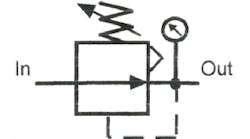

When one branch of a fluid power circuit must operate at a lower pressure, use a reducing valve to provide it. Reducing valves control their outlet or downstream pressure only.

Air line regulators, Figure 16-1, reduce pressure for a pneumatic circuit. Because air in the supply line to a machine is at maximum pressure, energy can be saved by reducing pressure whenever possible. With a compressor setting between 115 and125 psi and a machine requirement of 70 psi, approximately 40% of the input energy would be lost without a properly adjusted regulator. The air-driven machine will work at the higher pressure, but it consumes more compressor horsepower than necessary.

Another use for air line regulators is on retraction strokes of air cylinders. Reducing pressure on a cylinder’s retraction stroke saves air and thus consumes less compressor horsepower.

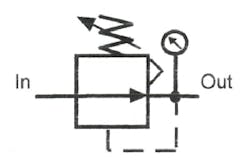

In multiple actuator circuits, it is often impossible to size all actuators to operate at maximum system pressure. For example: when a cylinder needs 5000 lb of force and one standard bore produces only 4712 lb at maximum pressure, the designer must go to the next larger standard bore. However, the next larger bore produces 7363 lb of force, which can cause machine or part damage. Instead, install a pressure-reducing valve in the branch circuit with the over-sized cylinder, as in Figure 16-2, to lower that branch’s pressure to generate the required cylinder force.

A standard reducing valve is normally open. When downstream pressure goes higher than its setting, the valve closes, blocking flow. If pressure downstream tries to increase — say due to resistance from an opposing cylinder — a reducing valve also blocks reverse flow. Escalating pressure in the downstream line continues until something bursts or gets mechanically damaged.

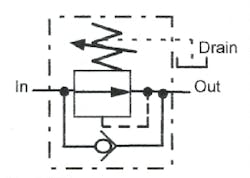

Figure 16-3 shows the symbol for a reducing-relieving valve. A reducing-relieving valve sets maximum outlet pressure, then relieves fluid to tank when outlet pressure tries to go higher. The overpressure could be due to outside forces or possibly high temperature in some environments. A reducing-relieving valve has an integral relief valve with a full-flow line to tank. When pressure in the downstream circuit rises 3 to 5% above reduced pressure, trapped fluid relieves to tank. Adjusting the reduced pressure automatically sets the maximum relief pressure.

Hydraulic reducing valves always have a drain line open to tank for control oil flow. Drain oil flows when reducing valve outlet is lower than its inlet. This generates a small amount of heat in the system. Blocking the drain line forces the valve wide open and lets outlet pressure rise to system pressure.

Multiple pressures in one circuit

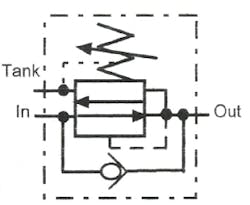

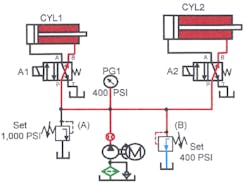

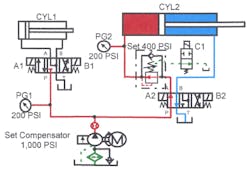

Figure 16-4 has a schematic diagram for two cylinders that need different pressures. One option a novice designer might use is to add a second relief valve. However, second relief valve B reduces pressure in the whole circuit. System pressure cannot go above 400 psi — making high-pressure relief valve A useless.

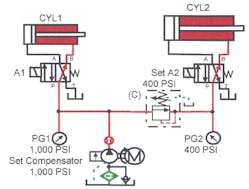

In Figure 16-5, reducing valve C replaces relief valve B. Now each cylinder operates at a different pressure. Note that there is no bypass check valve on reducing valve C. When the system does require reverse flow through the reducing valve, the bypass check valve can be omitted. However, for a circuit with reverse flow always use a bypass check.

With the reducing valve installed in the line that feeds the directional control valve, pressure at both ends of the cylinder is reduced. Also, when the pump is at pressure, reducing valve drain line flow is constant. Drain flow amounts to 20 to 70 in.3 minimum, and produces heat. With several reducing valves in a system, drain line flow might require a larger pump and a heat exchanger.

