Synchronizing Cylinder Circuits

Some machines with multiple cylinders require that the cylinder strokes be perfectly synchronized for the machine to operate properly. If all the loads, line sizes and lengths, and friction of the cylinders and machine members are identical, they may stroke at the same time and rate. While line sizes and lengths, and machine loading can be controlled to some extent, friction changes constantly. Thus, when cylinders have to stroke together, use some method to synchronize them.

One way of synchronizing cylinders is with external mechanical hardware. Some common mechanisms are racks and pinions, crankshafts, cables and pulleys, and chains and sprockets. The accuracy of these methods depends on the strength of the hardware and the position of the load. Mechanical methods are the most common way to accurately synchronize air cylinders. One advantage of mechanical synchronization is that the cylinders can operate anyplace in the stroke without getting out of phase. The accuracy of mechanical synchronization is about ±0.005 to 0.010 in. -- depending on load variation and strength of the mechanism used.

The most accurate way to synchronize hydraulic cylinders is with servovalves. Servovalves independently control each cylinder with electronic position feedback, and compare each actuator's position with all others. This is the most expensive way to synchronize cylinders but the most accurate. Actuator position within ±0.001 to 0.002 in. of each other is attainable using good servo practices. (This type of synchronizing also works well with cylinders that never go to a home position.)

This chapter deals with ways to synchronize cylinders by using other fluid power components. These circuits show how to arrange the components to hold multiple cylinder positions in close proximity to each other. The simplest circuit uses only flow controls to build resistance to hold the fast cylinder back. The accuracy of flow-control synchronizing is only fair to poor. Some of the more complex ways -- such as using tandem cylinders or a master-slave cylinder arrangement -- hold relative position as low as ±0.010 to 06 in.

To use fluid-power components to synchronize cylinders, all cylinders must come to a positive dead stop at the end of each cycle. Leakage in cylinder seals or valving causes minor position differences after each stroke. When the cylinders all bottom out or meet a positive, level stop, the error of each cycle cannot accumulate. This is the main reason not to use fluid-power synchronizing with cylinders that operate only in mid-stroke.

When testing cylinder synchronization on a machine, always start the circuit with the cylinders detached from the machine. Cycle the cylinders without any load attached. This allows a safe time for air purging and valve adjustment. Any sudden or out-of-control moves will not affect machine members.

Synchronizing with flow controls

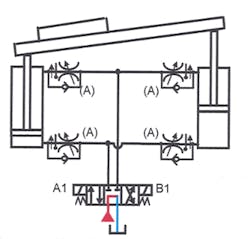

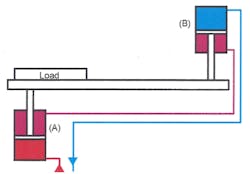

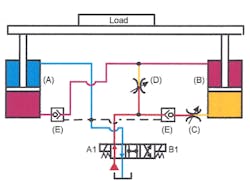

The circuit in Figure 22-1 has no controls except the directional valve. If the pipes are all the same relative size and all the same length; if the load is centered; and if friction of all parts is identical, the cylinders might travel exactly together. Some of these variables are controllable, but things like friction may change even during a single cycle. With the setup in Figure 22.1, the cylinders actually move one at a time until they hit end of stroke or bind up mechanically.

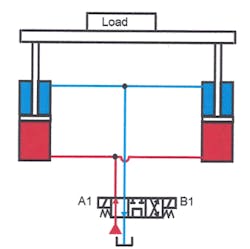

With the off-center load shown in Figure 22-2, the cylinder farthest from the load would extend until it stroked out or locked up -- before the opposite cylinder starts to stroke.

