Servovalve Circuits

When a cylinder or fluid motor application needs precise control of position, speed, or force, an on/off solenoid or proportional solenoid valve will not do the job. Some rolling mills control metal thickness to a tolerance of ±0.0005 in. This is with metal passing through the rolls at 2500 to 3000 ft/min and more. To hold these kinds of tolerances requires more than a go, no-go hydraulic control valve.

Servo directional valves are the only hydraulic valves capable of controlling oil flow and/or pressure rapidly and precisely. Servo directional valves are 4-way, 3-position spool valves with all ports blocked in the center position. Usually, servovalve spools are controlled by high-pressure pilot oil. Many spools have feedback sensing to give repeatable positioning from a given input.

Servovalve spools differ from on/off or proportional valve spools because they have no overlap in center condition. Spool overlap makes proportional valves (and the actuators they control) respond slowly. With no overlap or underlap, any servovalve spool movement gives immediate flow and actuator response. The more closely the spool and body lands match at all four sealing areas, the more responsive the valve. This type of spool is difficult to manufacture, which makes the valve expensive.

Servo systems control actuators to very close tolerances in regard to position, speed, or force. Often a single circuit uses a combination of these functions. A cylinder may have to rapidly approach the work piece, then penetrate it to precise depth at a controlled rate.

While servovalves are very fast and precise, their electronic control is what really makes a servo system work so well. When a signal to move a cylinder starts an action, feedback from its movement modifies valve input to make it match control input. Regardless of pressure drop, fluid viscosity, load, or friction, feedback signals modify valve-spool position to make the cylinder perform exactly as the input signal commands. The only time the actuator falls behind is when it is underpowered.

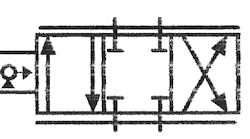

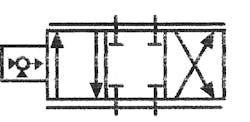

Figures 21.1 and 21.2 show the schematic symbols for a typical servovalve as established by the American National Standards Institute and the International Standards Organization. Both symbols have parallel lines on both sides of the position envelopes. These parallel lines indicate a valve spool with infinite positions. The symbol shows a blocked center (P to A, B to T and P to B, A to T), but the spool seldom shifts all the way to either of these positions. Spools can shift any amount in either direction, producing increasing or decreasing flow to and from the actuator to move it in either direction.

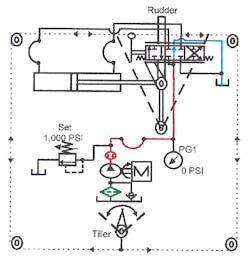

Simple mechanical servocircuit

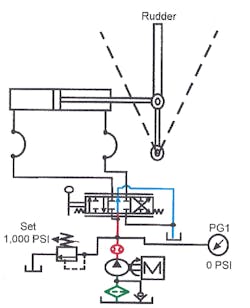

Figure 21.3 shows a simple mechanical servocircuit that controls rudder movement on tugboats. The rudder on a tugboat is big and directly in the prop wash, so the operator must have help in moving and controlling it. The lever-operated hydraulic valve in this circuit directs hydraulic power to move the rudder via a double-acting cylinder. If the valve is in the pilothouse, it does not show rudder position. Without knowing the rudder angle, engaging the propellers might be disastrous in some situations.

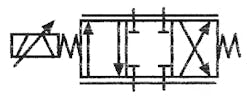

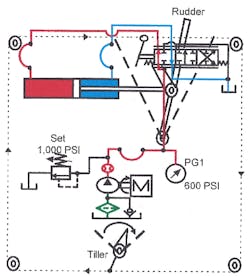

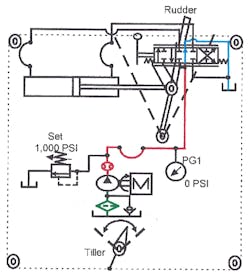

Figures 21.4 through 21.6 show an inexpensive manual rudder-control circuit. This circuit uses the same lever-operated control valve in Figure 21.3, but here it mounts on the rod of the double-acting cylinder. The operator controls the valve from the pilothouse with a lever called a “tiller.” A cable and pulley system connects the tiller to the valve. This all sounds a little crude but it works quite well on small boats.

