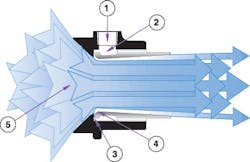

When air, vapors, or light materials must be moved easily and inexpensively, air amplifiers provide a simple solution. These devices use the Coanda effect — the tendency of a fluid stream to be attracted to a nearby surface — to create air motion in their surroundings. Using a small amount of compressed air as their power source, air amplifiers pull in large volumes of surrounding air to produce high-volume, high-velocity outlet flows up to 25 times their consumption rate.

In one application, an automotive machine shop that manufactures disc brakes was having difficulty with chip buildup inside one of the parts. Flattened compressed air tubing didn’t solve the problem — it caused high sound levels, high compressed air use, and safety issues.

Replacing the tubing with a Model 120021 11⁄4 in. Super Air Amplifier from Exair Corp., Cincinnati, solved the problems. It provided a larger pattern of air, used less air, reduced noise, and couldn’t be dead-ended. In addition to the Super Air Amplifier, the company offers a variety of other models, including high-temperature and stainless-steel designs.

Air amplifiers offer maintenance-free operation as they have no moving parts. Flow, vacuum and velocity are easy to control, while outlet flows are easily increased by opening the air gap. Supply air pressure can be regulated to decrease outlet flow.

They offer a variety of advantages over other air blowing tools and devices — for example, unlike fans they do not require electricty or moving parts and offer no RF interference. When compared to venturis and ejectors, they also win out, because they provide more air flow with less compressed air consumption, higher flow amplification, no internal obstructions, and less noise.

Learn more about how air amplifiers work at www.exair.com or call (513) 671-3322.