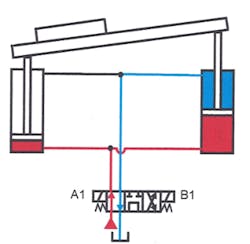

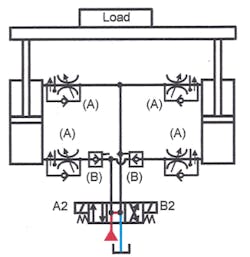

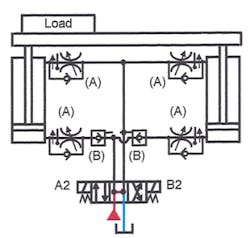

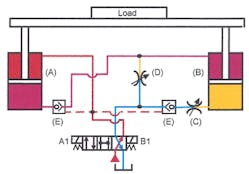

Adding meter-out flow controls to each cylinder port, as in Figure 22-3, adds variable resistance for each cylinder. The added resistance may need to be changed throughout the day because of many factors that affect cylinder movement.

Flow-control synchronizing circuits work with air or hydraulic cylinders. For air cylinders, the problem of compressibility increases potential instability. However, without going to a mechanical or hydraulic option like the tandem-cylinder circuit described in Chapter 3, it is the only way to synchronize air cylinders using fluid power alone.

With flow controls, the cylinders stay reasonably synchronized only if load position does not change. If the load moves, cylinder force must change to maintain synchronization. If load position change is infrequent, resetting flow controls is an option.

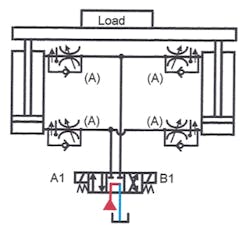

Even with hydraulics, another problem with uneven loads is what happens if the cylinder does not stroke all the way. If the cylinder stops in mid stroke, as in Figure 22-4, oil from the loaded cylinder can transfer to the opposite cylinder and throw the platen out of synchronization. Figure 22-5 shows pilot-operated check valves added to the cap-end lines to overcome oil transfer during mid-stroke stopping. With these check valves in place, oil cannot transfer when the cylinders stop in mid-stroke, so the cylinders maintain their positions.

Another problem with flow-control synchronization is the maximum lifting force. With two identical cylinders positioned parallel to each other, the platen should be able to lift twice each cylinder's force. However, this is only true if the load is centered. With a double load positioned over one cylinder, that cylinder would stall while the opposite cylinder tries to extend. When using flow-control synchronization, size each cylinder to carry the whole load if the load might get off center.

When controlling hydraulic cylinders, it is best to use pressure-compensated flow controls. Pressure-compensated flow controls maintain a constant flow when load differences cause a change in pressure drop.

Double-rod end cylinders in series

Figure 22-7 shows a fairly accurate way of synchronizing cylinders using double-rod end cylinders piped in series. Oil from the directional valve extends the first cylinder, the first cylinder's top port supplies oil to extend the second cylinder, and the second cylinder's top port connects to the other port of the directional valve. In this arrangement, oil trapped between the cylinders must have a means of replenishing or draining. As this circuit operates, cylinder seal leakage either depletes the trapped volume or adds to it. Either situation alters synchronization adversely.

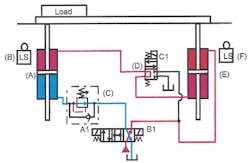

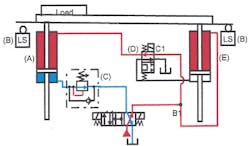

Figure 22-7. Synchronizing circuit with double-rod end cylinders in series flow -- at rest with pump running.

In Figure 22-7, when 2-position, spring-centered, single-solenoid, tandem-center leveling valve D is deenergized, it allows oil to flow from cylinder (A) to cylinder (E). The valve is deenergized while the cylinders extend and retract to do work. (Figure 22-10 shows how the cylinders are leveled at the end of a cycle.)

Energizing solenoid A1 of the main directional valve, as in Figure 22-8, sends oil to cylinder (A) , causing it to extend. Oil from the opposite end of cylinder (A) flows through leveling valve (D) to the push end of cylinder (E). Oil from the opposite end of cylinder (E) flows to tank through the main directional valve. When the trapped volume is completely full and if all seals do not leak, the cylinders synchronize nearly perfectly, regardless of load position.

