Every compressed air system begins with a compressor — the source of air flow for all the downstream equipment and processes. The main parameters of any air compressor are capacity, pressure, horsepower, and duty cycle. It is important to remember that capacity does the work; pressure affects the rate at which work is done. Adjusting an air compressor's discharge pressure does not change the compressor's capacity — even though many people seem to believe it will.

Several basic air compressor designs — and variations of them — are on the market today. They all fall into two general categories: positive displacement and dynamic. Although the operating specifications for two different types of air compressors may be very similar on the surface, other installation and performance factors can make one design superior to the other in a real-world application. Let's review some of the basic designs and terminology.

|

Power and efficiency Motor or engine horsepower is the nominal rating of the prime mover. Service factor is the additional power built into an electric motor above its nominal rating — expressed as percent. Within the service factor, the brake horsepower driving an air compressor can be higher than the motor’s nominal horsepower. The power efficiency of a compressor is the ratio of the air delivered by the compressor and its input electrical requirements. Efficiency usually is expressed as brake horsepower per 100 cfm of delivered air. |

Reciprocating compressors

Reciprocating compressors are positive-displacement units that trap a charge of air and then physically reduce the space that confines it, causing its pressure to increase. Reciprocating units, often called piston compressors, use a piston, cylinder, and valve arrangement. Their operation is very similar to the familiar internal-combustion engine, but they simply trap and compress the air without adding fuel to explode it. Note that whenever air is compressed, heat is generated. Proper cooling of the internal parts of any air compressor is a critical part of its design.

There are three basic selection decisions that must be made about reciprocating compressors:

• single- or double-acting operation,

• single- or multi-stage configuration, and

• air or water cooling.

In a single-acting piston compressor, the piston only compresses air in one direction of its stroke. In a double-acting model, the piston compresses air with both directions of its stroke. Obviously, because both strokes perform work, a double-acting compressor is more efficient (in moving a volume of air per input hp) than a comparable-size single-acting unit.

A single-stage unit compresses air from inlet to discharge pressure in one operation. A multi-stage unit compresses from inlet to discharge pressure in two or more operations — generally passing the air through an intercooler to remove some of the heat of compression between each stage. This saves power and keeps the compressor's internal operating temperatures lower.

In air-cooled compressors, ambient air circulates around the compressor cylinders and finned heads to provide cooling. Heat transfers through the metal to the air. Air-cooled units are generally designed for 50 to 75% duty cycles, depending on the particular units and their application. In water-cooled compressors, integral water jackets surround the cylinders and heads. Heat transfers through the metal to the water — more effectively than through metal to air. Thus, water-cooled reciprocating units reduce internal temperatures more efficiently than comparable air-cooled units.

Most air-compressor manufacturers promote the two-stage compressor as the optimum machine for producing 100-psi class air — the base pressure level in most industrial plants — providing the best efficiency per dollar cost with adequate reliability of internal working parts. For a reciprocating compressor to be categorized as continuous duty, it is generally agreed that it must be double acting and water cooled. Double-acting, water-cooled reciprocating compressors are offered in a variety of styles that combine efficient air compression with durability and reliability. However, they also are heavy and bulky, making them relatively expensive to install. They generally have more-significant unbalanced forces, which combines with their size to require a special foundation and support.

When they meet selection criteria such as capacity, weight, size, and price, single- and two-stage single-acting reciprocating units are a good choice — particularly in the 50- to 150-psig pressure ranges. (Three-stage reciprocating units are offered, but generally are used for pressures above 250 psig.)

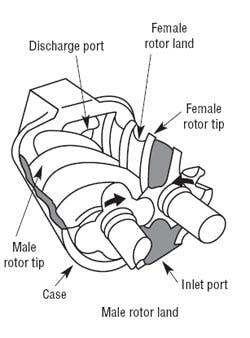

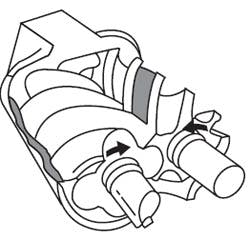

Oil-cooled rotary-screw types

The rotary-screw compressor is another positive-displacement machine. In an analogy with the reciprocating compressor, the male rotor is like a piston, pushing air along the female rotor, which is like the cylinder. Sealing strips are analogous to piston rings, and air is compressed against the stationary end plate, which is like the bottom of the cylinder. This design has been around for more than 50 years. However, until the mid 1970s, it was considered suitable only for engine-driven portable compressorss and small-horsepower electric-motor units because of low efficiency (the ratio of compressed-air delivery to power cost).