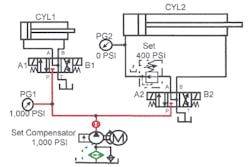

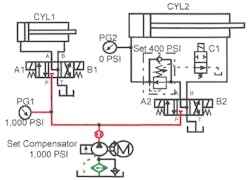

Figures 16-6 and 16-7 show the preferred location for a reducing valve. In Figure 16-6, the circuit is at rest. There is no drain flow with the reducing valve in the line between the directional valve and the actuator. This arrangement eliminates oil heating and provides extra flow to other actuators. When both ends of the cylinder need pressure reduction and/or different pressures, use the arrangement in Figure 16-7. The components cost more up front but the energy it saves often pays for the extra reducing valve.

A reducing valve is normally open from inlet to outlet, but closes when reaching the outlet pressure setting. When an actuator at reduced pressure reverses suddenly, the reducing valve does not have time to open. Oil forced out of the cylinder that tries to go back through the reducing valve keeps pressure on the outlet, holding it shut. A small pilot-drain flow in this blocked reverse flow condition allows very slow reverse cylinder movement. A reducing valve with a bypass check may try to stay closed but will not block flow, so the cylinder reverses easily.

Two-pressure circuit with a pressure-reducing valve

Always connect the drain line of a pressure-reducing valve to a free-flow tank line. Backpressure in the drain line adds to the spring setting, thus raising the set pressure. A constant backpressure can be offset by a lower spring setting, avoiding a problem. With intermittent and/or fluctuating backpressure, the reduced outlet pressure changes when the backpressure changes.

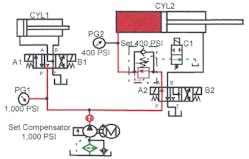

Some circuits require a reduced pressure to position a part, then full pressure to do the work. A reducing valve easily gives two pressures by opening or blocking the drain line. Figures 16-8 through 16-11 show a simple way to get two pressures using a reducing valve and a normally open 2-way directional valve.

Figure 16-8 shows a normally open 2-way directional control valve piped in the drain line. There is no leakage from the drain port in the at-rest condition.

Figure 16-9 shows the directional valve on CYL2 shifted to advance the cylinder to the work at low pressure. During this part of the cycle the reducing valve stays open.

Figure 16-10 shows the cylinder contacting the work with pressure at the reducing valve setting. The low pressure continues as long as required. During this time the operator can check part alignment or other details. If a problem is detected, the operator simply reverses the cylinder to realign any out of place or problem components.

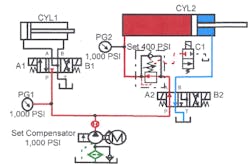

After determining all is well, the operator energizes the solenoid on the 2-way directional valve as shown in Figure 16-11. This blocks drain flow from the reducing valve. Blocking drain flow at the reducing valve causes it to open fully. Backpressure in the blocked drain line, plus the internal valve spring, pushes and holds the spool open. When the reducing valve opens, full system pressure goes to the cylinder to generate high force. This action poses no problem to the reducing valve. This circuit is a reliable way to get two pressures for an actuator.

Remotely operating a pressure-reducing valve

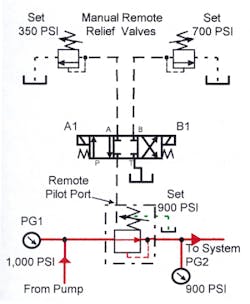

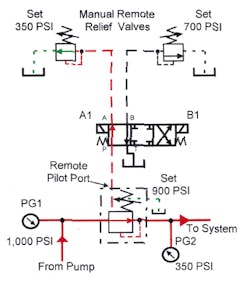

Pilot-operated reducing valves have a remote pressure-control port. Connecting this port to other pressure valves allows pressure to be changed from a remote location. For example, Figure 16-12 shows a reducing valve with a directional valve and two remote relief valves connected to the remote-control port. With the directional control valve in its center position, set the pressure with the knob on the reducing valve. This setting is always the highest reduced pressure for the circuit.