To retract the cylinders, energize solenoid B1 of the main directional valve as in Figure 22-9. This sends oil to the retract side of cylinder (E). Oil from the opposite end of cylinder (E) flows through leveling valve (D) to the top of cylinder (A). Oil from the opposite end of cylinder (A)flows to tank through the counterbalance valve and main directional valve.

Figure 22-10 shows how the cylinders maintain synchronization as they cycle. When the platen nears bottom, it contacts limit switches B and F. If the switches make simultaneously, no leveling occurs. If one limit switch makes before the other, the cylinders obviously are out of synchronization, so solenoid C1 on the leveling valve energizes. With solenoids B1 and C1 energized, pump oil flows to the retract sides of cylinders (A) and (E), forcing them to retract fully. Cylinders (A) and (E) can retract because the extend sides of both cylinders have a direct path to tank. When both limit switches make, the leveling valve and retract solenoids deenergize. (This leveling circuit also works for horizontally mounted cylinders.)

With series cylinder synchronizing, load placement is not important. The cylinders stay level regardless of load position or weight. The only things a heavy off-center load might cause are more seal leakage, or oil volume changes due to compressibility.

It is important to note that, because the cylinders are in series, they each have to be able to lift the total load. No matter the load placement, or the number of cylinders in series, each one must be capable of lifting the entire load. At the same time only one cylinder's volume is considered when calculating pump flow.

Other ways to use cylinders in series

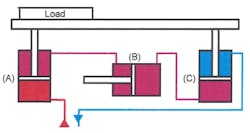

To save cost, reduce potential leakage at the extra rod seals, and eliminate space needed for the second rod, use the circuit in Figure 22-11. The cylinders in this circuit oppose one another, so one extends while the other retracts. This is one way to synchronize single-rod cylinders in a series circuit. Connecting identical rod end volumes together allows series synchronization the same as double-rod end cylinders. Space for the top cylinder could be a problem on some machines so the circuit in Figure 22-12, although more expensive, works equally well. (Use the same tandem-center valve makeup circuit as seen in Chapter 21, figures 7-10 to level the cylinders after each stroke.)

Mounting is more conventional using three single-rod cylinders piped as in Figure 22-12. The only purpose of cylinder (B) is to connect equal areas. This design is still less expensive than two double-rod cylinders and it has one less leak source. This circuit requires make up valves that allow cylinder (C) to retract, cylinder (A) to retract without cavitation, and cylinder (B) to stroke if the other two do not reach home position simultaneously.

Figures 22-13 through 14 show how to attain reasonable synchronization with a set of equalizing flow controls on single-rod end cylinders in series. The cylinders are extending in Figure 22-13. Oil from the directional valve goes through needle valve (C) to the cap end of cylinder (B), thus controlling its speed. At the same time, some bleed oil from the directional valve goes through needle valve (D) to the cap end of cylinder (A). Set needle valve (D) to make up for lower oil volume as it transfers from the rod end of cylinder (B) to the cap end of cylinder (A). Without needle valve (D), cylinder (A) would lag every cycle and be out of synchronization. Changing flow at needle valve (C) means readjusting needle valve (D) also. Both needle valves work best if they are pressure compensated. This is a problem in this circuit because there is bi-directional flow. Refer to Chapter 10, Figure 10-4 to see a pressure-compensated needle valve piped for bi-directional flow.

To retract the cylinders, the directional valve shifts as in Figure 22-14, porting oil to the rod end of cylinder (A). As cylinder (A) retracts, oil from its cap end transfers to the rod end of cylinder (B). Excess oil volume from cylinder (A) goes directly to tank through needle valve (D). Needle valve (C) controls the up and down speeds of the platen.

Each cylinder in a series circuit must be powerful enough to lift the entire load. When load position changes, it affects synchronization due to the resulting change in pressure drop across needle valve (D). An off-center load that is too heavy for one cylinder to lift still allows oil transfer through needle valve (D), throwing the platen out of synchronization. Add pilot-operated check valves (E)if the cylinders must stop in mid stroke. Without these pilot-operated checks, oil transfer through needle valve (D) allows the cylinders to drift.