In the 1970s, development began on two-stage rotary screw compressors for pressures up to 250 psi. Rotor-profile development during the 1970s, 1980s, and early 1990s has led the oil-cooled rotary-screw design to become the significant choice in electric-motor-driven, lubricated, industrial air compressors, particularly in sizes from 20 to 300 hp.

Then, a significant breakthrough in air-end design occurred. The introduction of the unsymmetrical profile resulted in an efficiency improvement of approximately 15%. This improvement was significant enough to make the oil-cooled rotary-screw compressor competitive in the larger-horsepower sizes for continuous duty. It has almost the same efficiency as the single-stage double-acting units and smaller centrifugal compressors.

Two-stage rotary-screw compressors can approach and sometimes equal the full-load performance of two-stage reciprocating units in 100-psig class service. Today, two-stage oil-cooled rotary-screw compressors are frequently used in the 150- to 400-psia pressure range. They also are used for 100-psi service with significant power savings. Two stages offer advantages associated with lower compression ratio per stage. Reduced pressure differential across the rotors minimizes blow-by and significantly reduces thrust-bearing loads. (Obviously two-stage units require two air ends, which increase the initial cost.)

|

Water-cooled rotary screw types |

The unique characteristic of this compressor is that it is cooled by oil. Oil injected into the air stream absorbs the heat of compression while it is being generated. The heated oil then is taken to an air- or water-cooled heat exchanger for cooling. Because the cooling takes place right inside the compressor, the working parts are never subjected to extreme operating temperatures. The cooling oil never is cracked nor burnt. No matter what the load on the compressor is, there are no hot spots inside the air end. The resulting absence of wear produces trouble-free service and high efficiency. In other words, oil-cooled rotary-screw compressors can run at full load and full pressure —twenty-four hours a day, seven days a week. This compressor's useful life in operating hours and its maintenance cost per hour will be the same as under any other load condition.

Non-lubricated rotary screw types

In addition to the non-lubricated reciprocating compressors that have become so common over the years, there are several versions of non-lubricated positive-displacement lobe or screw rotary compressors. These units are referred to as clearance-type compressors because the internal parts do not contact each other, so they require no lubrication in the compression chamber. Cooling is accomplished through the cylinder walls via water jackets.

|

Lubricated or lube-free? Lube-free compressors use no oil in the airend, and thus add no oil to the compressed air they produce. |

The lobes, or screws, do not drive one another either; they are driven by some type of gear arrangement instead. This drive system also acts as a timing gear to maintain the rotor or lobe profile relationship accurately. Lubricant for the drive train must be confined to the bearing and gear area — and not allowed to get into the compression chamber.

In this basic design, there is a constant leakage rate for any fixed set of conditions. The critical internal clearances are between end covers and the rotor, between the rotor lobes, and between the rotor OD and the cylinder ID. These gaps, combined with no injected oil to help with sealing, are the main reasons why two stages are required for these units to produce acceptable efficiencies in 100-psi class applications.

Because these are rotary units, they enjoy all the advantages of rotaries over similar-sized non-lubricated reciprocating units:

• compact size,

• smooth delivery of cool air,

• ease of installation, and

• simple (but critical) maintenance

They also have some disadvantages, depending on the specific type of compressor and its duty cycle:

• more sensitive to dirty inlet air,

• lower efficiency — resulting in higher power cost, and

• any repair work is more sophisticated and requires specialized training, which the user may not have nor want to have. This means repair work will probably have to be performed by the distributor or the manufacturer.

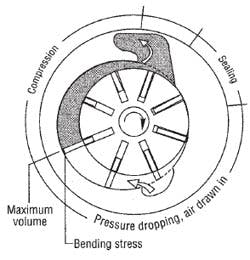

Sliding-vane rotary types

Oil-cooled sliding-vane compressors operate as other positive-displacement compressors do by trapping a charge of intake air — in this case, between the vanes. As the eccentric rotor turns, the vanes are forced into the rotor slots, shrinking the size of the cell holding the trapped air. The air is compressed to full discharge pressure when it reaches the outlet port. The heat of compression is removed by cooling oil sprayed right into the air while it is being compressed. The same oil helps with sealing the vane tips.

