Hallite Seals Americas Inc., Wixom, Mich. announced today the successful development of a new test procedure for assessing the amount of dirt and dust that enters a typical hydraulic system through a cylinder's rod wiper. Developed in cooperation with Milwaukee School of Engineering’s (MSOE) Fluid Power Institute, the test breaks new ground because it features a novel methodology for measuring dry particles attributed to being a major cause of hydraulic system inefficiency, degradation and failure. It also fills a critical need for manufacturers of hydraulic cylinders.

The rod wiper located in the sealing configuration of a hydraulic cylinder is designed to limit the ingression of dirt, dust and grit, making it one of the most critical system components. However, there is no specific ISO method for testing a rod wiper’s ability to prevent particles larger than 4, 6, and 14 µm from entering a hydraulic system. These microscopic particle sizes are most damaging to hydraulic systems as referenced in ISO 4406 for coding contamination levels in hydraulic fluids.

“The MSOE rod wiper test uses an online particle counting method instead of traditional gravimetric measurement where particles are weighed,” explained Chuck White, Business Development Manager for Hallite. “The particle count approach provides a more complete and accurate assessment of contaminants than weight because two samples can have the same gravimetric weight in oil, but one may contain many more dirt particles than the other indicating much greater potential for damage to precision components. This new method raises the bar on keeping solid contaminants out of the system now to avoid problems later.”

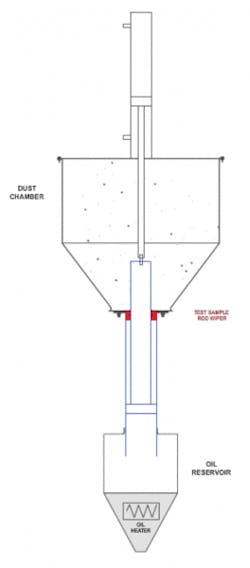

The test procedure

MSOE used the SAE J1195 standard combined with best practices to establish a baseline for developing the rod wiper test procedure. A rig was built in the MSOE test lab and parameters such as duration, cycle rate, pressure and temperature were set using input from hydraulic cylinder manufacturers to best simulate the rigor of actual field conditions. It took eight months of development, verification, trials and adjustments to establish a repeatable test procedure. Once the new procedure was completed and proven, MSOE tested the Hallite 520 and 820 wipers against two seals from other manufacturers.

The test procedure involved installing the rod wiper into the specified test fixture, heating the hydraulic circulation fluid to150˚F, pumping the oil over the top of the rod and letting it drain down into the reservoir while circulating high-velocity particles (ISO 12103-1-A4 Course Test Dust) of contamination in the chamber. The objective was to count how much dirt and grit got past the wiper. Based on the conditions and method used, data suggests that the Hallite 520 and 820 wipers allowed less than one half the amount of contaminant from entering into the test system compared to competitive wipers that were tested.

“Hallite has a reputation as a trusted brand for wiper technology, but we needed competitive third-party validation for the integrity of our material and design,” continued White. “We are very excited about the performance results because they demonstrate how our products work in some of the most aggressive field environments. Also, working together with MSOE and key customers to develop and conduct a test of this quality is invaluable as it forged a three-way partnership that emphasizes the importance of rod wipers and gives Hallite an opportunity to demonstrate our continued commitment to understanding and developing technologies to improve the effectiveness of hydraulics systems.

Finally, by cooperating with one of the leading academic fluid power research laboratories in the nation where students are building and managing the mechanical functions for test fixtures, Hallite is providing real-world interaction to help the next generation of hydraulics engineers learn more about seals and how they interact. This paves the path for innovative future testing methods.”

About Hallite — Hallite is a manufacturer of high-performance hydraulic seals and selaing systems, such as rod wipers, gaskets, rubber and plastics parts for a variety of applications in mining, construction, agriculture, and material handling. Engineered in a wide variety of advanced materials, the full range of products are readily accessible through Hallite’s global manufacturing presence and a worldwide network of service partners. Hallite is a member of the Fenner PLC Group of companies. For more information, visit www.hallite.com.

About the Fluid Power Institute — MSOE’s Fluid Power Institute (FPI) has been a pioneer in motion control and fluid power education since its inception in 1962. FPI has active programs in fluid power systems design, electrohydraulics, test and evaluation, fluid development, and contamination control. FPI recently added a new off-campus 12,500ft2 laboratory facility to support the R&D needs of the fluid power Industry. This high-bay laboratory has drive-in access, reconfigurable workspaces, and multiple power units for realistic endurance testing of fluid power equipment. For more information, visit www.msoe.edu/fpi.

A white paper describing the MSOE test and a graphic animation depicting how it was conducted are available upon request by emailing Lisa Gentile, Marketing Manager at Hallite Seals Americas, at [email protected].

For additional information, contact Lisa Gentile or Tom Wanke, Director of the Fluid Power Institute at MSOE at [email protected].