Double-pump-and-valve synchronizing circuit

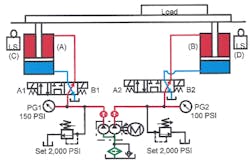

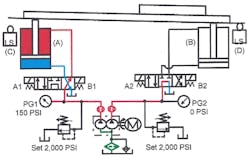

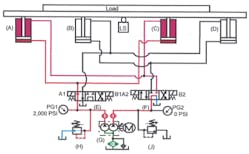

Figures 22-15 through 18 illustrate a common way of synchronizing cylinders. Many designers use this circuit and consider it to be one of the best ways to synchronize cylinders. It is reasonably accurate, but may allow the cylinders to get out of phase in certain conditions.

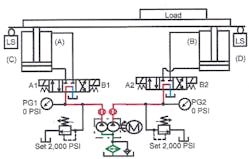

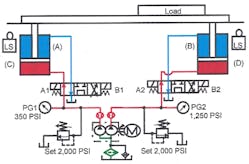

The two pumps in Figure 22-15 have identical flow. They are attached to two double-solenoid, spring-centered valves that are piped to two matching cylinders. Both pumps have a relief valve set at the same maximum pressure. Because both pumps have the same flow and both cylinders use the same volume, the cylinders will stroke at approximately the same rate.

The cylinders are shown extending in Figure 22-16. Energizing solenoids A1 and A2 on the directional valves simultaneously causes the cylinders to extend at the same rate. If one cylinder's load needs more pressure, the pump for that side continues to feed nearly the same flow until the relief valve dumps.

To retract the cylinders, energize solenoids B1 and B2 on both directional valves simultaneously, as in Figure 22-17. The cylinders retract at the same rate.

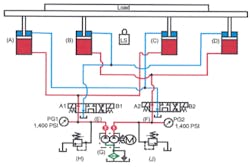

Should the cylinders get out of phase, Figure 22-18 shows how they re-synchronize. Because a separate pump and valve control each cylinder, separate limit switches drop out the retract solenoids after the cylinders reach home. This leveling happens automatically during each cycle, so position errors do not accumulate.

A major problem with this synchronizing circuit is the difficulty of finding two identical pumps. Even pumps manufactured at the same time often have slightly different flows. Any flow variation of the pumps lets the cylinders get out of phase. Another problem is efficiency. As pressure climbs, pump efficiency allows more slip oil, valves leak more, and some cylinder seals bypass more. All of these losses add up to poor performance especially if the cylinders have long strokes.

On top of that, what happens if one solenoid is sluggish or fails to operate? This makes one cylinder start late or not start at all. Starting late causes the cylinders to be out of phase; not starting at all may damage the machine.

This circuit has the same force problem as a flow-control synchronizing circuit. Each cylinder has to be able to lift the entire load. If the load on this circuit gets too heavy for one cylinder, its pump dumps across the relief valve and the cylinder stops. Again the other cylinder continues extending until it damages itself or the machine.

Double-pump-and-valve synchronizing circuit improvement

The circuit changes shown in Figure 22-19 overcome most of the problems mentioned about Figures 22.-5 through 18. Instead of two cylinders as before, use two or more pairs of cylinders. Connect half of the cylinders to each pump/valve combination. Pipe port A of directional valve (E) to the caps of cylinders (A) and (C). Hook port B of directional valve (E) to the rod ports of cylinders (B) and (D). Pipe port A of directional valve (F) to the cap end of cylinders (B) and (D) with its B port hooked to the rod ports of cylinders (A) and (C). Piping the circuit this way uses one pump and valve to extend two cylinders, while this same valve retracts the cylinders extended by the other pump and valve.