For decades, oil-cooled, sliding-vane rotary compressors have been popular for continuous-duty applications. Their design has a number of unique characteristics:

• light weight — yet continuous rating,

• integrated and compact configuration,

• efficient production of compressed air at relatively low rotary speeds,

• smooth operation with little vibration,

• extremely quiet operation,

• coolest possible discharge air, and

• few wearing parts, making the machine easy and economical to repair.

However, the oil-cooled rotary-vane design in its single-stage configuration is limited in capacity. Bending stress applied to the vanes is the problem. The speed, size, and weight of the vanes must be limited for the machine to be durable. Because of this, oil-cooled rotary-vane compressors generally are applied only in a size range between 2 and 100 hp.

Dynamic air compressors

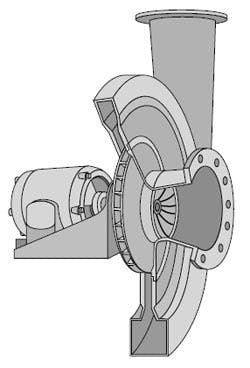

Dynamic, or centrifugal compressors are dissimilar to the positive-displacement machines already discussed because they raise the pressure of air by converting the energy of its velocity into pressure. First, rapidly rotating impellers (similar to fans) accelerate the air. Then, the fast flowing air passes through a diffuser section that converts its velocity head into pressure by directing it into a volute.

Because the centrifugal is a mass flow compressor, it has a limited stable operating range. This has a large effect on economic operation or bhp/100 cfm delivered at part load. Minimum turn-down capacities for centrifugals may vary from 20 to 30% of full load, depending on impeller design, number of stages, etc.

There are limits to the pressure rise that can be achieved in a single stage by a centrifugal compressor — due to both physical and economical restraints — so two- to four-stage units are built that incorporate one to three water-cooled intercoolers. Cooling the air between stages reduces the power required to compress the air further, resulting in more efficient operation. Intercooling actually may permit the desired compression to be accomplished in fewer stages.

The centrifugal compressor is definitely a continuous-duty unit because its service life is unaffected by full-load operation. However, it is also a relatively sensitive machine because it operates at high speeds — often as high as 50,000 rpm. Ambient factors which affect flow are altitude, inlet air temperature, and the relative humidity of inlet air. The operating life of this type of unit is primarily determined by the amount of entrained liquids and solids carried into the unit at the inlet — and the quality of the cooling water. As in all machinery, correct installation and maintenance is critical to the efficient production of compressed air and reaching a satisfactory operating life.

When a facility requires a continuous-duty, high-volume (2000 to 25,000 cfm) supply of non-lubricated air, the centrifugal compressor is one of the best choices. In fact, it is the only choice in sizes above 1000 hp. Whether or not it fits the installation best is another question to be answered after analyzing the job conditions. In any event, when correctly applied, installed, and maintained, a centrifugal compressor offers a reliable, continuous source of compressed air.

Capacity controls

Many compressed-air conservation program on the demand side target such issues as:

• identifying and repairing air leaks,

• eliminating open blowing,

• fixing malfunctioning condensate drains, and

• managing all potential inappropriate uses.

When these programs are completed successfully, often it is found that the facility consumes less compressed air for production, but electrical energy consumption does not go down proportionally. The reason: without appropriate capacity controls operating correctly on compressors, it is impossible to effectively translate lower air use into lower electrical energy input.

When working effectively, compressor-unloading controls should:

• match air supply to the demand when needed,

• eliminate or minimize system overpressure,

• maintain the necessary minimum acceptable operating system pressure,

• reduce the input power cost to the optimum point proportional to the air flow demand, and

• turn off unneeded air compressors and bring them back on when required.

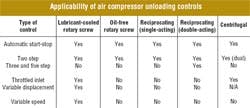

Regardless of the type of air compressor, the operating principles of capacity controls can be grouped into several basic categories. (Note that some will only perform on certain types of compressors.) Here are descriptions of these categories with some of the pros and cons of each.

Automatic start-stop control — This control simply starts and stops the electric motor or driver automatically. It can operate any type of compressor. A pressure switch usually accomplishes this function, shutting off the motor at the upper pressure limit, restarting it at the minimum system pressure.

Pro: The air compressor runs at its two most efficient modes, fully loaded and off.

