Analogies exist between hydraulic flow and electrical flow, and the molecules of fluid in a hydraulic circuit behave much like the electrons in an electrical circuit. Let’s examine analogies between pressure and voltage and between ground and the hydraulic reservoir.

Molecules and electrons

When a valve shifts to power a hydraulic motor, the motor does not react instantaneously, but shortly after the valve is shifted. This is because the molecules within the motor start moving with a time delay governed by the speed of sound and the physical dimensions of the circuit. On the other hand, an individual molecule of fluid inside the pump when the valve shifts may require seconds, or minutes, before it actually passes through the motor — well after the motor shaft started turning.

Similarly, it can take minutes, or even hours, before an individual electron inside a generator makes its way into a load, such as an electric motor. Yet, the electric motor reacts to the closing of a switch with a time delay that is governed by the speed of light. These concepts are useful because they lead to an understanding of why electronic and hydraulic devices do not always appear to react instantaneously.

Pressure and voltage

Pressure is what drives the movement of fluid molecules from a region of high pressure to a region of lower pressure. The hydraulic pump raises the energy content of the fluid in the form of elevated pressure, and the higher pressure at the pump sends energized fluid into the load to do useful work. The fluid particles experience ever-diminishing pressure as they make their way around the circuit and ultimately back to the reservoir. Voltage is analogous to pressure, and it is what drives the electrons to migrate from regions of high voltage to regions of low voltage.

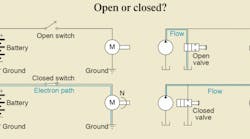

Consider the simple electrical circuit diagram on the left side of Figure 1, which shows a battery, switch, motor, and connecting wiring that ties the components together and to ground. The purpose of this circuit is to be able to turn a motor on and off. The hydraulic complement of the simple motor circuit is shown on the right side of Figure 1.

The battery symbol is a series of alternately long and short parallel lines. The longer line denotes the positive terminal of the battery, and the shorter, the negative. The battery symbol gives no clue as to construction. It could be the lead-acid type used in cars, an alkaline type found in flashlights, or a lithium-ion type for a laptop computer. Likewise, the pump symbol used in hydraulics does not designate the type of construction — it could be a gear pump, vane pump, or piston pump.

Open or closed?

The switch symbol is generic, but it implies a moveable blade that engages two leaves that pinch the blade to make electrical contact. When the contact is made, we say the switch is closed, and here is one of the sources of confusion when coming from a world of hydraulics to the world of electronics. Closing a switch is analogous to opening a valve.

One of the most fundamental laws of electricity is that electrical current must always close on itself, thus, the current describes and follows a complete closed path. In our simple circuit, this means that for every electron leaving the negative terminal of the battery, one electron must enter the positive terminal. A complete loop must exist in order for current to flow.

Some of the imperfections in the analogies occur because the electrical circuit uses a constant voltage source (battery), whereas the hydraulic circuit uses a constant-flow source (positive displacement pump). When the hydraulic bypass valve is open (flowing), there will be a small pressure felt by the motor, and the motor shaft may even rotate if there is no load on it.

In the upper left circuit in Figure 1, the loop is open, so there can be no current. In the lower circuit, the loop is complete, so there is current; the motor is powered, so it turns. So when we “close the switch,” we really mean we close the circuit.

Getting well grounded

Ground is a term that can lead to confusion because of the way it is used, especially in electronic control systems. The term ground derives from the fact that mother Earth is used as a conductor by the electrical power industry. In the wiring of your house, for example, electrical codes require that part of your house wiring (the green wire) must be connected to mother Earth. That wire eventually leads to a stake driven into mother Earth or a physical connection to a water pipe that is buried underground. The term ground has evolved into one that means any common point in a circuit to which all circuits return, which may not necessarily be mother Earth.

Placement of the ground in the electrical circuit of Figure 1 is similar to how the reservoir is connected in the hydraulic circuit. Ground and reservoir are analogous terms. We could define the reservoir as that point in the circuit to which all fluid must return. However, designers of electronic circuits have more flexibility in defining ground than hydraulic systems designers have in defining where the reservoir is located.

