Engineers who design trash compactors have always had two overriding concerns. First, because of the nature of their equipment, they never know what strange objects users may throw into it. Second, it is likely that unskilled or uncaring operators will be put in charge of it. Lately, a third challenge has been added: purchasers want compactors that are energy efficient.

Model 365X self-contained compactors from Wastequip, Charlotte, N.C., are designed for hotels, restaurants, cafeterias, hospitals, and other sites that generate large volumes of waste every week. The company’s engineers began to address the efficiency requirement by building a 4-yd3 unit. Its charge box holds twice the amount of trash as the common 2-yd3compactors. The result: a compactor that only cycles half as often — using up to 65% less energy. Obviously, fewer cycles also extends service life, requiring fewer oil and filter changes and less frequent maintenance.

A compactor with guts

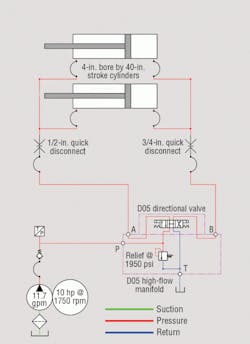

A remote pedestal houses the compactor’s hydraulic power unit (HPU), which consists of an electric motor, pump, hydraulic directional- and pressure-control valves, and reservoir. A cover shields the HPU from hostile weather conditions. There are no high-voltage electrical connections between the power unit and the compactor box — thus, no potential shock hazard with the inevitable liability. The 10-hp, TEFC Super E Series motor from Baldor Electric Co. operates at 93% efficiency, about 10% higher than comparable motors. Wastequip matches the motor with an 11.7 gpm gear pump. The HPU’s 20-gal steel reservoir is offered with an optional heater.

Two 4-in. bore, 21⁄2-in. rod packing cylinders power the compactor ram. Hydraulic connections to the power unit use dripless 1⁄2- and 3⁄4-in. quick-acting couplings — 33% larger than standard couplings normally used — to accommodate high flow. The system’s normal operating pressure is 1850 psi, with a maximum of 2300 psi.

A cartridge-type, pressure-sequenced valve system controls the packing cycle. A 3-position, 4-port valve is mounted at the power pedestal. Operation is very simple. An operator loads the container, closes the lid securely, then presses the start button for the motor. He or she then can walk away. The control valve routes pressurized fluid to the cylinder cap ends to extend their respective pistons.

When system pressure reaches 1850 psi, a pressure transducer signals the valve to shift to retract the cylinders. When the cylinders have retracted fully, the pressure transducer automatically turns off the motor. The cylinders complete a cycle in 36 sec.

Even trash compaction can use a touch of high technology these days, so Wastequip includes an infrared zero-lumens digital video camera and video monitor with the Model 365X package. The monitor provides the operator with full visibility of the loading chamber from a remote location, which can even be inside a building, for additional safety and efficiency gains.

This file type includes high resolution graphics and schematics when applicable.