Energizing solenoid A1 of the directional valve, as in Figure 16-13, connects the remote pilot port to the remote relief valve SET 350 psi. Pressure in the system now drops to and holds at 350 psi. Energizing solenoid B1 of the directional valve, as in Figure 16-14, connects the remote pilot port to the remote relief valve SET 700 psi. Pressure in the system now rises to 700 psi and holds at that level.

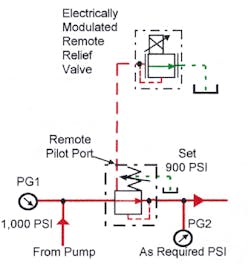

Figure 16-15 shows the reducing valve’s remote port connected to an infinitely variable electrically modulated relief valve. An electronically controlled relief valve changes the reduced pressure infinitely with a remote electrical controller.

Pressure-reducing-relieving valves

When it is possible for an external force to increase pressure in a reduced-pressure circuit, use a reducing-relieving valve. Most modular valves now have the reducing-relieving function. When in doubt, specify reducing-relieving valves where they are required.

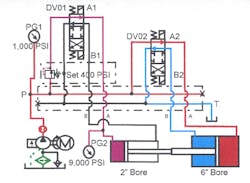

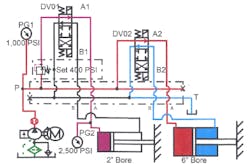

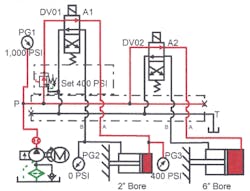

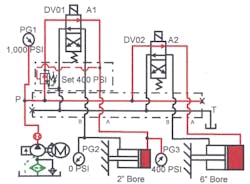

Figure 16-16 shows a large-bore cylinder opposing a smaller-bore cylinder. With a standard reducing valve, oil in the cap end of the 2-in. bore cylinder (CYL1) is blocked after reaching reduced pressure. With a 6-in. bore CYL2 opposing CYL1, pressure could increase to 9000 psi in its cap end. Pressures this high could cause machine damage and be unsafe.

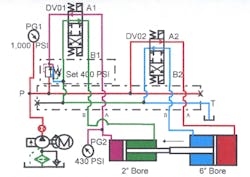

Figure 16-17 shows a reducing-relieving module installed. Now, pressure in the end of cylinder CYL1 only increases to 430 psi. At 430 psi, the relief function takes over and the cylinder retracts.

A cylinder in a high-temperature location may have a similar problem. (Normally, hydraulic systems are not installed in areas with excessive heat, but it is a possibility.) With the cylinder extended at reduced pressure, as in Figure 16-18, heat could cause pressure at a conventional reducing valve outlet to increase and cause failure. Figure 16-19 shows how a reducing-relieving valve allows any heat-expanded oil to relieve to tank.

With slow heat build-up in a location with conventional ambient temperatures, oil expansion that raises pressure is slow enough to pass through the normal drain function.

All pilot-operated reducing valves have a drain line that bypasses control oil. There is always a small amount of oil passing through it. When drain flow is sufficient to handle backpressure from outside forces or heat, a reducing-relieving valve may be unnecessary. If in doubt, specify a reducing-relieving valve for safety’s sake.

Modular pressure-reducing-relieving valves

When buying modular reducing valves or reducing-relieving valves, different options help reduce heat in a circuit while still maintaining good control.

Figures 16-20 and 16-21 show a reducing-relieving valve in the pump port line. The valve has an internal pilot that maintains reduced pressure at the outlet port. This means there is heat-generating flow from the drain line whenever the pump is running.

Remotely piloting the reducing-relieving valve from port A, as in Figure 16-22, reduces pressure only on the extension stroke of the cylinder. While the cylinder retracts and holds, as in Figure 16-23, the reducing valve drain is not bypassing oil. (Some manufacturers put the reducing valves directly in the A or B ports and use bypass checks for reverse free flow.)

In either case, drain flow only takes place during a small portion of the cycle. This may sound unnecessary, but some circuits have multiple reducing valves. Excess drain flow can cause heating and fluid waste. (Pilot flow cannot be used to operate other actuators.)

Extra time spent on circuit design pays off in energy-efficient systems that perform better in the work place.