The clevis-mounted double-acting cylinder attaches to the boat frame and the rudder lever. The lever-operated valve mounts directly to the cylinder rod so it moves with the rudder lever. When the operator moves the tiller to the right, as in Figure 21.5, the lever on the valve moves to the right. When the lever moves, it shifts the directional valve and ports oil from the pump to the cylinder's cap end and returns oil to tank from the rod end. The cylinder moves the rudder to the right as long as the operator keeps moving the tiller.

When the operator stops moving the tiller, as in Figure 21.6, the directional valve, moving with the cylinder rod, catches up and centers. When tiller movement ceases, the rudder stops and holds. The rudder and tiller stay in this position until the operator steers in a different direction. At all times the operator knows rudder position by looking at the tiller angle.

The mechanical servosystem is nothing more than a force multiplier. In this case, the formerly hard-to-move rudder now moves with slight manual force. At the same time, the tiller position indicates the rudder angle because of mechanical linkage feedback.

An automobile power-steering system uses similar circuitry. Steering wheel movement shifts a directional valve that powers a cylinder to move the steering mechanism. When the steering wheel moves, front wheel angle changes. When steering wheel motion ceases the front wheels stop and hold.

The rudder control circuit shown here might be adapted to control a pressing action where cylinder movement follows the motion of the operator's hand. This gives accurate position with a great amount of force from the operator's intuitive feel.

Servovalves for accurate positioning of actuators

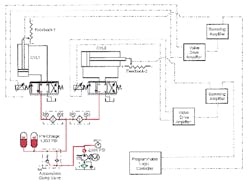

The schematic drawing in Figure 21.7 shows the general arrangement for a typical servocircuit that accurately controls cylinder position. When a cylinder must quickly go to many different locations with an accuracy of less than ±0.020 in., a servocircuit is the best way to control it.

Notice that the hydraulic power unit has a pressure-compensated pump with accumulators. This arrangement holds constant pressure and has ample volume for short bursts of high flow. Without the accumulators, there is a sharp pressure drop when a cylinder starts moving. Fixed-displacement pumps and accumulators work also, but the power unit shown here is best overall.

Place the servovalve as close as possible to the actuator (preferably attaching it directly to it). Use rigid piping when the valve cannot mount directly on the actuator. Flexible lines between the servovalve and the actuator can negatively affect the accuracy and stability of the circuit.

Always install pressure filters in the lines to the servovalves. One pressure filter after the pump might be sufficient when the power unit is close to the valves. Separate filters are advisable when there is some distance to the servovalves. Use a cleanliness level of 1 to 5 µm in a servocircuit. Even normal pump-wear contamination quickly plugs orifices and sticks spools in most servovalves. Do not use a bypass-type pressure filter in a servovalve circuit. Even with a 125-psi bypass spring, contaminated fluid can get around the filter during a normal cycle. It is better to shut the machine down with a clogged filter than with a contaminated servovalve and a dirty filter.

Because the cylinders in this arrangement must stop accurately at many different locations, the circuit includes a feedback transducer at the cylinder rod. When the PLC commands the cylinder to go to a certain location, the PLC sends a signal to the servovalve control card. The servo control card sends an output to the servovalve that starts the cylinder moving. As the cylinder moves, the feedback transducer constantly sends position information to the servo control card. When the cylinder approaches the predetermined position, it slows and stops within a few thousandths of an inch of that location every cycle. Because electronic hardware controls the speed and position of the cylinder, fluid viscosity, load, pressure drop, or machine friction have no effect. The control card modifies the sevovalve shift to offset external or internal system changes as long as the actuator has ample power to overcome them.

In essence the electronics modify servovalve output according to actual actuator movement to get the desired accuracy. A servovalve controls oil flow as a 4-way directional valve would, but it has the ability to change flow continuously. Response time of the servovalve to the electronic controllers' changes is the important thing. Less-expensive, more dirt-tolerant servovalves offer less-accurate control.

With the circuit in Figure 21.7, cylinder positioning at any location within its stroke is attainable with repeatable accuracy to thousandths of an inch.

Servovalves for accurate control of position and velocity

The schematic diagram in Figure 21.8 shows servovalves controlling the velocity and position of a cylinder. The cylinder in this circuit has position and speed control, while the hydraulic motor only has speed control. All previous information about hydraulic power unit type, valve location, and filters applies to this circuit — or any other servo application.

