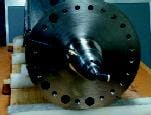

End view of roll shows journal bearing with pneumatic input connector and rotating collar that delivers air to bladder.

Add unbalanced mass to the surface of any rotating machine element and you present a challenge to the element's bearing system. That was the situation facing Agfa Corp. designers working on external drum plate-setters for a web-type printing press. They needed a clamp to hold down the flexible aluminum printing plate that wraps around the 4-ft wide, 1-ft diameter roll. Their problem: with the roll spinningat 300+ rpm, any excess mass in the clamp would create centrifugal forces that would strain the roll's journal bearings, eventually causing it to wobble — and the platesetter to improperly image.

Prototype designs centered on a two-piece, piano-type sheet-metal clamp mounted longitudinally on the roll's surface. The clamp could be opened and closed with a magnet-and-spring arrangement or with a small hydraulic actuator. Both schemes worked in prototyping, but they were heavy, quite expensive, and were projected to be a wear and maintenance headache. In addition, because the clamping force was inconsistent along the clamp's length, the printing plate sometimes tore during test runs.

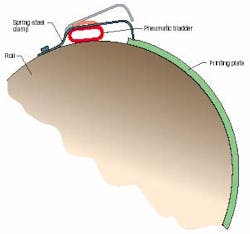

A redesign, which focuses on an inflatable Presray Pneuma-Seal bladder — from Pawling Engineered Products — eliminates those concerns. The long slender bladder is made of fabric-reinforced EPDM and nestles underneath a one-piece, press-formed spring-steel clamp; both run all the way across the roll. With the bladder exhausted, spring properties of the steel strip keep the clamp in its closed position with uniform clamping force across the entire roll width. When 40-psi air is delivered to the bladder (through a rotary pressure collar on the roll's journal bearing), the bladder expands 1/8 in., enough to push the clamp open and release the printing plate. The opening force is uniform across the entire length of the clamp.

The bladder is secured only at its ends. Frictional contact with the clamp over its entire length holds the rest of it in place. In effect, the clamp squeezes the bladder in place, whether inflated or deflated. The clamp's maximum duty cycle is a hundred cycles per shift, so a single inflation point is sufficient for this application.

In the simpler, redesigned pneumatic clamp (patented by Agfa), the bladder weighs twothirds less than either prototype alternative, and the spring-steel clamp weighs about onequarter as much as the piano hinge. In addition, there are no electrical or mechanical linkages to wear out. The bladder and clamp simply flex to create the desired action. Parts are fewer and assembly costs are lower. Rated service life of the bladder exceeds the platesetter product life cycle of seven years or more.

Cross sectional view of clamping assembly. Bladder measures 48 in. long X 7⁄8 in. wide X 5⁄16 in. high. It has 0.094 in. thick walls and weighs only 5 oz.

For more information on Presray Pneuma-Seal pneumatic actuators, contact Pawling Engineered Products, Pawling, N.Y., or visit www.pawling.com