This file type includes high-resolution graphics and schematics when applicable.

Electrical and hydraulic-system power sources, which are more accurately called energy converters, have input in one form and output in electrical or hydraulic form. Most electrical sources are generators — a term applied to numerous source types. The other type of electrical source is the alternator. Alternator is generally reserved for rotating machines — such as those used by the power company or in automobiles — that generate alternating-current (ac) power. Alternating current usually means any voltage or current that varies in a regular cyclic manner. The other types of electrical sources generate direct current (dc), although purely direct current (meaning nonvarying throughout all time) doesn’t exist

On the other hand, hydraulic-fluid power sources, pumps, are strictly mechanical, usually rotational input devices. Even though electrical sources offer a greater variety of input power media, rotational mechanical input on its own plays a key role in the hydraulics arena.

Hydraulic-power sources

Hydraulic-fluid power is based on the positive-displacement principle. In other words, the amount of fluid transferred per input shaft revolution from the inlet of the pump to the outlet of the pump is independent of the outlet pressure. A volume of fluid flows into the inlet port of the pump, which then transfers that volume of fluid to its outlet port, and subsequently expels the fluid from the outlet port. When a positive-displacement pump operates at a fixed input-shaft speed, the output flow is constant in the face of changing outlet pressure (ignoring internal leakage). That’s why positive-displacement pumps are considered positive flow sources.

Positive-displacement pumps fall into one of two categories: fixed or variable displacement. A fixed-displacement pump transfers a fixed volume of fluid for rotation of its shaft. Depending on the type of design, a variable-displacement pump transfers an adjustable volume of fluid for every rotation of its shaft. This is accomplished by changing the tilt angle of a swashplate, tilt angle of a bent axis, or by altering cam eccentricity. Some pumps can be made variable by rotating their port plates.

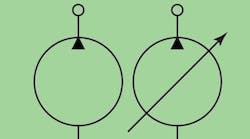

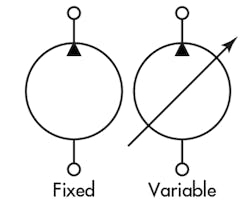

The standard International Organization for Standardization (ISO) symbols for positive-displacement pumps are developed around a circular envelope; a small arrowhead identifies the outlet port and the nominal direction of output flow (Figure 10). The arrowhead is filled in black to indicate that the pump is hydraulic. (An open arrowhead indicates a pneumatic pump, commonly known as a compressor.) An arrow across the pump symbol set at an angle about 45° from horizontal indicates that the pump has variable-displacement capability. The symbols give no clue as to the type of pump, whether it is piston, vane, gear, etc.

Hydraulic-pump types

Hydraulic pumps are categorized according to their positive-displacement principle. Major types include piston, vane, and gear, with each having its own set of additional distinguishing mechanical features.

Piston pumps fall into two categories: axial and radial. Straight-axis (axial-piston) pumps can have a straight or bent axis. Axial-piston pumps reciprocate pistons by rotating a barrel and pistons against a tilted swashplate. Bent-axis pumps, however, produce reciprocation by rotating the barrel against an angularly offset cam plate. When variable, the swashplate angle is changed in the straight-axis and bent-axis pumps, respectively. Radial piston is a third variety. In this design, pistons are position perpendicular to the input shaft. All three designs use check ball or port plate commutation, which refers to the method of converting the internal reciprocating flow into steady, unidirectional flow. They can also be fixed or variable displacement, although radial-piston pumps are usually fixed displacement.

Vane pumps have either a single cam lobe, meaning one pumping cycle per input shaft revolution, or use a multilobed cam, meaning multiple pumping cycles per revolution. Both have port-plate commutation. Single-cam-lobe vane pumps can be fixed displacement or variable, where cam eccentricity is adjustable in variable versions. Multilobed-cam types can only be fixed displacement.

Gear pumps can feature external gears, where commutation is inherent in the inlet and output port construction. Other types have internal gerotor gears, which perform port-plate commutation. No practical means exist for making gear pumps displacement variable.

Electrical power sources

Although input energy media for electrical power sources are wide ranging, a few predominate over others. For example, batteries convert chemical energy directly into electrical energy. In the broader context of electrical sources, some subtleties deserve explanation.

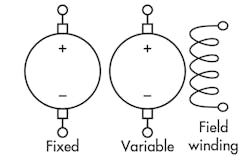

First, the word “generator” is a generic term that can suggest almost any kind of electrical source. Its literal interpretation, though, is a rotating machine (Figure 11) that includes an armature filled with windings connected to a commutator (small rectangles above and below the main circle). The commutator comes in contact with brushes that carry current from inside the rotating armature to the stationary external circuits.