Should a solenoid fail, as in Figure 22-19, the platen will not move because, while cylinders (A) and (C) may be trying to extend, oil from their rod end ports cannot get back to tank through valve (F). Also, blocked inlet flow to cylinders (B) and (D) at valve (F) prevents them from stroking -- although leakage past the spool in valve (F) may allow minor movement.

After both directional valves shift and the cylinders are stroking as in Figure 22-20, the pairs of cylinders try to stay level. If pump (G) produces higher flow, cylinders (A) and (C) try to run ahead. Because cylinder (B) is between them, it will either hold the other cylinders back or be dragged along by them. The platen must be strong enough to transmit this differential cylinder loading without flexing.

This circuit is less load-sensitive because the load is always over a pair of cylinders operated by different pumps. Both pumps will relieve to tank before the load stops moving. However, the lightly loaded cylinders can move ahead in relation to the stiffness of the platen and the distance between cylinders.

Use only one limit switch for this cylinder arrangement. To re-phase the cylinders, shift both directional valves to send the cylinders to home position. One relief valve bypasses fluid until the lagging cylinders reach the positive stop.

Spool-type flow-divider synchronizing circuit

Spool-type flow dividers split flow from a single conductor into two separate flows. The split flows may be at different rates if needed, but for cylinder synchronization, they usually are equal. Spool-type flow dividers basically consist of two pressure- compensated flow controls in one body. In this arrangement, each flow control's pressure drop modifies the opposite flow output. Because these flow controls constantly look at each other's pressure drop, they split flow relatively well. (Most manufacturers claim about ±5%, depending on the pressure differential at the outlets.)

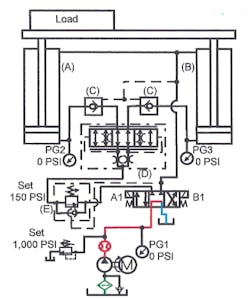

One problem with spool-type flow dividers is that they do not allow reverse flow. Even if they did, there would be no guarantee of equal flow. A spool-type flow divider/combiner allows forward and reverse flow, and equally splits or combines the two flows. Normally a flow divider/combiner is the component of choice in cylinder synchronizing circuits. Figure 22-21 shows a spool-type flow divider/combiner synchronizing circuit. It is similar to a double-pump circuit, but only uses one pump and valve. Flow is split downstream from the single directional valve.

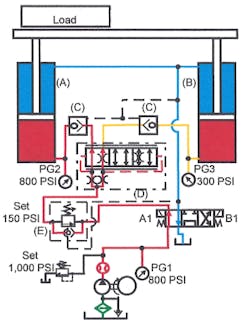

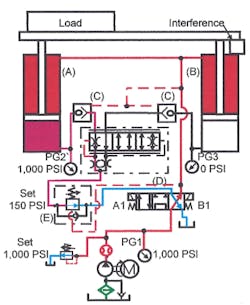

In Figure 22-22, the cylinders are extending. Shifting solenoid A1 on the directional valve sends oil to the flow divider, which sends half pump flow to each cylinder. Even when there is a pressure difference at the cylinders, flows are close to equal. The cylinders extend at about the same rate even with an off-center load. Each cylinder must develop enough force to lift the load above it. If one cylinder reaches its force limit and stops, the opposite cylinder tries but does not completely stop -- due to internal leakage past the flow divider spool. (Figure 22-24 shows the condition of the flow divider when cylinder (B) stalls as it retracts.)

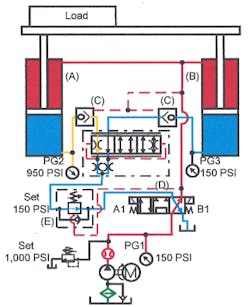

Figure 22-23 shows the circuit after energizing solenoid B1 on the 4-way directional valve. Oil flows to the cylinder rod ends while fluid from the cylinder cap ends combines equally at the flow divider and flows on to tank. The flow divider holds back the cylinder that wants to get ahead -- thus maintaining synchronization. When the cylinders reach bottom, they re-phase automatically if the directional valve is left in the down mode long enough. Internal leakage in the flow divider spool allows the lagging cylinder to continue stroking. (Some flow-divider brands have integral bypasses that operate when the pressure differential reaches a pre-set limit.)