The cylinder in this circuit has accurate positioning as does the cylinder in Figure 21.7, but this cylinder has controlled speed as well. A milling operation requires accurate speed control but also may need depth control. When fast accurate positioning at multiple locations is important, use a servovalve.

When the PLC sends a signal to start the cylinder moving, it smoothly ramps up to any speed desired. A servovalve allows for accurate velocity change anywhere within the stroke when the controller calls for it. At the end of stroke, the cylinder decelerates rapidly and smoothly to an accurate stopping position, without shock. Again, the servovalve performs the 4-way function while the electronic controls change speed and position. The servovalve must respond fast enough to follow the controllers' outputs or the cylinder position and/or speed will not match the machine requirements.

The hydraulic motor in Figure 21.8 must turn at a constant rate regardless of load or changes in pressure drop or fluid thickness. Even with a pressure- and temperature-compensated flow control, motor speed varies as pressure changes. Internal slippage in the motor is greater at higher pressures, so speed decreases even with constant input flow.

With a servovalve feeding the hydraulic motor and a feedback device giving the servocontrol card continuous speed information, motor speed is consistent. The only time motor speed varies is when it stalls at relief valve pressure.

As before, electronics handles all input and modifications to get the desired speed. A servovalve controls oil flow as a 4-way directional valve does, but it also has the ability to change flow as needed. It is the response of the servovalve to the electronic controllers' changes that is most important. Less-expensive, more dirt-tolerant servovalves have less accuracy.

With the circuit in Figure 21.8, cylinder speed is fast, and the cylinder stops in a precise position without shock. The hydraulic motor maintains the set speed regardless of load or input fluctuations — until it stalls from lack of torque. All motions are repeatable.

Servovalves for accurate control of position and force

Figure 21.9 shows a schematic diagram with a servovalve controlling the force of an actuator. The vertical cylinder in this circuit has position control, while the horizontal cylinder has force control. All the information about hydraulic power unit type, valve location, and filters, applies to this circuit or any other servo application.

The vertical cylinder in this circuit has accurate positioning like the cylinder in Figure 21.7, but this cylinder has controlled speed as well. An application might be a milling operation that requires accurate speed control but may need depth control as well. When fast, accurate positioning at multiple locations is important, use a servovalve.

When the PLC sends a signal to stroke the cylinder, it smoothly ramps up to any speed desired. A servovalve allows for accurate velocity change anywhere along the stroke when the controller calls for it. At the end of stroke, the cylinder decelerates smoothly, rapidly, and accurately to the commanded stopping position without shock. Again, the servovalve does the 4-way function while the electronic controls change speed and position. The servovalve must respond quickly enough to follow the controller's output signals or cylinder position and/or speed will not match the machine requirements.

The horizontal cylinder in Figure 21.9 must hold a constant force against a part, regardless of the load or other changes such as pressure drop or fluid viscosity. Even with a constant pressure source, fluctuations in cylinder friction, machine friction, or rod-end backpressure continuously affect cylinder force. To produce consistent cylinder force, use a servovalve to operate the cylinder and load-cell feedback to continuously modify the valve's spool position. Force stays exactly as set, regardless of system changes -- up to relief valve pressure.

As before, the electronics handle all the input and modifications to set and maintain the desired force. A servovalve controls oil flow as a 4-way directional valve, but has the ability to change flow as needed. It is the response of the servovalve to the electronic controller's changes that is most important. Less-expensive, more dirt-tolerant servovalves offer less-accurate control.

With the circuit in Figure 21.9, the vertical cylinder accurately reaches and maintains any position at any speed. The horizontal cylinder holds any force desired up to maximum pressure.

Stepper-motor-driven servovalves for cylinders

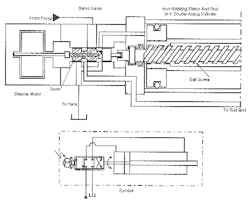

Figure 21.10 shows a simplified cutaway view of a stepper-motor-driven servovalve controlling a hydraulic cylinder. As it receives current pulses, the stepper motor turns in increments of a revolution. Stepper motors may require anywhere from 100 to 500 pulses per revolution. A stepper-motor drive is reliable and repeatable, and produces high torque.

