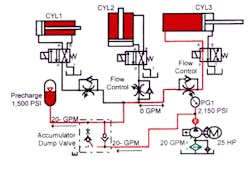

Accumulators used for fast response and over-pressure control of pressure-compensated pumps

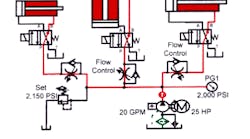

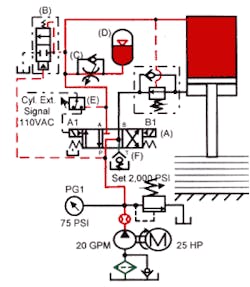

Because most pressure-compensated pump circuits have closed-center or two-position directional valves (such as the one shown in Figure 1-16), they stay at full-pressure, no-flow until a valve shifts. After any directional valve shifts to start an actuator’s movement, pressure in the circuit starts to drop. When the pump sees a pressure drop, its internal mechanism starts shifting as fast as possible to start fluid flowing. Pump shifting times vary, but no matter how fast they shift, the actuator’s initial response will be slowed down.

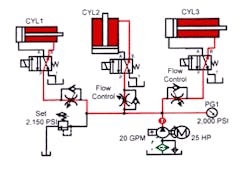

With an accumulator installed, as shown in Figure 1-17, the pump is still at no-flow when the circuit is at rest. However, there is a ready supply of oil at pressure available. As a cylinder starts to cycle, as seen in Figure 1-18, fluid flows directly to the actuator from the accumulator and pressure starts to drop. This pressure drop causes the pump to go on stroke, but now pressure drop is minimal. The cylinder takes off quickly and smoothly, and the pump has time to respond to the flow need.

On the other end of the cycle, if the pump is at full flow and all valves center or all the actuators hit the end of stroke, the flow requirement suddenly drops to zero. The pressure-compensated pump is still flowing at the maximum rate and pressure starts to climb. The pump will continue at full flow until pressure reaches 80-98% of the compensator setting. There has been zero flow needed for some time, but the pump does not know this until pressure is near maximum. When pressure reaches compensator setting, the pump starts to shift to no flow. All pump flow during shifting time has no place to go, so this excess flow generates a pressure spike of five to ten times the compensator setting. This pressure spike can cause premature failure of the pump, plumbing, and actuators.

A common fix for this pressure spike is to add a relief valve near the pump outlet, set 150 to 200 psi higher than the pump compensator (as shown in Figure 1-16). This relief valve should reduce the pressure spike, but it does not lower it as much as it appears. A relief valve remains closed until pressure reaches 90 to 98% of its setting. Once the relief reaches maximum pressure, it starts to open, but by the time it actually relieves, the pressure may be 11/2 to 3 times its set pressure. This reduced spike is better, but still is not as good as what an accumulator could provide.

Other problems can occur with relief valves. For example, if the relief valve setting is at or near the pump-compensator setting, the pump can start oscillating on-off flow. As the pump nears its pressure-compensator setting and starts to compensate, the relief valve starts to relieve. A flow path is created when the relief valve begins to open, so downstream pressure drops, causing the pump to go back on stroke. The drop in pressure allows the relief valve to close, so downstream pressure builds up again. This oscillation cycle repeats rapidly, causing damage to the pump and possible line failure due to shock. In another example, if the relief valve setting is lower than the pump compensator, all pump flow goes to tank at relief pressure, generating excess heat. To avoid these problems, use the correct procedure when setting pressures on a relief valve used to reduce pressure spikes.

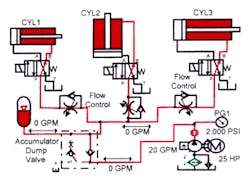

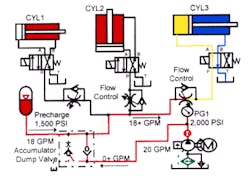

An accumulator absorbs excess pump flow with minimal pressure override or shock. While fluid from the pump compensates from full flow to no flow, as seen in Figure 1-19, it has a direct path to the accumulator. Because the accumulator has a compressible gas in it, it takes in the small amount of excess flow produced while the compensator is reacting. Pressure increase from this additional fluid is imperceptible.

To size an accumulator for fast response of the circuit, plan to have somewhere between 1 and 5 sec of actuator flow before pressure drops below the minimum it takes to move it. A rule of thumb is to have 1 gal of accumulator for every 10 gpm of pump flow.

Using an accumulator as an emergency power supply

A conventional hydraulic system will not operate unless the pump is running. Some machines must be able to cycle to a safe condition after a power or pump failure. Use an accumulator to store enough energy to move the actuators to a safe condition after the pump quits. The operator or setup person can manually cycle the machine into a safe condition by using the stored energy.

