If you have a wood-burning fireplace or stove, this long, cold winter may have depleted your stockpile of firewood. And if you’re like most fluid-power aficionados, you’ve dreamt of applying your knowledge to build your own hydraulic log splitter.

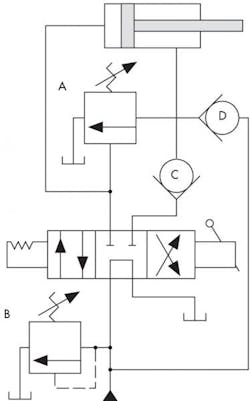

Reader Jean-Louis Bournival, of Vaudreuil, Quebec, proposed the regenerative circuit shown here. It uses unloading valve A set about 120 to 150 psi lower than relief valve B. The circuit provides high extension speed until the cylinder meets resistance and then automatically produces higher force at lower speed until the log splits.

Referring to the schematic, with the directional valve shifted for cylinder extension, pressurized fluid flows into the cap end of the cylinder. Fluid flowing from the rod end is blocked from returning to tank by check valve C. Instead, fluid flows through check valve D and combines with pump flow to extend the piston at high speed. When pressure in the cylinder's cap end reaches the pressure setting of valve A, pump pressure opens it, allowing fluid from the cylinder’s rod end to flow to tank. Check valve D prevents pump pressure from acting on the rod end of the cylinder, so full pressure is applied to the piston from the cap end. Of course, this circuit will perform in other high/low applications.