This file type includes high resolution graphics and schematics when applicable.

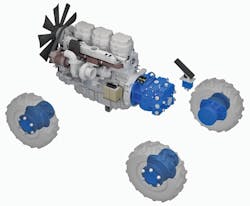

Poclain Hydraulics, Verberie, France, is using LMS Imagine.Lab AMESim software (also called AMESim) from Siemens PLM Software to help design robust hydrostatic systems, such as transmissions for use in heavy duty vehicles. In recent years, automotive suppliers have shifted from providing components to providing complete systems to their original OEM customers. Poclain Hydraulics also has made that transition, implementing new competencies that enable the firm to perform simulation on the full transmission system of its customers’ machines.

Related Articles

• Water Hydraulics Pushes Into High-Pressure Systems

• Linearized model of a hydraulic motor

• Respect seals – they’ve earned it

The use of AMESim enables Poclain to simulate transmission behavior, helping its engineers develop answers to given issues faster and at a lower cost. “AMESim enables us to imagine new solutions because of a better understanding of the system,” says Gilles Lemaire, Poclain Hydraulics’ scientific support manager. “In particular, the simulation enables us to focus on variables that cannot even be measured, and test new concepts without the need of an expensive prototype. For vehicle simulation, even if we have a good knowledge of each component, the interaction between them is not always easy to evaluate.”

Poclain chose AMESim for this work because of the diversity of available libraries and the different levels of simulation provided—from detailed hydraulic components to hydraulic systems and complete vehicles. Another factor was the ability to address global system simulation with an explicit representation of components, such as pumps, motors, and valves.

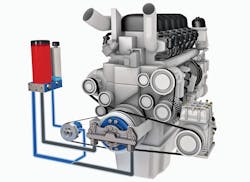

Making a more efficient passenger bus

Take the example of a new vehicle, like a hybrid commercial passenger bus: Poclain Hydraulics initially strives to understand the effectiveness of an existing bus, taking into account the vehicle’s duty cycle, driver, and local traffic laws. The second phase is to study new solutions and analyze their efficiency—not only on the actual duty cycle, but also with respect to the robustness of the solution under different load cases.

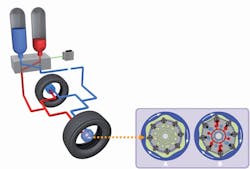

The main issues for the bus project are to how to store the maximum amount of braking energy and how to release it as efficiently as possible. To store the maximum amount of energy, the size of the system must be adequate to the requirements of the driver at any time during the duty cycle, under any condition of use. By grasping the efficiency of each component of the hydraulic system at any phase of use, the simulation enables global efficiency for the energy release. This is not easily measured on an actual vehicle, but readily simulated on computers.

The main contribution of the simulation is to analyze the impact of the system on the fuel consumption of the vehicle, as affected by the main mechanical transmission and the engine. For example, in decreasing the power demand on the engine during restitution phases, the impact on its efficiency was not always positive. “Using the simulation capabilities of AMESim, we were able to estimate the best way to release the stored energy by improving the control of the hydraulic mechanical systems,” says Lemaire. “We also particularly focused on the way the gearbox is controlled during braking to make all of the systems work together. This provides the best experience for the driver, and maximizes energy regeneration.”

From this analysis, Poclain engineers adapt new components with better efficiencies while choosing the right size of components, keeping in mind the results for various duty cycles. “We end up with a good knowledge of the application, a good understanding of its functionality, and important clues for its improvement,” notes Lemaire. “At a higher level, this experience enables us to analyze a new application, such as ‘duty cycle + vehicle,’ to predict potential energy regeneration solutions.”

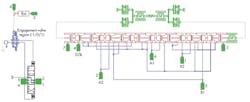

“At the same time, we take advantage of the different level of details offered by AMESim in order to investigate transient phases,” adds Yohann Brunel, advanced studies engineer at Poclain. “We are able to study behavior, such as engagement and disengagement of the motors from a complete representation of each motor piston, in order to synchronize them with the wheel speed.”

This file type includes high resolution graphics and schematics when applicable.

Defining different levels of control

This file type includes high resolution graphics and schematics when applicable.

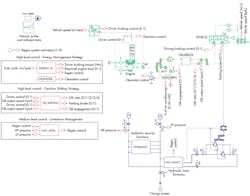

To make everything work together without conflicts or instability, Poclain Hydraulics needed to define different levels of control. The higher level of control helps ensure energy management by splitting power between both systems, while the intermediate level helps ensure each subsystem will provide the required power every time. The lower level manages the functional limitations of the systems. All of the basic controls were made by importing the signal and control library directly from AMESim.

To improve the system by choosing the best components and the best way to control them, the analysis consists of observing the energy that transits into the system during deceleration and acceleration. This enables Poclain engineers to track the lost or non-recovered energy. The main criteria is the fuel consumption on a given duty cycle and the return on investment. Brake wear also can be studied with this analysis.

“The online strategy is validated through AMESim,” says Brunel. “The main difficulty is to find a robust strategy, whatever the duty cycle. The strategy may also have to be adapted when the sizing of the system is modified.”

Utilizing systems approach to achieve high-value solutions

Model-based system engineering is an exceptional way to decrease development costs on existing concepts and to enable more innovative ideas, as is the case at Poclain Hydraulics. It also enables people to work together more effectively, from the component designer to the system designer to the control software programmer.

According to Brunel, the model-based system engineering approach is also an excellent way to work collaboratively with customers. “The degree of collaboration varies,” he explains. “Some customers state their precise specifications and ask Poclain Hydraulics for the right component to handle their needs. The company’s expertise in machine constraints and use of AMESim are critical factors in its ability to deliver complete, high-value solutions, as is its knowledge of sustainable systems.”

Related Articles

• Water Hydraulics Pushes Into High-Pressure Systems

• Linearized model of a hydraulic motor

• Respect seals – they’ve earned it

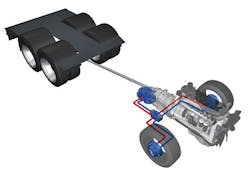

Among offerings for sustainable mobility, Poclain Hydraulics’ truck assistance solution AddiDrive Assist and hybrid system CleanStart are already on the market—both taking advantage of the company’s capability to design dedicated systems for its customers.

“Sustainability is becoming more and more important to the market,” says Yannick Seeleuthner, Poclain’s group marketing manager. “This is not something new for Poclain Hydraulics, because it has always been one of our key values. Hydraulic transmissions have always been among the most energy efficient for mobile applications. Meanwhile, our products are 100% recyclable, and we are implementing solutions in our factories to further minimize our environmental footprint. Reducing fuel consumption for our customers’ machines is a key driver in our design process.”

Bruce Pilgrim is Senior Marketing Writer at Siemens PLM Software, Milford, Ohio.

This file type includes high resolution graphics and schematics when applicable.