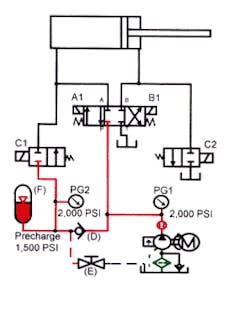

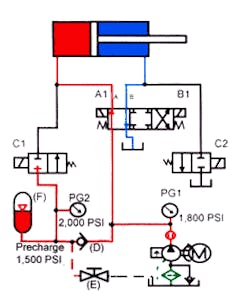

The hopper gate cylinder shown in Figure 1-20 must close in case of a power failure. If the gate stays open, the entire hopper could overflow the truck under it, then dump on the ground. This circuit uses a pressure-compensated pump that maintains pressure with minimal heating during normal operation. An accumulator F stores the first pump flow, check valve D stops accumulator back flow, and normally open directional valves C isolate the accumulator from the cylinder and tank during normal operation.

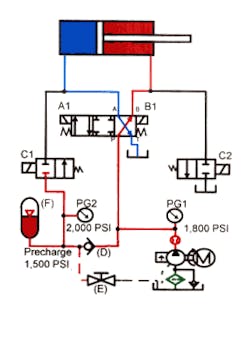

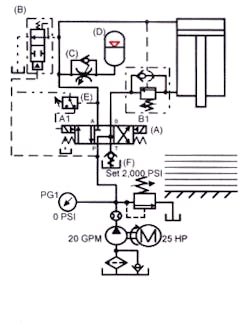

The gate cylinder needs at least 1500 psi, so the pump compensator is set for 2000 psi. This ensures that the accumulator has enough fluid to extend the cylinder when necessary. Because the solenoids on valves C are energized by the pump start command, the accumulator is completely isolated from the cylinder and tank as long as the pump runs. When solenoid B of the 4-way directional valve shifts (as seen in Figure 1-21), the gate opens as fast as the pump moves it.

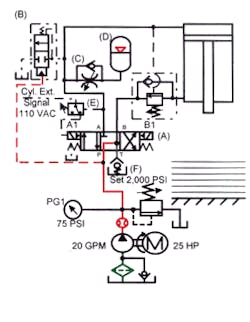

When solenoid A shifts the 4-way directional valve, as seen in Figure 1-22, the gate closes as fast as the pump moves it. When the power is on, the cylinder extends or retracts partially or all the way at the operator’s command.

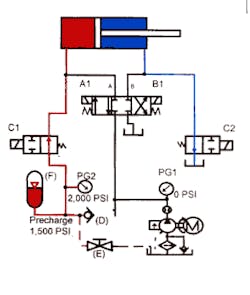

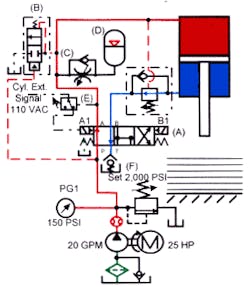

If the gate cylinder is partially or completely open and power fails, the circuit automatically goes to the condition shown in Figure 1-23. In this condition the pump stops, the 4-way directional valve centers, and the normally open 2-way shutoff valves C open.

When power fails, the accumulator has a direct path to the cap end of the cylinder while rod-end oil flows to tank. The cylinder will extend and close the gate using the stored energy in the accumulator. Place warning signs at the gate indicating this equipment can operate at any time without operator intervention.

When using an accumulator for emergency power supply it is difficult to automatically drain it during normal operation. Automatically draining the accumulator would defeat its purpose as an emergency power supply. Add a manual drain valve E, with warning signs to tell maintenance persons to manually drain the accumulator before working on the gate circuit.

Size emergency-power accumulators to hold enough oil to move all actuators to the home position before pressure drops to dangerous levels. Most manufacturers provide formulas in their catalogs and offer several offer excellent computer programs to size accumulators for emergency-power supplies.

Using accumulators for leakage makeup

Some hydraulic circuits, such as in laminating presses, need to hold at pressure for long periods. A pressure-compensated pump could maintain pressure, but energy loss from pump leakage generates heat. Another way to hold pressure for long periods is with a fixed-volume pump and an accumulator. Figure 1-24 shows a press cylinder that must stay extended under pressure for several minutes.

Tee small accumulator D into the cylinder cap-end line through flow control C. Flow control C allows the accumulator to fill quickly but discharge slowly when directional valve A centers or shifts to retract the cylinder. Flow control C should pass enough flow to let the accumulator discharge quickly without system shock when directional valve A shifts to retract the cylinder. Any oil left in the accumulator when the directional valve centers will make the cylinder extend a small amount. Tee dump valve B into the cylinder cap-end line to automatically discharge the accumulator when the pump stops. Tee pressure switch E into the cap-end cylinder line to set pump load and unload pressure. Pressure switch E sets high and low pressures to control maximum and minimum tonnage.