This type servovalve is more dirt-tolerant than other designs. It does not require specific electronics, does not need feedback transducers, and is easy to troubleshoot. This valve may be a stand-alone unit for acceleration and/or deceleration circuits, or for controlling flow -- with or without feedback. Like other servovalves, it has little or no land overlap and a precisely fitted spool to reduce leakage. There are no control orifices to plug, so fluid cleanliness is not as important as with a standard servovalve.

Feedback to a stepper-motor-driven servovalve is mechanical and internal -- similar to the rudder control in Figures 21.4, 21.5, and 21.6. This means that when the cylinder meets resistance it cannot overcome, it will stall. When the cylinder stalls, there is no external feedback to show it has not made its complete stroke. Adding a limit switch or another external signal source helps this problem, but now the circuit resembles a standard on/off solenoid-valve setup.

The response of a stepper motor drive is a little better than the best proportional valves, but not equal to top-of-the-line servovalves.

In the cutaway view, a stepper motor drives a threaded shaft in a threaded spool. The spool can move in and out, but it cannot rotate unless the feedback ball screw in the piston rod turns. Electric pulses to the stepper motor turn the screw in the spool, making the spool shift. Spool shift ports fluid to the cylinder's cap end, making the cylinder extend. When the non-rotating piston and rod start forward, the internal ball screw turns the spool. The ball screw's mechanical linkage turns the spool in the reverse direction of the stepper motor, shifting the spool to stop cylinder movement. When the stepper motor turns, the cylinder extends. The faster the stepper motor receives pulses, the faster the cylinder travels. When the stepper motor stops turning and shifting the spool, the cylinder continues until the ball screw brings the spool back to center. Reversing rotation of the stepper motor reverses all the actions above, including cylinder direction.

From the above explanation, it is obvious that pulsing the stepper motor a certain number of times at a given rate strokes the cylinder to a certain position at a preset speed. If external forces try to move the cylinder out of its position, spool shift — caused by rotation of the ball screw in the piston rod — ports oil to offset these forces.

Stepper-motor-driven servovalves for motors

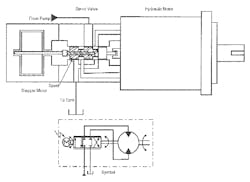

Figure 21.11 is a simplified cutaway view of a stepper-motor-driven servovalve controlling a hydraulic motor. As it receives current pulses, the stepper motor turns in increments of a revolution. Stepper motors may require anywhere from 100 to 500 pulses per revolution. A stepper-motor drive is reliable and repeatable, and produces high torque.

This type servovalve is more dirt tolerant than other designs, does not require specific electronics, does not need feedback transducers, and is easy to troubleshoot. It may be used as a stand-alone valve for acceleration and/or deceleration circuits or to control flow -- with or without feedback. Like other servovalves, it has little or no land overlap. It has a precisely fitted spool to reduce leakage. There are no control orifices to plug, so fluid cleanliness is not as important as with a standard servovalve.

Feedback to a stepper-motor-driven servovalve is mechanical and internal, similar to the rudder control in Figures 21.4, 21.5, and 21.6. This means that when the motor meets resistance it cannot overcome, it will stall. When the motor stalls, there is no external feedback to show it has not made its predetermined position. Adding a limit switch or other external means helps this problem, but now the circuit resembles a standard on/off solenoid-valve setup.

The response of a stepper-motor driven servovalve is a little better than the best proportional valves, but not equal to top-of-the-line servovalves.

In the cutaway view, a stepper motor drives a threaded shaft in a threaded spool. The spool can move in and out, but it cannot rotate unless feedback from the rotating hydraulic motor turns it. Electric pulses to the stepper motor turn the screw in the spool, making the spool shift. Spool shift ports fluid to the hydraulic motor, making it turn. When the hydraulic motor starts to rotate, it turns the spool. The mechanical linkage turns the spool in reverse of the stepper motor, shifting the spool to stop hydraulic motor rotation. When the stepper motor turns, the hydraulic motor rotates. The faster the stepper motor receives pulses, the faster the hydraulic motor turns. When the stepper motor stops turning and shifting the spool, the hydraulic motor continues to rotate until it brings the spool back to its center position. Reversing rotation of the stepper motor reverses all the actions above -- including hydraulic motor's rotation direction.

From the above explanation it is obvious that pulsing the stepper motor a certain number of times at a given rate, turns the hydraulic motor a certain number of revolutions at a preset speed. If external forces try to move the hydraulic motor from its off position, spool shift — caused by feedback rotation — ports oil to offset these forces.