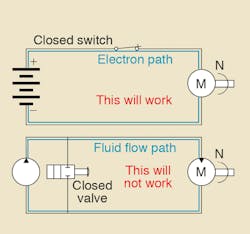

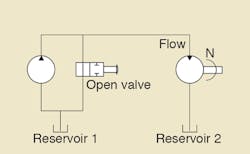

The electrical circuit of Figure 2 has no ground at all; yet, the circuit will function perfectly well. In analogous fashion, the reservoir has been removed from the hydraulic circuit of Figure 2. This creates a potential for cavitation because no means has been provided to keep the lowest pressure above that which will result in cavitation. The reservoir in Figure 1 allows motor outflow to occur at ambient pressure, and the pump inlet is aided by atmospheric pressure as it fills.

An electrical circuit cannot cavitate. Voltages can go as far negative as is necessary to satisfy the laws of electricity, and there is no such thing as absolute zero voltage. However, there is an absolute zero pressure: a perfect vacuum. Even though a perfect vacuum cannot be achieved, if the pressure in a hydraulic system falls a small amount below atmospheric pressure, dissolved gasses come out of solution (outgassing), which leads to cavitation damage.

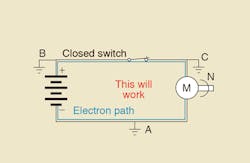

Ground location is different. In general terms, and with few well-defined exceptions, the circuit ground can be placed anywhere. For example, the circuit in Figure 3 has three different ground points. Each represents an optional choice for ground location. Only one can be chosen, but it makes no difference which one. Such is not the case in placing the reservoir of a hydraulic circuit. The reason? Pressure anywhere in the system cannot be allowed to fall below atmospheric, otherwise cavitation may occur.

Mother Earth vs. ground

A common misconception holds that ground (mother Earth) is a body that will suck up any electricity thrown at it. This is simply not the case. It is merely one conductor in the electrical power grid because the power industry chose to connect one side of their alternators to mother Earth many years ago.

I often ask my students, “What would happen if you took a metal stake, drove it into the ground about two or three feet, and then connected a jumper cable from your car battery’s positive terminal to the stake?” The answer: Nothing! A complete loop is not formed from the positive battery terminal, through the blue jumper cable, through the stake, and through Earth. The tires, being electrical insulators, prevent any current from flowing through the jumper cable and mother Earth.

The electrical circuit of Figure 2 has no mother Earth connection at all, so it has a floating ground. That is, whatever point we designate as ground, however arbitrary, has a voltage relative to mother Earth that is undetermined and unimportant. Billions of circuits are functioning right now that have no connection to ground whatsoever. They are battery-powered toys, flashlights, cell phones, even airplanes. The nearest analogy we have in hydraulics to a floating ground is in the case of a sealed and pressurized reservoir. In such a system, the lowest pressure point floats above atmospheric pressure by an amount equal to the reservoir pressurization value.

Some electronic control devices are designed with a kind of local ground, or common point — an electronic reservoir that is not associated with mother Earth. I prefer to call these points common, but some circuit manufacturers persist in calling these ground, which leads to confusion because they do not mean mother Earth.

There is also confusion over positive and negative, probably because our cars are all built with negative ground (chassis) systems. There is nothing special about negative or positive, and some cars were built with positive chassis connections.

Before that, it was arbitrarily decided that electrons would be labelled as being negative. They could just as well have been labelled positive. The problem is that many electronic designers use + to designate a signal or terminal, and – to designate ground, or common. Not only can this lead to misinterpretation, but also to erroneous connections and even to danger for people and machines. I prefer to use the terms signal and ground, or common, to distinguish the two terminals.

Making connections

Electronic control system integration includes the connecting together of many electronic devices, including amplifiers, signal conditioners, computers, motion controllers, transducers, and on and on. It is absolutely necessary when building these control chains to connect the common of every device to the common of another. All of them must share the same common point.

Consider a hydraulic analogy, Figure 4. If a circuit has two pumps, each supplied by separate reservoirs that are not interconnected, eventually all the fluid will be drawn from one reservoir and deposited into the other. Clearly, this will not work. If we fail to connect the common terminals in the electrical circuit, the consequence is more subtle, but the result is noisy (electronically speaking) operation — causing machine axes to drift, jitter, or jump around if they function at all. In the hydraulic system, all the reservoirs need to be interconnected, so do the common terminals on all the electronic devices.