It has been reported that the absence of concrete reinforcement is the main reason why so many buildings collapsed during Haiti’s tragic earthquake causing the needless deaths of tens of thousands of people. But if the earthquake had been less severe — and only one building fallen down — the prolific nature of the problem may have gone unnoticed.

The latter situation is similar to what is going on in the fluid power industry. Rarely do we see wide scale failure of entire systems that leads to injury or death. Rather, when accidents result in serious consequences, they are usually viewed as isolated incidents — unrelated to accidents occurring elsewhere.

But most of these accidents are related. The common thread is organizations that either produce inadequate safety requirements or none at all. But the problem is more serious than just a lack of safety instruction. Many people specifying components for fluid power systems or working on them lack the education or training to be qualified to do so. Consequently, they repeatedly engage in reckless and unsafe practices and don’t even know it. Sometimes they are lucky that their actions don’t produce catastrophic results. But if fate were to cause catastrophic results in a single day from all the unqualified people working on fluid power systems, the widespread catastrophe would certainly bring the matter to national attention. In a sense — and only to make a point — not enough people are getting injured or killed in a single incident for the issues to receive national attention.

These problems in the fluid power industry can be distilled down to:

- sub-standard engineering practices,

- sub-standard material specifications,

- sub-standard building practices,

- code violations, and

- poorly trained building workforce.

Not enough space exists in this issue to examine each of these problems in depth, so this discussion will focus on those directly affecting the maintenance, repair and overhaul sector.

Sub-standard engineering practices — Mechanical engineers undertake the vast majority of hydraulic system design. They take courses in a branch of hydraulics called fluid dynamics. However, knowledge of fluid dynamics alone does not make an engineer fully competent to design hydraulic systems, and it certainly doesn’t aid engineers in designing safe hydraulic systems. The Fluid Power Safety Institute’s slogan describes the issue of safety and engineering best: Fluid power safety doesn’t just happen. It has to be pursued.

To my knowledge, no university in the US teaches engineers safe hydraulic design practices. We don’t assume that engineering students have an innate knowledge of math, physics, chemistry, etc. If we did, why would students be required to take so many courses in these subjects. It seems as if the fluid power industry embraces the notion that people who design hydraulic systems do have the innate ability to design in safety because it’s so hard to find any institution that teaches safety.

Sub-standard material specifications — It’s highly unlikely a mechanical engineer will design a hydraulic system with sub-standard materials. However, the fluid power industry does not dictate who can and cannot design hydraulic systems. While many salespeople are mechanical engineers, non-engineers routinely assist clients with hydraulic system design or modification. This is invariably where the problem of sub-standard material specification rears its ugly head. Untrained personnel routinely specify components with marginal pressure and flow ratings.

Substandard building practices — The people who build hydraulic power units, construct vast plants, and assemble construction, agricultural and mining machinery are called assemblers. Like the hose and fitting industry, the vast majority of plant and machinery manufacturers don’t teach their assembly line workers hydraulic safety or basic hydraulics. Ironically, the tasks assembly line workers do have a profound effect on the safety and reliability of the machines they build. Also, assembly line worker training has been proven to dramatically reduce a company’s warranty claims.

Code violations

Less than 1% of the hydraulic systems in operation today comply with the Occupational Health & Safety Administration’s (OSHA’s) Energy Control Procedure 1910.147 (c)(4)(i), which states: “Procedures shall be developed, documented and utilized for the control of potentially hazardous energy when employees are engaged in the activities covered in this section.”

Under each of eight steps, the violation will be noted in bold text. However, the employer need not document the required procedure for a particular machine or equipment, when all of the following elements exist:

1. The machine or equipment has no potential for stored or residual energy or re-accumulation of stored energy after shut down which could endanger employees.

Response: Less than 1% of the hydraulic systems in the US — and abroad, for that matter — comply with this rule. More than 99% of hydraulic systems store energy after shutdown, which endangers employees

2. The machine or equipment has a single energy source, which can be readily identified and isolated

Response: Hydraulic systems store energy in pockets or zones. Few hydraulic systems have a single energy source. In the few that do, the energy source cannot be readily identified or isolated.

3. The isolation and locking out of that energy source will completely de-energize and deactivate the machine or equipment

Response: The energy sources in 99% of hydraulic systems cannot be locked out and will not completely de-energize

4. The machine or equipment is isolated from that energy source and locked out during servicing or maintenance

Response: Electric motors can be locked out at the panel, but that does not isolate the energy source (hydraulic system) during servicing or maintenance. However, there is no standardized lockout device for battery-operated starting systems for internal combustion engines. Mechanics routinely ignore lockout because of the inconvenience of having to disconnect battery cables

5. A single lockout device will achieve a lockout condition

Response: A single lockout device will not achieve a lockout condition in a hydraulic system

6. The lockout device is under the exclusive control of the authorized employee performing the service or maintenance

Response: The lockout devices in hydraulic systems cannot be under the exclusive control of the authorized employee because they cannot be locked with a padlock and are usually out of sight.