Because the flow divider has a common path internally, fluid can flow between the cap end ports. If the cylinders need to stop in mid-stroke, always use pilot-operated check valves (C) to prevent oil transfer. Control an overrunning load with counterbalance valve (E) between the flow divider and directional valve.

Spool-type flow dividers waste energy. Notice the gauge reading at each cylinder as it extends, PG2 shows 800 psi while PG3 reads 300 psi. In this situation, gauge PG1 at the pump reads 800 psi. The 500-psi drop across the right side of the flow divider generates heat when the cylinders extend.

Spool type flow dividers only split flow into two outputs. It would take three spool-type flow dividers to split flow four ways.

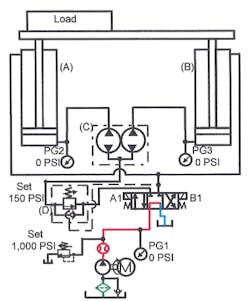

Motor-type flow divider synchronizing circuit

Motor-type flow dividers do not waste energy and are more versatile. One motor-type flow divider can splits flow from a pump and run two or more cylinders in unison. Plus, they offer multiple outlets -- up to ten or more -- and can pass unequal flows when required.

A motor-type flow divider consists of two or more hydraulic motors in one housing. The motors have a common shaft. Thus, when one motor turns, all motors turn. The motors share a common inlet but have separate outlets. Fluid from the pump enters all motors at once, rotating then in unison. If the motors are the same size, output from each section is an equal portion of inlet oil. Because a mechanical motor -- instead of an orifice -- splits flow, there is no energy loss due to different outlet pressures. Figure 22-25 shows a motor-type flow divider synchronizing two cylinders. The flow divider is installed between the directional valve and the cylinders in this circuit.

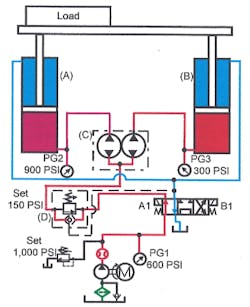

In Figure 22-26, solenoid A1 is energized to shift the 4-way directional valve. This sends oil to the flow divider, which sends equal volumes to each cylinder. The accuracy of motor-type flow dividers depends on the amount of pressure difference at the outlets. The motors have internal slippage that increases as pressure drop increases. The greater the pressure difference, the greater the flow difference and loss of synchronization.

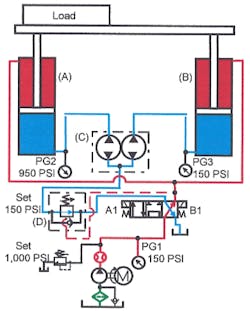

In Figure 22-27, the cylinders are retracting. Energizing solenoid B1 on the directional valve sends oil from the pump to the cylinders' rod ends. As the cylinders retract, oil flows from the cylinders' cap ends through the flow divider to tank. The flow divider combines the cylinder flows and maintains synchronization when the cylinders travel freely.

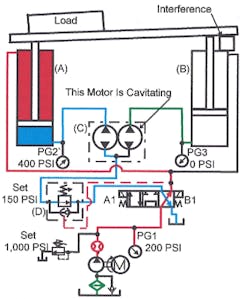

If one cylinder binds up and stops traveling, as in Figure 22-28, all oil from the pump goes to the free-moving cylinder. The flow divider section that is not getting oil from the stopped cylinder continues to turn and cavitate, causing the free cylinder to retract at twice speed. When there is a chance of cylinder binding, install a motor-type flow divider at both ends of the cylinders. A flow divider on the rod end forces the binding cylinder to synchronize or stalls them both.

The internal slip of motor-type flow dividers is usually sufficient to level the cylinders. Another option is integral relief valves that allow fluid to bypass a motor at a predetermined adjustable pressure.