When the pump starts, Figure 1-25, backpressure check valve F gives 75 psi pressure, closing accumulator dump valve B and supplying pilot oil for solenoid pilot-operated directional valve A. When directional valve A shifts, the cylinder starts to extend, Figure 1-26, at whatever pressure it takes to overcome the counterbalance valve. The signal to the extend coil of directional valveA goes through the normally closed contacts on pressure switch E. Because gas pre-charge pressure in the accumulator is approximately 85% of working pressure, no fluid will enter it yet.

When the cylinder contacts the work, Figure 1-27, pressure increases and oil fills the accumulator. Upon reaching the maximum working pressure set by pressure switch E, the normally closed contacts open, de-energizing the solenoid on directional valve A. Directional valve A spring centers, the pump unloads, and oil stored in the accumulator maintains pressure while making up for cylinder and valve leakage.

Bypass at the cylinder seals and/or valve causes pressure to drop slowly to the low-pressure setting of pressure switchE. This low-pressure setting is normally adjustable but must be high enough to keep the parts firmly together. Upon reaching the low-pressure setting, pressure switch E shifts, allowing the normally closed contacts to shift directional valve A to refill the accumulator. Upon reaching maximum working pressure, directional valve A again spring centers to unload the pump, while the accumulator holds its pressing force and makes up for leaks.

A pilot-operated check valve in the cap-end cylinder line between the directional valve and the pressure switch would have less leakage than the blocked port of the spool valve. With a pilot-operated check valve and resilient seals in the cylinder, it is possible to maintain pressure for 2 to 5 min or more. Use an all-ports-open directional valve with the pilot-operated check valve. This accumulator circuit maintains pressure in the cylinder while unloading the pump. It also conserves energy while using an inexpensive fixed-volume pump.

Using accumulators as shock absorbers

Accumulators can reduce damage from shock in some circuits if correctly applied. In other applications, an accumulator may add shock by releasing stored energy too quickly.

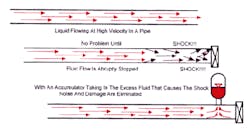

The top half of Figure 1-28 illustrates one way shock is produced. Flow velocity in a hydraulic circuit may be 25 to 30 fps and not cause any problems. However, if oil flow stops abruptly, as seen in Figure 1-28’s middle example, damaging shock can rip out tubing, blow seals, and split pump housings with ease. A column of moving fluid has a lot of energy that can get out of control.

The third example in Figure 1-28 shows a small accumulator teed into the line at the shut off that stops flow suddenly. An accumulator spreads the shock energy over a short period of time and eliminates the potential for damage.

To absorb flow shock, the accumulator is usually pre-charged at about 70 to 80% of system pressure. At this pre-charge pressure, only a small amount of fluid enters the accumulator subsequent to a shock situation. There is also little fluid transfer to take away from or add to the normal pump flow.

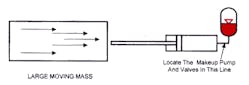

When it is necessary to stop a heavy load, such as shown in Figure 1-29, try using an accumulator and a hydraulic cylinder. The accumulator’s pre-charge pressure holds the cylinder extended, thus making it ready for the advancing mass. When the load contacts the cylinder, it mechanically forces it to retract. As the cylinder retracts, fluid flows into the accumulator and gas pressure increases. As pressure increases, the higher resistance slows the mass more. After the load decelerates, the cylinder might try to push the part away. Add valves between the accumulator and the cylinder to control the shock absorber after it finishes decelerating the load.

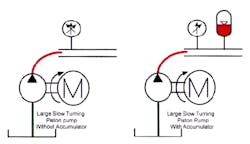

Some large, slow-turning piston pumps send a shock wave into the circuit every time a piston discharges oil. On the left of Figure 1-30, the piston pump does not have an accumulator at the discharge port. Pressure at the gauge will fluctuate from less than system pressure to well above it without an accumulator.

On the right side of Figure 1-30, adding a small accumulator reduces discharge flow and shock damage. A portion of the sudden discharge flow from an advancing piston goes into the accumulator and discharges smoothly while waiting for the next stroke. The pre-charge pressure for this type of accumulator circuit is about 60 to 75% of maximum system pressure.

Accumulator manufacturers have formulas in their brochures to calculate any situation mentioned here. Some suppliers have computer programs that do all the math after asking for circuit parameters.