7. The servicing or maintenance does not create hazards for other employees

Response: The servicing or maintenance of a hydraulic system will always create a hazard for other employees who might be standing in harm’s way. Examples include unexpected movement when connector is loosened, getting sprayed with hot oil, unexpected movement of a propelled vehicle, etc.

8. The employer in utilizing this exception has had no accidents involving the unexpected activation or re-energization of the machine or equipment during servicing or maintenance.

Response: Employers invariably have zero accidents pertaining to unexpected release of hydraulic energy for two reasons. First, Untrained personnel are unaware they suffered a non-injury accident. Second, less than 1% of companies that participate in non-injury accident reporting report non-injury accidents related to hydraulics

In a nutshell, the only way to determine if there is stored energy in a hydraulic system and remove it is to “crack” (loosen) a connector, allowing the stored energy to discharge to atmosphere. This common (and accepted) practice leaves maintenance personnel susceptible to a host of debilitating injuries, including eye injuries or blindness, burns, oil injection injury, etc.

Ironically, the very same manufacturers that design and build inherently unsafe hydraulic systems (from a lockout point of view) admit to the safety hazards associated with discharging high-pressure oil to atmosphere because they warn personnel about it. Their generic warnings go something like this:

“Warning – discharging high-pressure oil to atmosphere can cause severe injury, death, or substantial property damage. Completely remove stored energy before loosening fittings or disconnecting transmission lines.”

The inconsistency between their warnings and the complete absence of any way to safely de-energize their hydraulic systems seems to confirm a communication disconnect between their legal departments and their technical publications departments.

Who’s to blame?

Clearly, the lion’s share of the blame goes to organizations like OSHA and the Mine Safety & Health Administration for failing to hold the fluid power industry accountable for building inherently unsafe hydraulic machinery.

Machinery and equipment manufacturers must also shoulder the blame because they are clearly in violation of a law, which is designed to prevent injuries and save lives. I have discussed the issue with engineers from a broad range of companies, and the excuses are consistent. The most common are:

- “Why should we add expensivesafety features to our machines if they are not required by law?”

- “Why should we add safety features to our machines if our competitors don’t?”

- “If we add safety features to the machines we design and build today, we are confessing that the machines we built yesterday are unsafe.”

Safety personnel

The duty of a corporate safety officer is to see to it that no safety law is overlooked. They need to practice what they preach. Lockout/tagout should be more than just a classroom lecture; it should be akin to a fire drill. Safety personnel will quickly realize the inherent dangers associated with hydraulics when they reach to loosen a transmission line and find vast amounts of stored energy, which manifests itself as fluid gushing from the open line.

Less than 5% of the maintenance personnel that maintain the nation’s plant and equipment receive adequate hydraulic training. The vast majority receive none at all. The only reason why maintenance people haven’t laid down their tools is because these workers aren’t well enough trained to identify the monster they are dealing with.

This situation will not change until the responsible organizations decide that there is more to a hydraulic system than meets the eye. Like an electrical system, a hydraulic system offers a host of hazards that only properly trained personnel are equipped to identify and safely handle.

Maintenance people must respectfully challenge authority. If you are taught about lockout/tagout and de-energization and verification, ask how it is safely accomplished. Have the instructor demonstrate de-energization procedures in your plant. The very reason why OSHA and MSHA devised lockout procedures — and issues citations to corporations that do not abide by the procedures — was to save life and limb. You have a right to work safely, and machinery and equipment manufacturers have a moral and ethical obligation to build safe machinery.

Rory McLaren is president, Fluid Power Training Institute, Salt Lake City. For more information, e-mail him at [email protected] or visit www.fpti.org.

A case in point

A mechanic, looking to replace a damaged hose, stops into his local hose and fitting distributor to have a replacement made. He handed the damaged hose to the counter salesman as a template. The salesman took the hose, disappeared into the workshop, and returned a few moments later with the news he was out of that particular hose, say, SAE100R2.

Instead of doing the right thing and recommending that the mechanic try another dealer, the salesman asked the mechanic if he knew the machine’s pressure relief valve setting. The mechanic replied 2000 psi, whereupon the salesman remarked that the SAE100R2 hose was “overkill” and that SAE100R1 would be a satisfactory substitute.

Within an hour of leaving the store, he had the first of two non-injury accidents. Within minutes of installing the new hose it ruptured when the hydraulic cylinder was put into motion. The mechanic removed the hose and returned it to the store. The salesman apologized for the inconvenience and promptly made an identical assembly, which also ruptured when the hydraulic cylinder was once again put into motion.

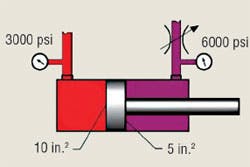

Had the counter salesman or mechanic received training in basic hydraulics, they would have learned that a hydraulic cylinder, without load intensifies pressure when equipped with a flow control valve for metering oil out of the rod end.