As mentioned, an advantage of motor-type flow dividers is that they waste little energy. Notice the gauge values in Figure 22-26. The left cylinder requires 900 psi, while the right cylinder only needs 300 psi. With those conditions, the inlet pressure to a spool-type flow divider has to be 900 psi. With a motor-type flow divider, the inlet pressure only has to be 600 psi. Because the motor-type flow divider has a mechanical link through a common shaft, energy transfer between sections lowers the required pressure at the inlet.

Another advantage is that motor-type flow dividers with two, three, even ten or more outlets are common. Instead of stacking 2-outlet spool-type dividers, use only one multiple-outlet motor-type flow divider for many circuits.

One caution: motor-type flow dividers will intensify outlet pressure as they operate. (See Chapter 11 for an explanation of motor-type flow divider intensification.) With a 2-outlet equal-flow divider, if relief valve pressure is over half the maximum rated pressure of any component it feeds, install a relief valve at each outlet. The outlet relief valves protect the cylinders, valves, and lines from excess pressure.

Master-and-slave cylinder synchronizing circuit

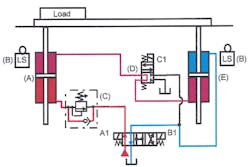

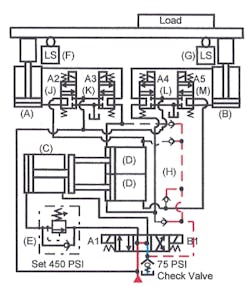

Figures 22-29 through 32 show one of the most accurate ways to hydraulically synchronize cylinders. Figure 22-29 shows the circuit at rest. Cylinder (C) -- mechanically linked to two cylinders (D) -- provides the driving force. The (D) cylinders have the same bore, stroke, and rod diameter as working cylinders (A) and (B). One cylinder (D) connects to cylinder (A), while the other cylinder (D) connects to cylinder (B). In case of external leakage, makeup check valves (H) let oil into the dead areas of cylinders (A), (B), and(D) at low pressure. A 75-psi backpressure check valve in the tank line gives sufficient pressure to make sure the trapped oil volume stays full. Leveling valves (J) through (M) retract the cylinders to home position when they get out of phase. Limit switches (F) and (G) indicate cylinder home positions and operate the leveling valves when the cylinders get out of synchronization. Counterbalance valve (E) stops the cylinders from running away while they retract.

Force from cylinder (C) is enough to do the whole operation by itself. This cylinder produces all the force and passes it on to slave cylinder (D), then to the working cylinders (A) and (B).

The location of the load on the platen affects synchronization only slightly. Energy transfer from the master/slave linkage moves the same volume of oil regardless of pressure. Cylinder (A)operates at twice pressure with the load above it as with a centered load. To protect the cylinders from overpressure, set the relief valve for no more than half the cylinder pressure rating.

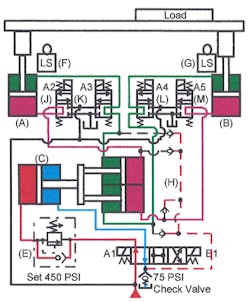

Figure 22-30 shows solenoid A1on the 4-way directional valve shifted to extend cylinder (C). Cylinder (C) pushes cylinders (D), and oil from the cap ends of cylinders (D)flows equally to the cap ends of cylinders (A)and (B). Oil from the rod ends of cylinders (A)and (B)returns to the rod sides of cylinders (D). Cylinders (A)and (B) extend in unison if cylinder (C) has enough power to do the job. If one working cylinder stalls, both stop.

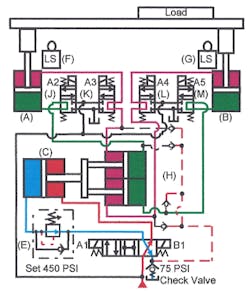

To retract the working cylinders, energize solenoid B1 on the 4-way directional valve as in Figure 22-31. Cylinder (C) then retracts and pulls both slave cylinders (D) back, forcing working cylinders (A) and(B) to retract also.