Con: Most AC electric motors can survive only a finite number of starts over a given time frame, primarily due to heat build up. This limits the application of automatic start-stop controls — particularly for motors larger than 10 to 25 hp.

Con:The compressor must run above minimum system pressure to hold that pressure.

Con: The system must have adequate air-storage capacity to perform satisfactorily.

Continuous-run controls (step type) — With these controls, the driver or electric motor runs continuously while the air compressor is unloaded in some manner to match supply to demand. System pressure usually commands the unloading arrangement. Continuous-run controls can be categorized as step or modulating type.

The most common is the two-step control, which holds the compressor inlet either fully open or fully shut. Over the complete operational band, the compressor runs fully loaded (or at full flow) from the preset minimum pressure (or load point) to the preset maximum pressure (or no-load point). At the latter, the control shuts off air flow completely. The unit then runs at no flow and full idle until system pressure falls back to the load point. The control then goes immediately to full-flow capacity. A pressure switch typically actuates the two-step control, which can be either the primary control or part of a dual-control system on virtually every type of air compressor. (Some reciprocating compressors can be fitted with 3- and 5-step controls.)

Pro: The compressor runs at its two most efficient modes — full load and full idle — which results in the lowest possible input power cost. Full idle at lowest input power is accomplished almost immediately, except in the case of lubricated or lubricant-cooled rotary-screw compressors.

Con: Both correct piping and adequate air storage are necessary to allow enough idle time over the operational pressure band to generate any significant energy savings.

Con: When two-step controls are misapplied, not only is there little or no power cost savings, but short cycling (i.e.: 20 sec. on/ 20 sec. off) can damage the equipment and shorten the life of normal wearing parts.

Con: Too much backpressure in the interconnecting system can cause short cycling or ineffective unloading.

Con: At 85 to 95% loads, step controls consume some extra power because they have to compress at full capacity to a higher pressure just to hold a lower design system pressures.

Continuous-run (modulating) controls — These controls match supply to demand very accurately all along the operating band pressure range. Most incorporate some type of regulator, which in effect converts the operating pressure control band into a proportional band. If system pressure fluctuates as little as 1 psi, the modulating control immediately decreases or increases flow proportionally, depending on the signal. (This control generally is installed only on lubricant-cooled rotary-screw and centrifugal compressors.)

Pro: The minimum set system pressure draws the most power. As system demand falls, pressure rises, flow cuts back, and power usage also falls. This results in a savings at higher demand (and is the opposite of 2-step unloading where the power draw actually increases as system demand falls).

Pro: more efficient at high loads.

Pro: holds a relatively steady pressure when demand is stable, and responds responds quickly to any change.

Pro: does not depend on storage capacity to operate effectively.

Con: is generally more inefficient at lower loads.

Con: Too much backpressure in the interconnecting piping can force multiple units into running on part load, when one or more could be shut off.

Summarizing choices

|

Where to put it The compressor room ideally should be clean and dry. Auxiliary equipment, piping, and wiring should be arranged so that it does not interfere with routine inspections. Instruments should be located within easy view of operators. |

After reviewing the comments on air compressors in this article, one conclusion is fairly obvious: each design has advantages and disadvantages which must be matched to a specific application. The table above summarizes a number of selection factors for the most common basic designs. Other factors, such as air quality and installation requirements, are difficult to quantify. The unavoidable cost factor — initial, operating, and maintenance — is noted with them in the following text.

Double-acting reciprocating — Advantages: highest efficiency, longest service life, field serviceability. Disadvantages: highest initial cost, high installation cost, high maintenance cost.

Oil-flooded, single-stage rotary screw — Advantages: low initial cost, low maintenance cost, packaged design. Disadvantage: low efficiency.

Oil-flooded, two-stage rotary screw — Advantages: higher efficiency, simple packaged design, same low maintenance cost. Disadvantage: higher initial cost.

Oil-free rotary screw — Advantages: high-quality air, moderate efficiency, simple packaged design. Disadvantage: higher initial cost.

Centrifugal — Advantages: the only type available above 600 hp, high-quality air, moderate efficiency, longer service life than other rotaries. Disadvantages: higher initial cost, must be water cooled, air flow is sensitive to changes in ambient conditions.

Hank van Ormer is president of Air Power USA, Baltimore, Ohio. For more information, call (740)862-4112. or visit airpowerusainc.com.