Most forklifts show multiple scrapes, dents, and other body damage from repeated collisions. The term unreliable is synonymous with neglect. Neglected machinery will inevitably break down unexpectedly.

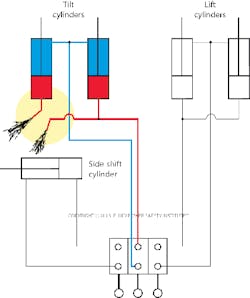

Misconceptions — Don’t be fooled by dual cylinders. A pair of cylinders may seem to provide a redundancy if a hydraulic line fails or a certain type of mechanical failure occurs in one cylinder. However, the “good” cylinder will not keep the platform upright. The lines that supply oil to the cylinders are connected in parallel. This means the failure of any transmission line that routes fluid between the control valve and the cylinders will result in a total loss of that system’s motion control, leaving the rider’s fate up to the laws of gravity!

Conclusion

I cannot agree with OSHA’s and manufacturers’ decision to permit forklifts to be used as substitutes for aerial platforms. Thus, the Fluid power safety Institute issues the following warning:

Using a forklift as a work platform is inherently dangerous and can lead to accidents, which could result in severe injury, death, and substantial property damage.

The regulatory groups and manufacturers appear to have ignored critical safety elements in their haste to kowtow to industry. There are, and always will be, inherent risks associated with using a forklift for any purpose other than what it’s intended to be — a cargo carrying vehicle — unless it undergoes extensive design changes to incorporate all the features needed to make it fail-safe. Moreover, regulatory groups and manufacturers should focus on the state of forklift, crane, and aerial lift maintenance training.

It doesn’t take a rocket scientist to figure out that regardless of how well a vehicle driver is trained, his/her safety — and the safety of those who work around the equipment — lies squarely on the shoulders of the maintenance mechanic.

A forklift is as safe and reliable as the people who service and repair it, regardless of how well the operator is trained.

The Fluid Power Safety Institute invited (via e-mail on October 8, 2007) two major forklift manufacturers to participate in this safety alert, specifically on the issue of descent rates in the event of an unexpected failure. To-date, these manufacturers — Toyota and Hyster — have ignored our attempt to open dialogue on these critical issues.

Rory McLaren is Founder and Director of The Fluid Power Safety Institute, Salt Lake City, which presents safety-based hydraulic workshops. Find a schedule at www.fluidpowersafety.com.

Case history: worker falls when cylinder lowers independent of lift-mechanism

An electrician asked the forklift driver to hoist him to the ceiling to attend to a defective light, which was at an elevation of approximately 20 ft (6 m) from the factory floor. He used a pallet as a work platform.

The driver was sitting in the forklift receiving instructions from the electrician. While the electrician was busy attending to the light, the forklift driver apparently struck up a conversation with a colleague.

A short while later, the electrician shouted to the forklift driver to lower him to the ground. The driver, without looking up, responded by activating the lever to lower the platform. However, he continued with the conversation.

A minute or so went by and the electrician repeated his request for the driver to lower him to the ground.

This prompted the driver to glance forward. To his horror, the lift mechanism’s cylinder rod was completely lowered while the platform remained aloft.

The forklift driver, realizing the gravity of the situation, (the slightest movement could cause the platform to come crashing down) immediately activated the control valve hoping to raise the cylinder rod to meet the platform.Unfortunately, the electrician became impatient and turned around to see why the operator was not responding to his commands. His moving caused the mast sections to realign. The driver watched in horror as the platform came crashing down to the concrete floor below (Figure 2).

As a result of the fall the electrician suffered severe back injury and multiple bruises.

Note: On certain forklift models mast wear guides can wear out and cause the mast section(s) to temporarily seize while the lift-mechanism is at maximum elevation. This situation can leave the “rider” vulnerable to a serious free-fall accident because the lift-mechanism’s lift cylinder(s) can lower independently of the lift-mechanism.

The OSHA descent-rate rule appears to apply to all forklifts regardless of type, age, or condition. Many forklifts do not have hydraulic safety valves (velocity fuses) integrated in the lower port of the mast cylinder(s). Consequently a hose failure, for whatever reason, can cause the lift mechanism to “free-fall,” leaving the rider susceptible to severe injury or death.

The regulatory groups and manufacturers appear to have overlooked problems associated with an unexpected failure of a forklift’s mast tilt mechanism, which also operates with hydraulic cylinders.

A forklift’s tilt angle averages 3º forward and 3º backwards from center. The distance of lateral travel at the top of a fully raised mast is approximately 6 ft (1.83 m). This number varies according to maximum lift-mechanism height and maximum tilt angle.

The unexpected failure of a tilt cylinder hose or mechanical part could result in a very serious accident. For example, a forklift is being used to elevate a person to a height in a building to replace a broken light bulb. While the person is working overhead one of the hydraulic hoses in the tilt cylinder circuit unexpectedly fails causing the mast assembly to lurch forward uncontrollably throwing the lift mechanism against the structure. The person cannot be thrown from the device because, according to OSHA regulation, he/she is securely harnessed. However, his/her body is thrown against the side of an adjacent structure violently, which could cause severe injury or death.