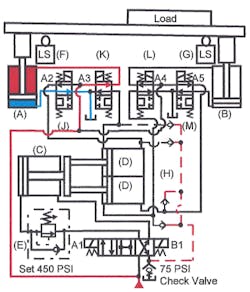

If the working cylinders get out of synchronization, the circuit diagram in Figure 22-32 shows how they level. While solenoid B1 on the 4-way directional valve stays shifted, energize solenoids A2 through A5 on directional valves (J) through (M). This directs pump oil to the rod sides of cylinders (A), (B) and(C), and to the cap sides of both (D) cylinders. At the same time, oil from the cap sides of cylinders (A), (B) and(C) and the rod sides of both cylinders (D) flows to tank. In this condition, the pump forces all cylinders to their home positions, ready for the next cycle.

This circuit is an accurate but expensive way to synchronize cylinders. One advantage is that the master and slave cylinder can be located remotely, to leave the work area less cluttered. Also, energy transfer minimizes the required cylinder size and still handles off-center loads.

Tandem-cylinder synchronizing circuit

Figure 22.-3 shows another very accurate way to synchronize cylinders. The tandem cylinders in this circuit must meet in center even when they run into unequal forces.

Tandem cylinders consist of two cylinders in one housing. They have four ports and the back cylinder is single-rod end while the front cylinder is double-rod end. Because the front cylinder is double-rod end, it has equal areas and volumes on both sides of the piston.

Notice the 4-way directional valve supplies the single-rod cylinders in a conventional manner. The double-rod cylinders have the front port of the left cylinder connected to the back port of the right cylinder and the front port of the right cylinder connected to the back port of the left cylinder.

The tandem cylinders move in unison and transfer energy because hydraulic flow ties them together. If either cylinder stalls, both cylinders stop. Before the cylinders stop, energy transfers through the tandem cylinders and tries to force the lagging cylinder to do its work. The lagging cylinder may see as much as double force before stalling.

The two check valves (C), fed from a 75-psi backpressure check valve in the tank line, allow makeup oil into the trapped volume of the tandem cylinders. The pump makes up for leakage in the trapped volume through check valves (C). Makeup pressure is equal on both sides of both cylinders so the 75 psi has no effect on them. Always furnish bleed ports at both ends of the tandem cylinders to purge any trapped air.

The 2-way, normally closed directional valve (D) between the tandem cylinder connecting lines opens to level the cylinders at one end of the stroke. Leakage at the cylinder piston seals may allow the cylinders to get out of phase. Valve (D) opens when limit switches (E) and(F) do not make simultaneously as the cylinders retract. When one limit makes first, valve (D) opens and allows fluid transfer from one end of the double-rod end cylinder to the other, until both limits make.

In Figure 22-34, solenoid A1 of the 4-way directional valve is energized and the cylinders extend. As they extend, oil transfer in the tandem cylinders maintains near perfect synchronization. If either cylinder tries to lag, power transfers hydraulically through the tandem cylinder lines to keep them in unison. When the load is too great for both cylinders, they stall.

Figure 22-35 shows the cylinders retracting. Energizing solenoid B1 of the 4-way directional valve sends fluid to the rod ends of the single-rod cylinders. As the cylinders retract, the double-rod end cylinders cross piping keeps the machine in synchronization, the same as when they extend.

When the cylinders get close to home, they level or re-phase when necessary, as pictured in Figure 22-36. Limit switches (E) and (F) both have to make to center the 4-way directional valve. If one limit switch makes early, solenoid C1 of 2-way directional valve (D)energizes, allowing the lagging cylinder to transfer oil until it makes its limit switch.

This synchronizing circuit works equally well with air as the power source to the single-rod end cylinders. Use oil in the tandem cylinders because it does not compress. Oversize the oil flow lines for a velocity of 2 to 4 fps to maintain a reasonable speed. Install a makeup oil tank with check valves to feed the tandem cylinders when necessary.