To generate voltage and current, the machine needs a stationary magnetic field that immerses the armature. The magnetic field can come from a permanent magnet or a stationary field winding. The armature’s spinning windings have a voltage induced due to Lenz’s law. If the stationary magnetic field originates from a permanent magnet, the generated armature output voltage depends only on the generator’s speed. If it results from the field winding’s electromagnet, field current can be altered to change the magnetic field, resulting in a variable voltage generator — even if the speed is held constant. In that respect, the field winding is analogous to the variable-displacement pump, in which the field winding and its current “change the displacement” of the generator.

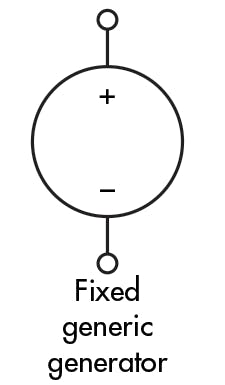

On the other hand, a generic generator symbol (Figure 12) lacks a field winding and the brushes. The form shown is an unknown and unknowable type. Sometimes the symbol is used for any one of the devices described below.

A second point regarding electrical power sources revolves around the myriad signal sources. The term signal applies to extremely low-level voltages or currents created, for example, as outputs from a pressure or position transducer. The signal is used to control other electrical or electrohydraulic devices. They must be distinguished from power sources, which indicates that they can provide high currents, voltages, and power.

Third, low-power-level ac sources are used for certain control functions and excitation for some transducers, such as LVDTs, or as timing signals in electronic watches or clocks. Referred to as oscillators or local oscillators, they generate a regular, cyclic ac output, usually of fixed frequency and amplitude and often in the shape of a sinusoidal wave.

Key electrical sources

Some of the more important electrical sources, both at the power and signal level, include batteries, generators, alternators, signal sources, solar cells, electronic power supplies, and transducers.

Batteries have chemical input energy sources. They always produce dc output and generate a fixed-output voltage. They are the primary power source in most mobile electronic devices, although discharge is a constant nuisance. Liquid electrolyte-type batteries, such as lead acid for automotive applications, are capable of very-high power levels in a relatively small package. Dry-cell batteries include alkaline, nickel cadmium (NiCd), and lithium ion (Li-ion). The rechargeability of low-power-density alkaline batteries requires the right batteries and right charger. High-power-density NiCd batteries are rechargeable, but require special procedures. Li-ion batteries have the highest power density, and are rechargeable.

Generators maintain a mechanical energy input, usually a rotating shaft. They generate dc power, and output voltage is proportional to input speed. Certain generators can produce adjustable output voltage. Brushes connect their internal rotating components to the stationary outer world.

Alternators, generally used by power companies, can deliver up to 100 A at 12 Vac. They’re often found in automobile charging systems. In these systems, rectifying diodes — integral to the alternator structure — convert ac to dc. Such systems can recharge lead-acid batteries.

Signals and signal sources are generated by all types of transducers and sensors. They’re received by antennas as radio signals and, in turn, transmitted in all wireless devices.

Solar cells convert light energy into electrical energy without moving parts. Voltage amplitude and current depend on incident light intensity.

Electronic power supplies receive power from ac power lines in homes, offices, factories, etc. They require diodes to convert ac into dc power, and transformers to change output-voltage level from line-voltage level. Such supplies are the primary power source in stationary electronic devices and can be made with adjustable output voltage. Similar in behavior to batteries, power supplies offer more constant output voltage attributed to built-in regulators, and they never lose their charge. However, they do require an extension cord from a wall outlet to the power supply.

Transducers generate signal-level voltages, sometimes currents, which depend on the measurement of some variable, such as pressure, temperature, rotational speed, etc. There are too many possibilities to list in this general discussion, though.

Summary

Electrical and hydraulic sources, recognized as energy converters, convert energy in one form into electrical and hydraulic energy, respectively. The hydraulic source tends to produce an output flow due to its positive displacement. That flow, which depends mostly on the input shaft speed, is relatively unaffected by the pump’s output pressure. Thus, it’s called a positive-flow source.

In contrast, an electrical generator’s natural tendency is to produce a positive voltage. In this context, positive isn’t meant to be algebraic polarity or sign, but rather it infers that the voltage remains unaffected by the amount of output flow, that is, the output current. Now, if these two different sources were perfectly analogous, the hydraulic pump would be a positive pressure source, or the electrical generators would be positive current sources. In other words, the analogies diverge due to the way the two sources are constructed. But it raises the question: “Are there positive pressure sources and are there positive current sources?” The answer is an emphatic “YES.” The next installment will explore the variations and possibilities.